Flat offline industrial printing printer

A printer and flattening technology, applied to printing devices, printing, typewriters, etc., can solve the problems of cumbersome replacement of boards, increased costs, and high product maintenance costs, and achieve high data transmission efficiency, reduced maintenance costs, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

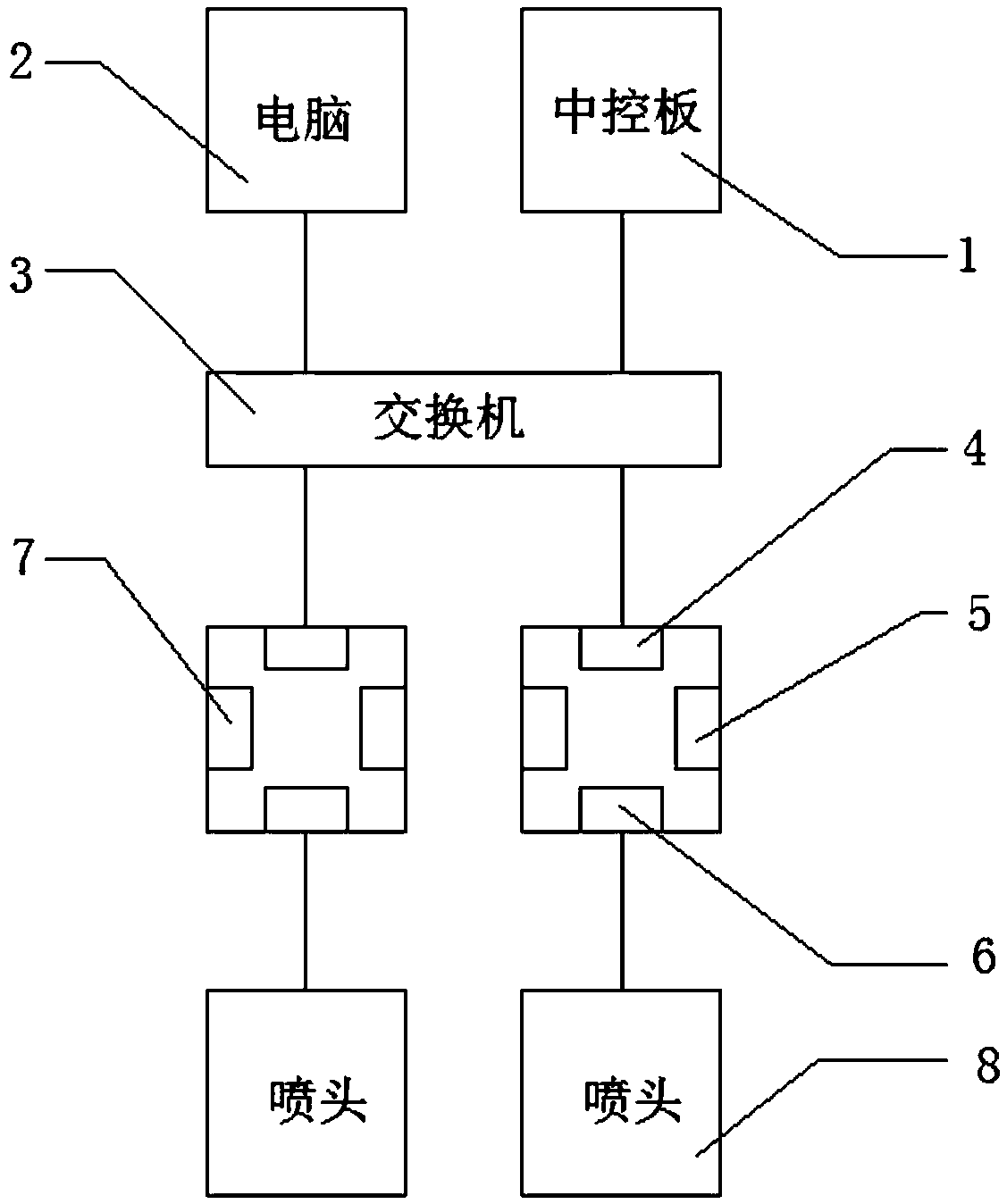

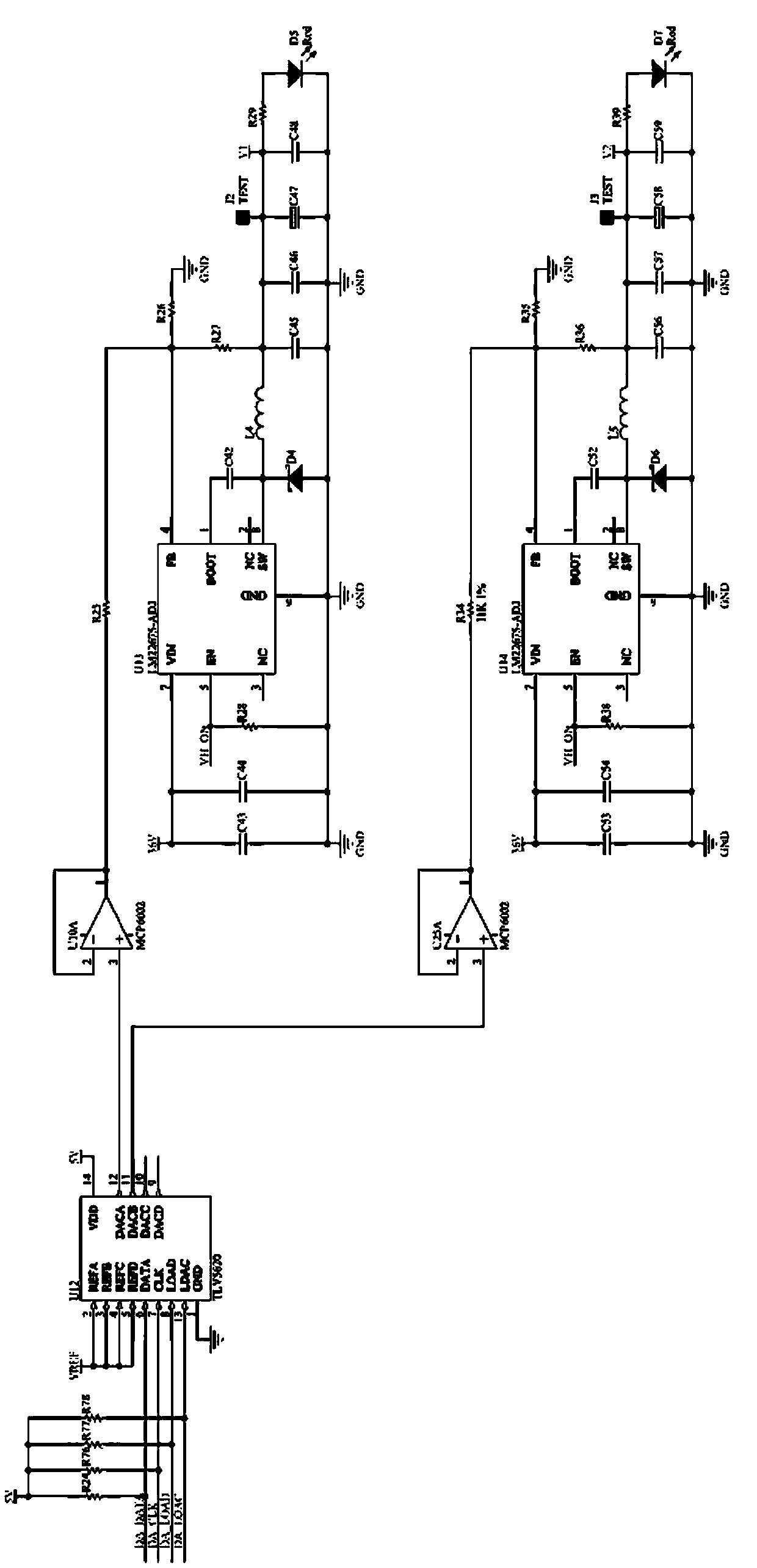

[0015] A kind of flat off-line industrial printing printer (see attached Figures 1 to 2 ), powered by a power supply, including a computer 2, a central control board 1, a switch 3 and two printing units, the computer and the central control board are electrically connected to the switch, and the switch is also connected to each of the printing The input terminals of the units are electrically connected, each of the printing units includes a nozzle board and a nozzle 8, and the nozzle board includes a nozzle driver circuit, a network interface 4, a nozzle data port 5, a serial port 6, a power interface 7 and a data Storage circuit, the power supply supplies power to the nozzle board through the power interface, the output end of the network interface and the output end of the serial port are connected to the data storage circuit, the input end of the network interface is connected to the switch, The serial port is a parameter setting input port, the print head data port is ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com