A preparation method and applications of a lithium battery material with high rate performance

A lithium battery material, high-rate technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reduced electrical conductivity of materials, reduction of high-rate performance of battery negative electrode materials, increase of polarization resistance and mass transfer resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

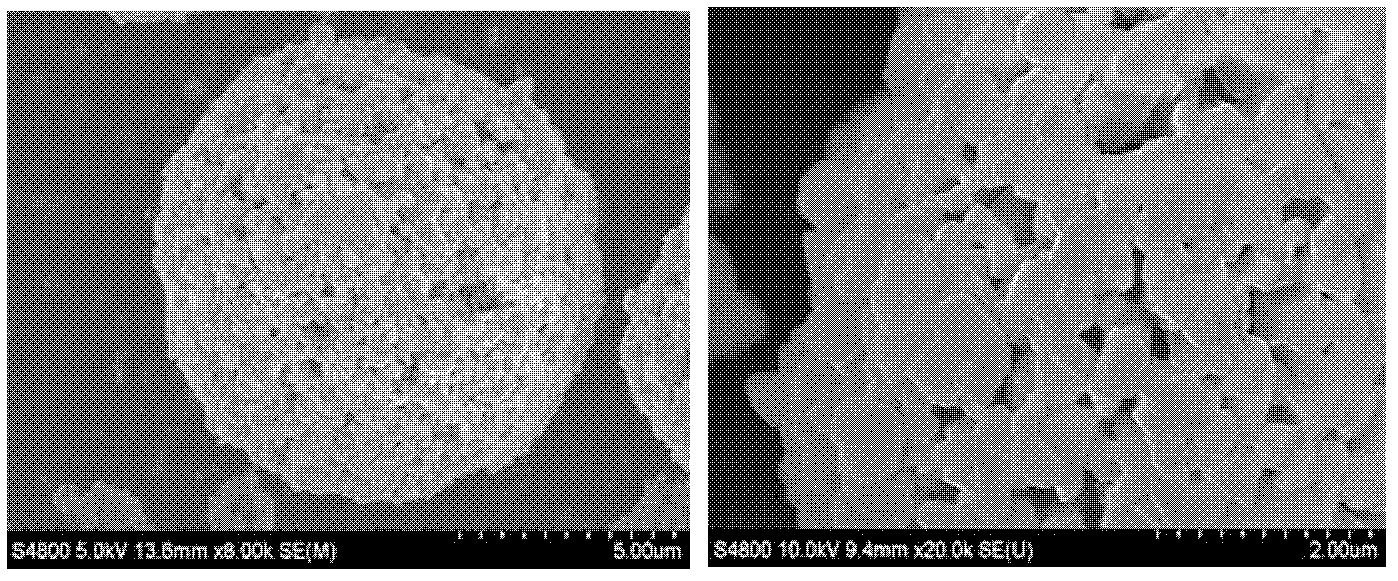

[0030] As mentioned above, the purpose of the present invention is to increase the electrical conductivity, reduce the mass transfer resistance, and enhance the high-rate performance by changing the pore size of the lithium battery material and enhancing the close contact between the small particles inside the spherical particles. For this reason, the present invention provides a kind of lithium battery material preparation method with high rate performance, and described preparation method comprises the following steps:

[0031] The first step is to provide the titanium precursor titanium dioxide;

[0032] In the second step, the titanium precursor titanium dioxide, pore-forming agent and water are uniformly mixed to form a water slurry with a solid content of 10-40% by weight, preferably 15-35% by weight, most preferably 20-30% by weight, and the The ratio of the pore-forming agent in the total solid content is 10-50% by weight, preferably 15-40% by weight, most preferably 1...

