Omnibearing coproduction system and method by utilizing coal grading

An all-round, multi-generation technology, applied in the field of coal chemical industry, can solve problems such as unsatisfactory high-temperature separation of oil and gas, low coal utilization rate, and poor adjustability of multi-generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

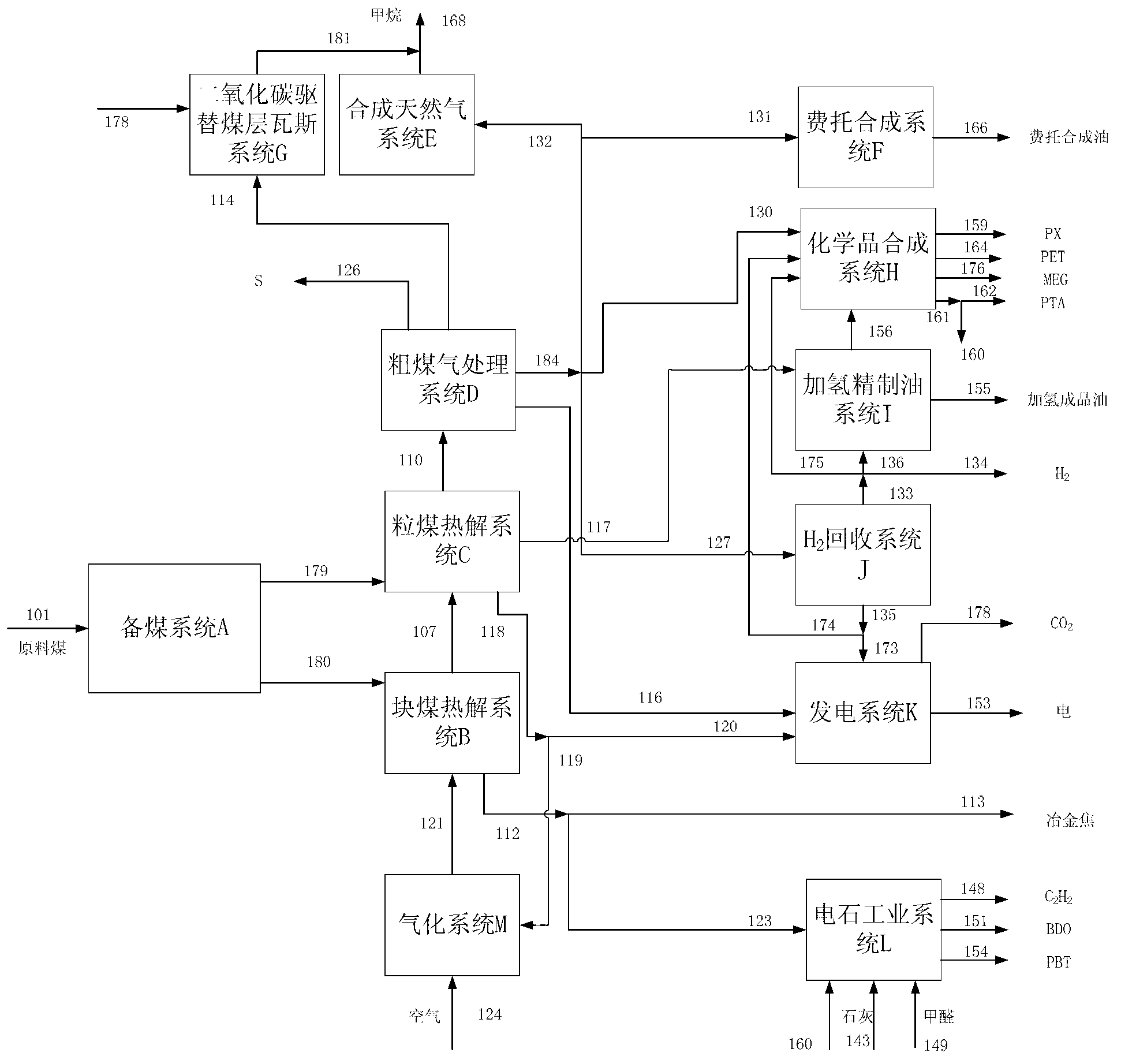

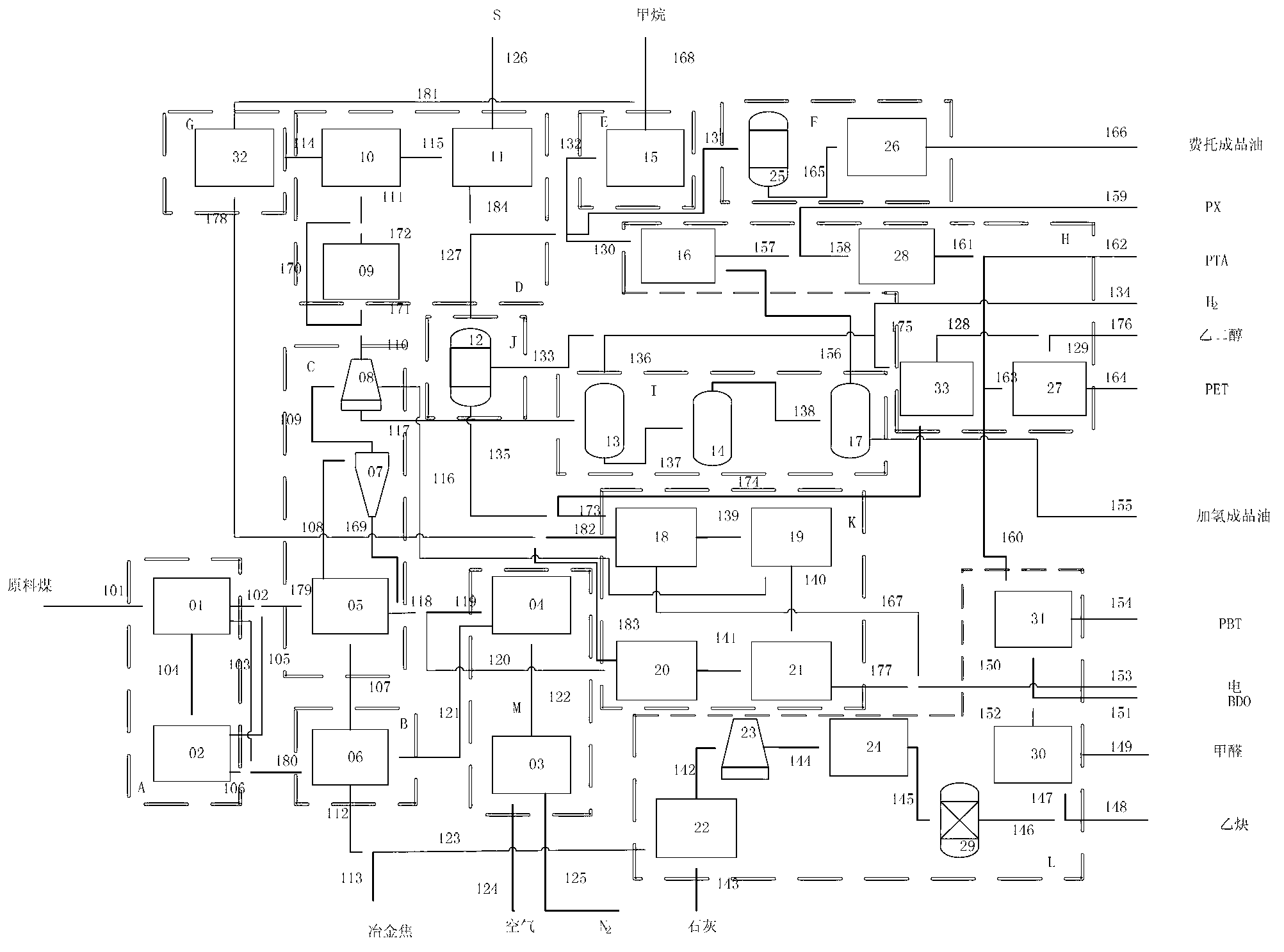

[0026] The overall composition structure of the system of the present invention is as follows: figure 1 Shown:

[0027] Coal preparation system A uses raw coal 101 as raw material, and has two outlets of granular coal 179 and lump coal 180, the outlet of lump coal 180 is connected to the raw material inlet of lump coal pyrolysis system B, and the outlet of granular coal 179 is connected The raw material inlet of system C is connected.

[0028] The heat carrier of the lump coal pyrolysis system B is provided by the gasification gas 121 produced in the gasification system M. The lump coal pyrolysis system B is provided with a lump coal pyrolysis oil gas 107 outlet and a lump coke 112 outlet, and the lump coal pyrolysis oil gas 107 The outlet is connected to the heat carrier inlet of granular coal pyrolysis system C, and the lump coke 112 outlet of lump coal pyrolysis system B is divided into two routes, one is directly output as metallurgical coke 113, and the other is used as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com