Laser adhesive-removing process

A laser and process technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of destroying mobile phone PCB boards, spending time fatigue, scraping off solder balls, etc., to improve the yield of rework and reduce consumption time, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

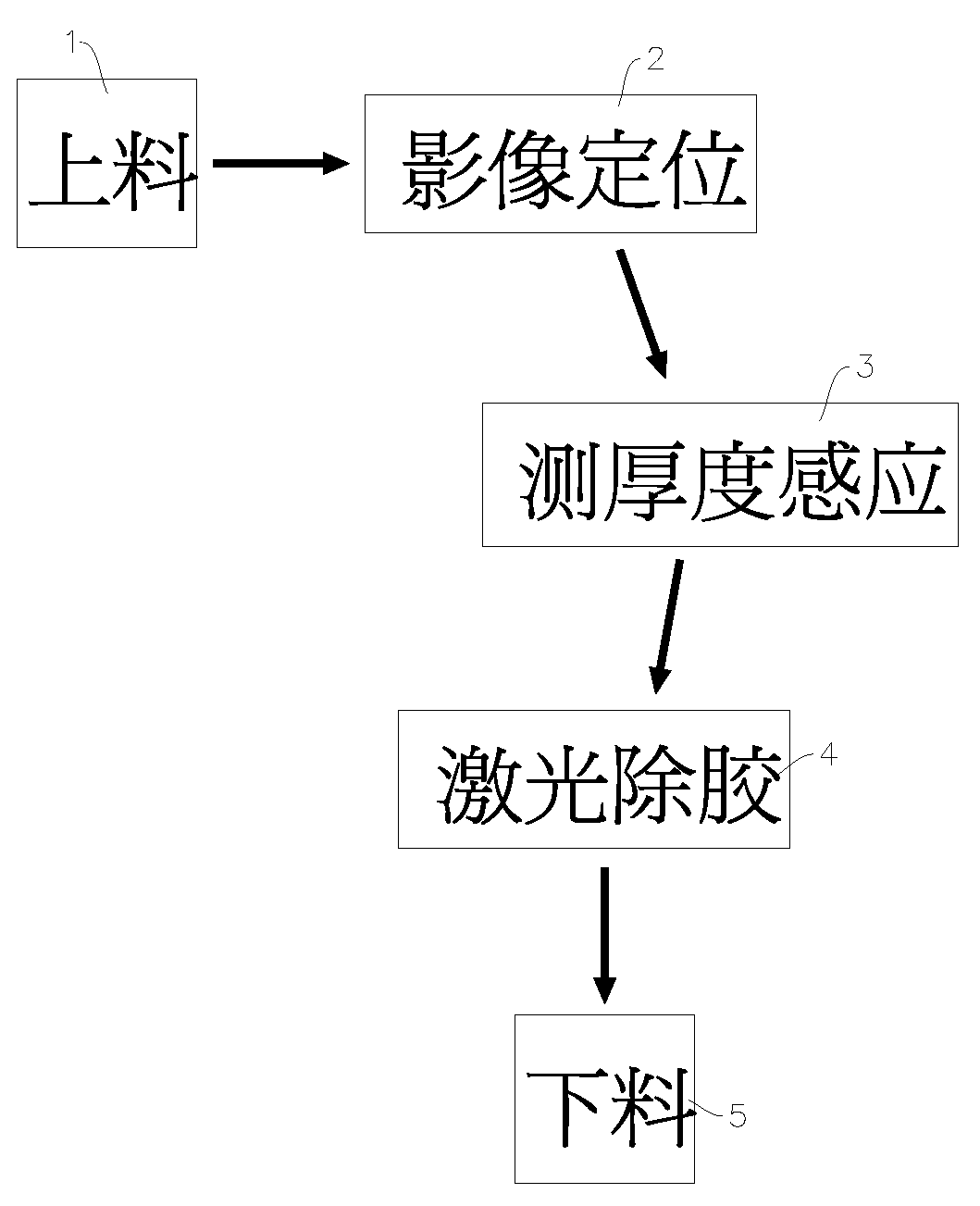

[0046] Please refer to FIG. 2; FIG. 2 is a flow chart of the laser degumming process of the present invention.

