ABC dry powder extinguishing agent

A technology of dry powder fire extinguishing agent and fire extinguishing agent, which is applied in the direction of fire prevention equipment, etc., can solve the problems of low fire extinguishing efficiency, pollution, and low efficiency, and achieve the effects of fast fire extinguishing speed, high fire extinguishing efficiency and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

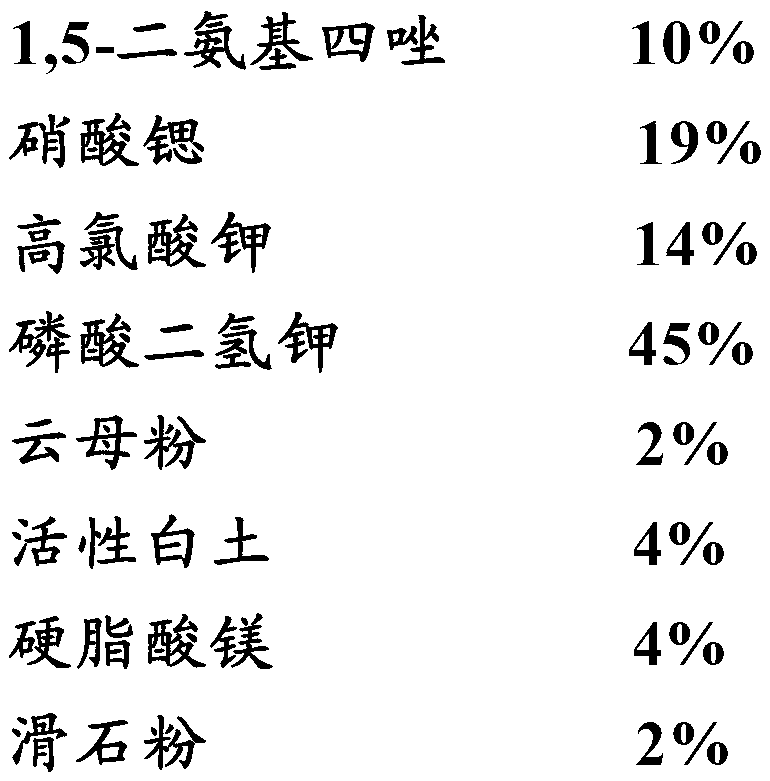

[0065] An ABC dry powder fire extinguishing agent is composed of 1,5-diaminotetrazole, strontium nitrate, potassium perchlorate, potassium dihydrogen phosphate, mica powder, activated clay, magnesium stearate, and talcum powder, wherein the total weight of the fire extinguishing agent is Calculate, the weight percentage of each component is:

[0066]

[0067] Brief description of the preparation process: firstly bake raw materials such as 1,5-diaminotetrazole, strontium nitrate, potassium dihydrogen phosphate, potassium perchlorate and other raw materials with high moisture content, and then send them into an ultrafine pulverizer to grind them into particle sizes (D 50 ) powders smaller than 40 microns. Mica powder, activated clay, magnesium stearate, talcum powder and other auxiliary materials are also pulverized into (D 50 ) powders smaller than 40 microns for use. Add weighed 1,5-diaminotetrazole, strontium nitrate, potassium dihydrogen phosphate, potassium perchlorate...

Embodiment 2

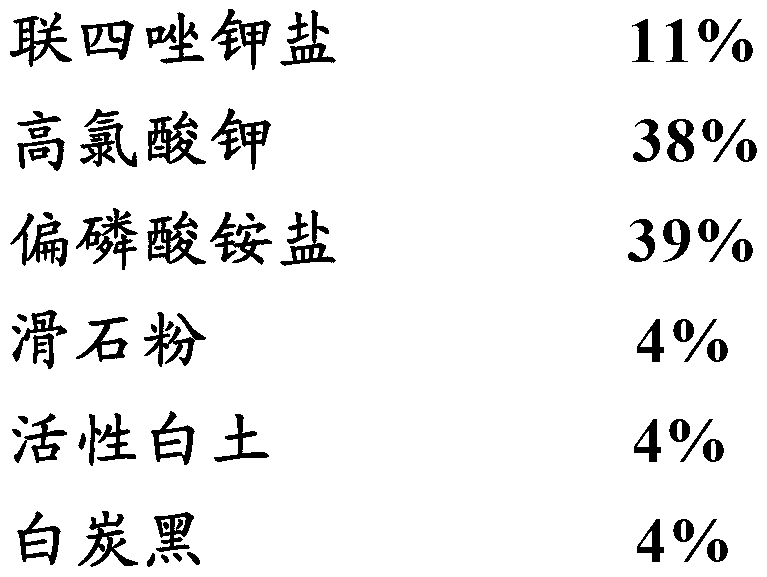

[0069] An ABC dry powder fire extinguishing agent is composed of potassium tetrazolium salt, potassium perchlorate, ammonium metaphosphate, activated clay, talcum powder, and white carbon black, wherein, based on the total weight of the fire extinguishing agent, the weight percentage of each component for:

[0070]

[0071] The dry powder fire extinguishing agent is prepared according to the method described in Example 1, wherein the white carbon black is added together when the talcum powder is added.

Embodiment 3

[0073] An ABC dry powder fire extinguishing agent is composed of azotetrazole sodium salt, lithium nitrate, ammonium metaphosphate, activated clay, talcum powder, white carbon black, and organic silicon oil, wherein, calculated by the total weight of the fire extinguishing agent, the The weight percentage is:

[0074]

[0075]

[0076] The dry powder fire extinguishing agent is prepared according to the method described in Example 2, wherein the silicone oil is mixed with azotetrazolium sodium salt, lithium nitrate, ammonium metaphosphate and activated clay evenly and heated to 50°C with talcum powder Add together with white carbon black, continue stirring and mixing for 10 minutes to discharge, and finally vacuum dry, sieve to remove particles with a size larger than 0.25 mm, inspect, and pack to obtain the ABC dry powder fire extinguishing agent of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com