Printing method of combining conventional printing with digital printing

A technology of digital printing and traditional printing, applied in the direction of copying/marking method, printing, printing device, etc., can solve the problems of good printing effect, small color gamut, low production cost, etc., to reduce production cost, good printing effect, production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

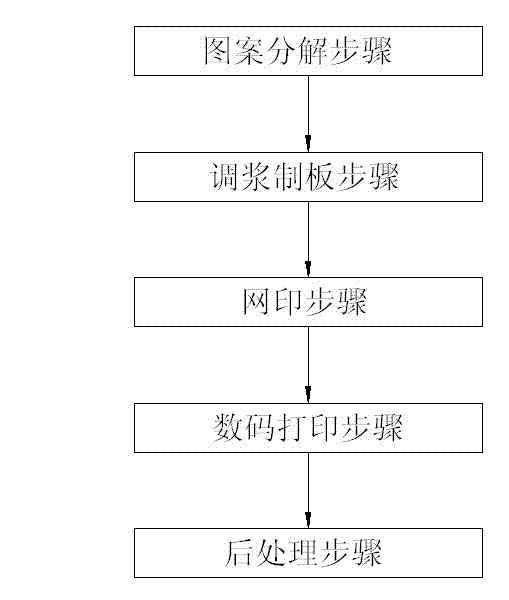

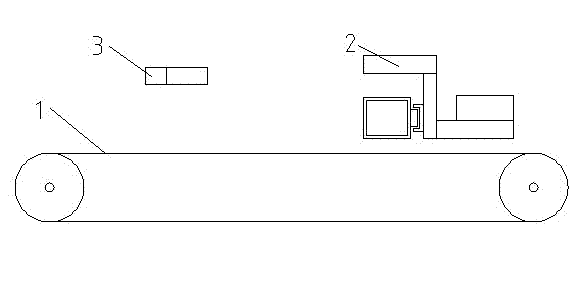

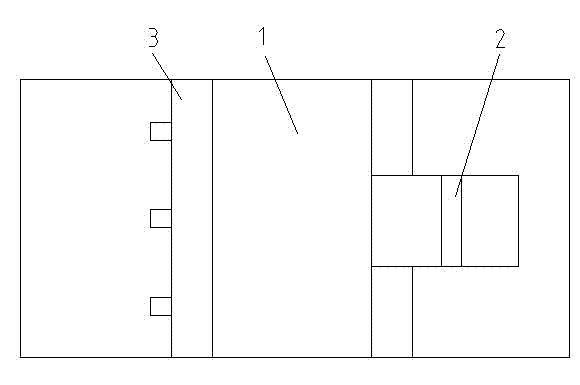

[0041] see Figure 1 to Figure 8 In this embodiment, the printing method combining traditional printing and digital printing includes the following steps in sequence.

[0042] 1) Pattern decomposition step: decompose the pattern to be printed into traditional printed patterns and digital printed patterns. Typically, traditional printed patterns are color blocks and / or patterns with large particle sizes of pigments.

[0043] 2) Slurry-making and board-making step: dye preparation is performed according to the color of the traditional printed pattern, and the board is made according to the shape of the dye and the traditional printed pattern to obtain a traditional printed pattern screen. The number of sets of boards is the same as the amount of paste; The shape of the pattern is used to make a digital printing stencil for digital printing pre-treatment, because before digital printing, pre-treatment is required, that is, pre-treatment paste needs to be printed.

[0044] 3) Sc...

Embodiment 2

[0056] seefigure 1 ,as well as Figure 9 to Figure 13 In this embodiment, the printing method combining traditional printing and digital printing includes the following steps in sequence.

[0057] 1) Pattern decomposition step: decompose the pattern to be printed into traditional printed patterns and digital printed patterns. Typically, traditional printed patterns are color blocks and / or patterns with large particle sizes of pigments.

[0058] 2) Slurry-making and board-making step: dye preparation is performed according to the color of the traditional printed pattern, and the board is made according to the shape of the dye and the traditional printed pattern to obtain a traditional printed pattern screen. The number of sets of boards is the same as the amount of paste; The shape of the pattern is used to make a digital printing stencil for digital printing pre-treatment, because before digital printing, pre-treatment is required, that is, pre-treatment paste needs to be pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com