[0047] As can be seen from the figure, the laser deglue process of the present invention has the following steps:

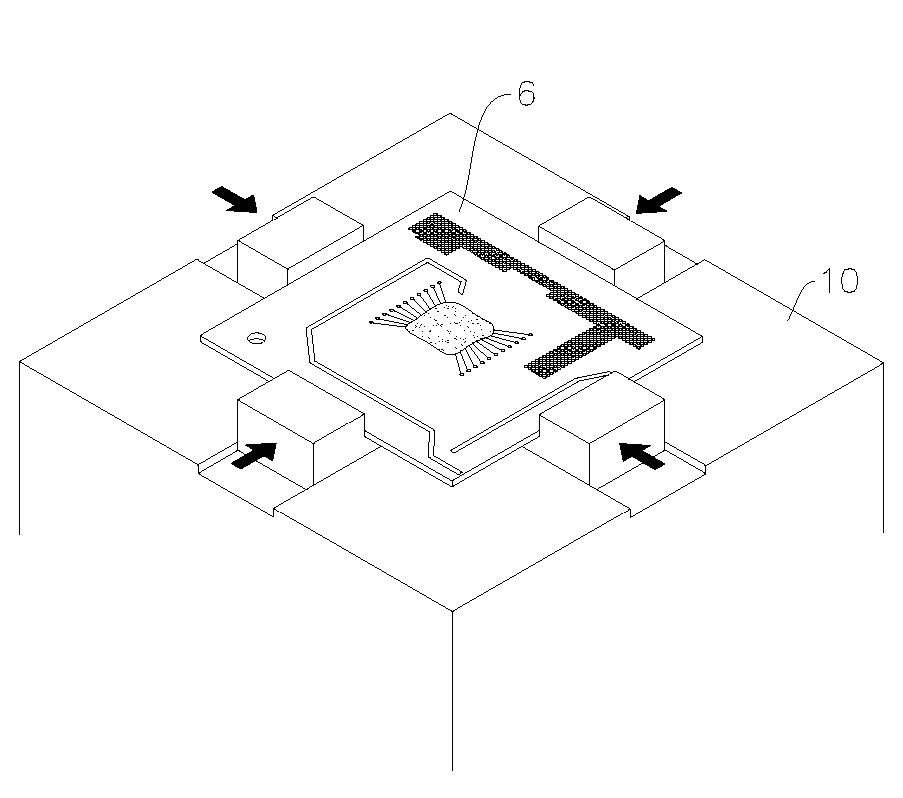

[0048] A. Loading 1: Loading 1 of electronic components on a platform.

[0049] B. Image positioning 2: Use the image positioning device of image positioning 2 to measure and position the volume on the electronic component.

[0050] C. Thickness measurement sensor 3: Use the sensing device of thickness measurement sensor 3 to detect the epoxy resin coating thickness and coating area on the BGA package on the electronic component.

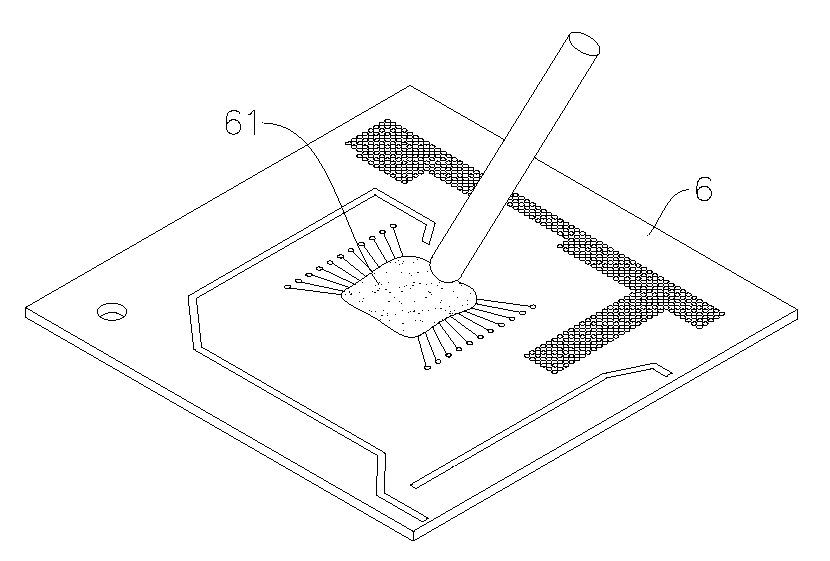

[0051] D. Laser glue r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com