Nano coating preparation method and antibiosis nano coating prepared by nano coating

A nano-coating and plasma technology, used in coatings, metal material coating processes, and biocide-containing paints, etc. Antibacterial effect, good antibacterial effect, broad antibacterial spectrum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

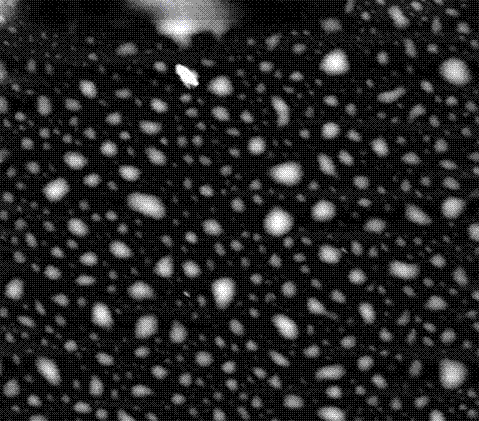

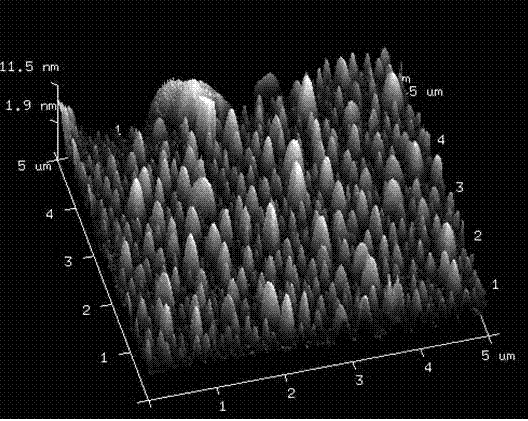

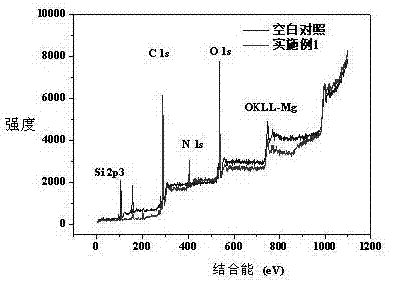

Image

Examples

preparation example Construction

[0039] The purpose of the present invention is to provide a method of using low -temperature plasma polymerization technology to prepare nano -coating, as well as at least one polymer antibacterial nano -coating corresponding to it.The process can obtain the coating of different antibacterial effects, and through the organic monomer plasma, the group and polymer that the conventional aggregation technology can not be obtained or difficult to obtain can be prepared, and the polymer is directly deposited on the base material during the reaction process.And form a reliable covalent key, so that the deposit coating has excellent drug resistance, thermal stability and mechanical properties.A method for preparing a nano -coating of the present invention, including the following steps:

[0040] Pre -processing steps: Put the bases made of the base material into the plasma cavity chamber to draw the vacuum of the plasma cavity chamber, pass into the non -aggregate gas, turn on the electro...

Embodiment 2

[0049] [Example 2] Ethylene amine-acrylic plasma dual-coated antibacterial nano-coating with cellulose non-woven fabric as the base material

[0050] Select and embodiment 1 The same ethylene amine and acrylic hybrid monomer to gather plasma co -concentration, and the base material layer is cellulose non -woven fabric.First of all, pre -processing cellulose non -woven fabric with nitrogen as a non -aggregate gas, nitrogen flow is 30 SCCM, maintaining the vacuum degree ~ 40 PA discharge in the pulse radio -plasma 2 min, the pulse occupation ratio is 40%, discharge discharge, dischargeThe power is 50 W; the Moore ratio of the mixed monomer is different from the embodiment 1, such as 6: 4, or 7: 3, the single mixed gas after gasification is introduced into a plasma body cavity room with a flow of 80 SCCM, maintaining the vacuum of 50Pa, discharge power 50 min is 20 min under the condition, and the ethylene amine-acrylic plasma dual-dual polymer antibacterial nano-coating.

[0051] [E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com