OPC correction method based on photoetching process window

A photolithography process, photolithography technology, applied to the original for photomechanical processing, photoplate process of pattern surface, optics, etc., can solve the difficulty of weight value selection, low reliability of OPC model, and weight value selection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, the detailed description is as follows in conjunction with the illustrated embodiment:

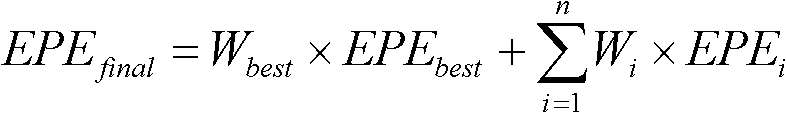

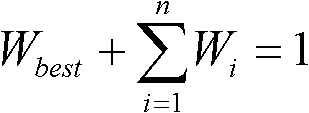

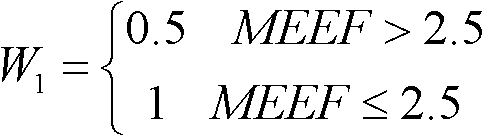

[0016] The OPC correction method based on photolithography process window of the present invention, its objective function EPE final The value of the weight of each lithography model in the layout is not fixed for different graphics in the layout, but is set according to the characteristics of different graphics and the surrounding environment of the graphics. The weight setting method is through a certain functional form W i =f(x 1 , x 2 ,…) to control, where, x i MEEF (Mask Error Enhancement Factor, mask error enhancement factor), I max (maximum light intensity), I min (minimum value of light intensity) or Slope (slope), etc., x can also exist in the function i with x j A product term of .

[0017] Specifically, weights can be set through the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com