Bead-welding method of inner wall of 90-degree bent pipe

A bending and surface surfacing technology, which is applied to welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of difficult surfacing welding quality, increased manufacturing cost, and long manufacturing process, so as to avoid surfacing welding overlap Phenomenon, product quality assurance, and the effect of reducing the number of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

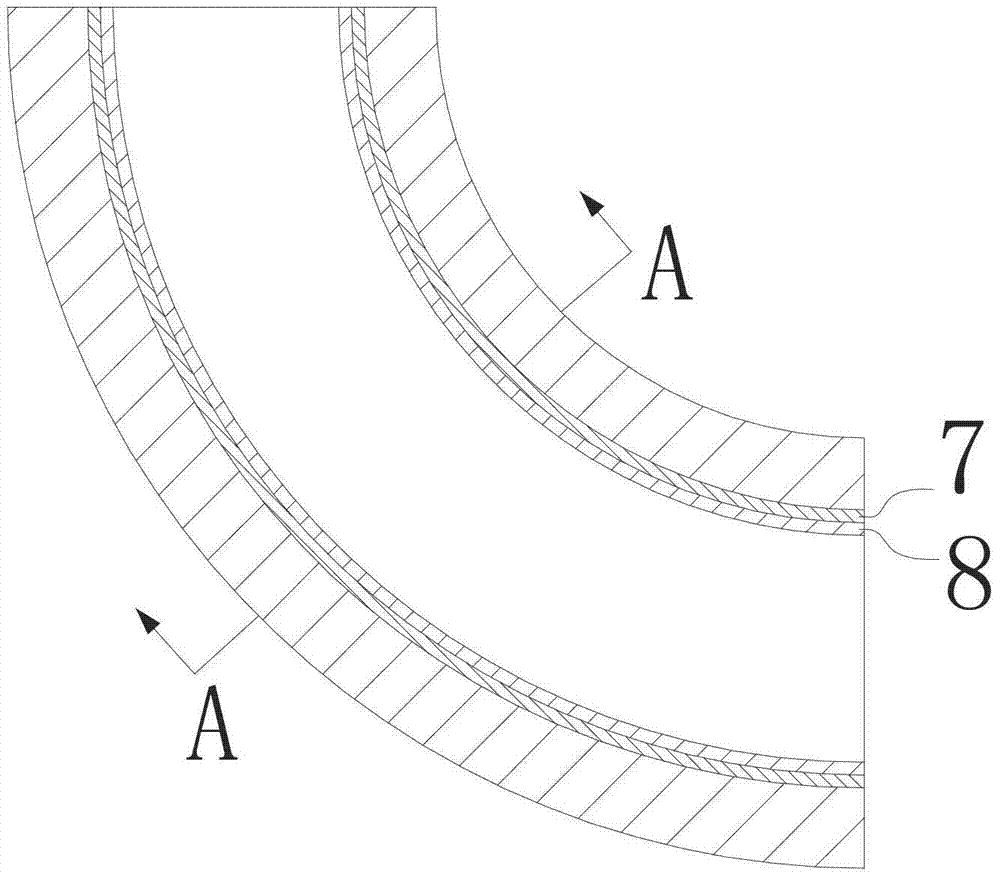

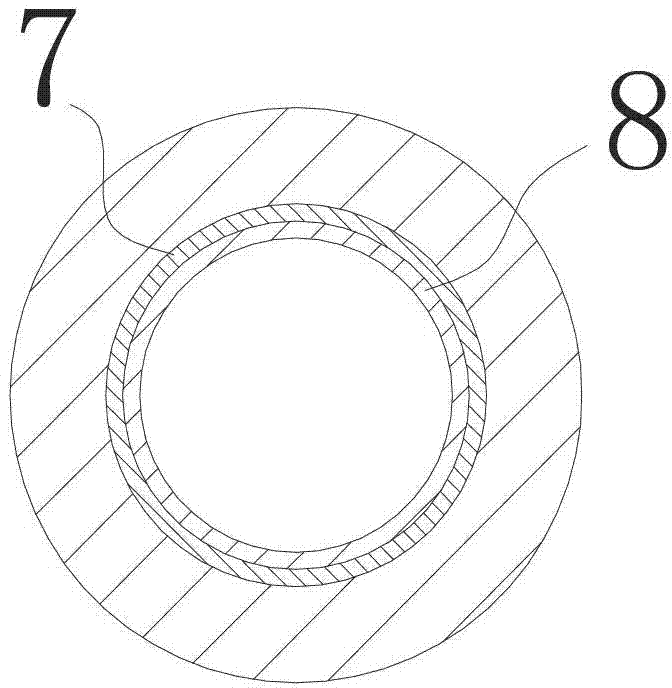

[0023] Such as figure 2 Shown, the inner wall overlay welding method of 90 ° elbow of the present invention is characterized in that comprising the following steps:

[0024] a. Select straight tube blank;

[0025] b. Heating the straight pipe billet in the furnace, taking out the heated straight pipe billet, pressing and forming it into a 90° elbow on a press, and controlling the ellipticity of the formed 90° elbow to be less than or equal to 3%; in this step, the ellipticity of the formed 90° elbow is controlled at ≤ 3%, which can ensure that the thickness of the transition layer and the corrosion-resistant layer are within the controllable range during the surfacing welding in the subsequent steps c and d. Avoid causing some places to be too thick and some places to be thinner to form quality defects; in addition, if the ellipticity of the 90° elbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com