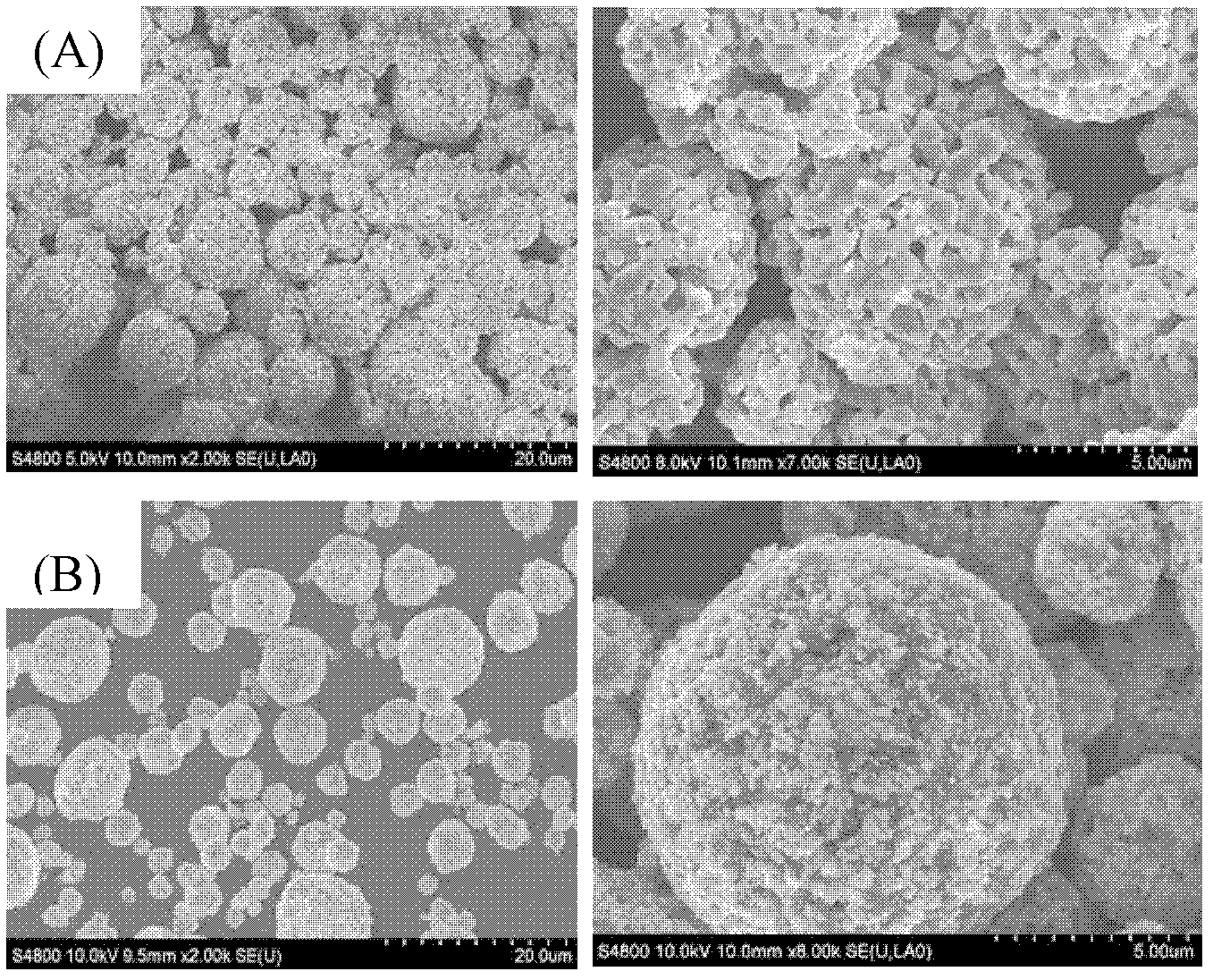

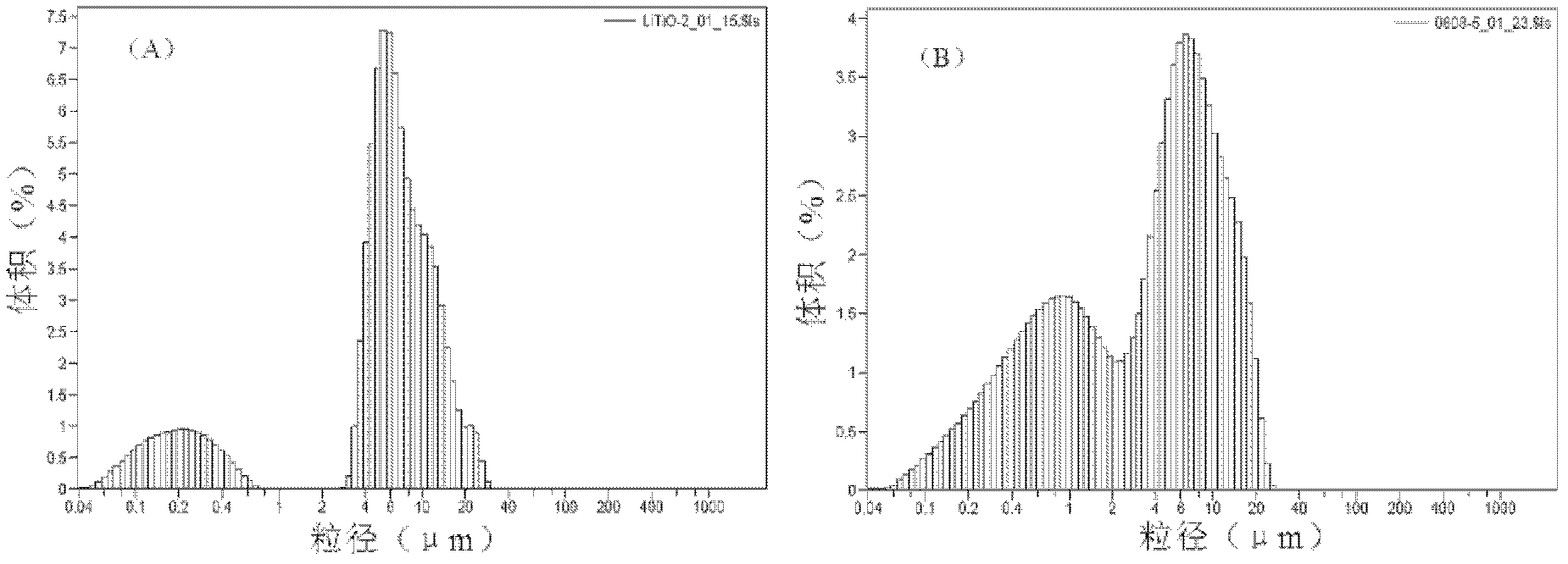

Embodiment 1

[0056] (1) According to the solid content of 30% in the water slurry before spray drying, weigh 54g of titanium dioxide powder (Shanghai Pengbo Titanium Dioxide Co., Ltd., model PG995), 6g of soluble starch, add 200ml of deionized water, 300rpm / min magnetic force Stir for 24 hours, mix well;

[0057] (2) On a spray dryer (Shanghai Yacheng Instrument Equipment Co., Ltd., model YC-015), pump the mixed slurry into the spray chamber at a speed of 50rpm / min, and spray dry it at 200°C under a pressure of 3MPa into spherical particles, cooling;

[0058] (3) After spray-drying powder, in nitrogen (N 2 ) in an atmosphere furnace under the protection of 500°C for 3 hours, and then placed in a muffle furnace for 3 hours at 500°C to obtain spherical mesoporous titanium dioxide powder;

[0059] (4) Weigh 18.6g of the corresponding mesoporous titanium dioxide powder, 6.9g of lithium carbonate, and 4.0g of soluble starch, add them to 100ml of deionized water, and stir magnetically at 300rp...

Embodiment 2

[0077] (1) According to the solid content of 30% in the water slurry before spray drying, weigh 45g of titanium dioxide powder (Shanghai Pengbo Titanium Dioxide Co., Ltd., model PG995), 45g of soluble starch, add 300ml of deionized water, 300rpm / min magnetic force Stir for 24 hours, mix well;

[0078] (2) On a spray dryer (Shanghai Yacheng Instrument Equipment Co., Ltd., model YC-015), pump the mixed slurry into the spray chamber at a speed of 50rpm / min, and spray dry it at 200°C under a pressure of 3MPa into spherical particles, cooling;

[0079] (3) After spray drying, the powder is placed in a muffle furnace and heat-treated at 600°C for 3 hours to obtain spherical mesoporous titanium dioxide powder;

[0080] (4) Weigh 18.6g of the corresponding mesoporous titanium dioxide powder, 6.9g of lithium carbonate, and 4.0g of soluble starch into 100ml of deionized water, and stir magnetically at 300rpm / min at room temperature for 24h to mix;

[0081] (5) Put the mixed slurry in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com