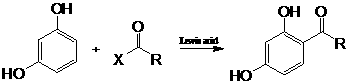

Preparation method for 4-butylresorcinol

A technology of butylresorcinol and butyrylresorcinol, which is applied in the field of preparation of 4-butylresorcinol, can solve the problem of low conversion rate of raw materials or product yield, many by-products, high reaction conditions, etc. problem, achieve the effect of shortening the reaction time, increasing the reaction yield and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049]Under nitrogen protection, put 15g of potassium hydroxide and 22mL of diethylene glycol into the flask, immerse in a preheated 100°C oil bath, stir until the solid dissolves, add 8.0g of 4-butyryl resorcinol, Continue to stir until it is completely dissolved, add hydrazine hydrate dropwise, and the solution turns dark green. After the dropwise addition, heat to reflux for 2 hours, distill out hydrazine hydrate until the internal temperature reaches 190°C, and continue to reflux the residue for 3-4 hours. TLC detects that there is no raw material. Cool the reaction solution, add concentrated hydrochloric acid dropwise to pH 3.0, add ice water and ethyl acetate for extraction, wash the organic phase with a saturated solution of sodium bicarbonate, wash with saline, dry over anhydrous sodium sulfate, and concentrate to obtain a brown-red oily liquid, which is washed by 6.2 g of colorless solid recrystallized from benzene.

[0050]

Embodiment 2

[0052] Under nitrogen protection, put 17g of sodium hydroxide and 22mL of diethylene glycol into the flask, immerse in a preheated 100°C oil bath, stir until the solid dissolves, add 8.0g of 4-butyryl resorcinol, Continue to stir until it is completely dissolved, add hydrazine hydrate dropwise, and the solution turns dark green. After the dropwise addition, heat to reflux for 2 hours, distill out hydrazine hydrate until the internal temperature reaches 190°C, and continue to reflux the residue for 3-4 hours. TLC detects that there is no raw material. Cool the reaction solution, add concentrated hydrochloric acid dropwise to pH 3.0, add ice water and ethyl acetate for extraction, wash the organic phase with a saturated solution of sodium bicarbonate, wash with saline, dry over anhydrous sodium sulfate, and concentrate to obtain a brown-red oily liquid, which is washed by 5.9 g of colorless solid recrystallized from benzene.

[0053]

Embodiment 3

[0055] Under the protection of nitrogen, put 15g of potassium hydroxide and 22mL of triethylene glycol into the flask, immerse in a preheated 100°C oil bath, stir until the solid dissolves, add 8.0g of 4-butyryl resorcinol, continue Stir until completely dissolved, add hydrazine hydrate dropwise, the solution turns dark green, after the dropwise addition, heat to reflux for 2 hours, distill out hydrazine hydrate until the internal temperature reaches 200 0 ℃, the residue continued to reflux for 3-4 hours, TLC detected no raw materials, cooled the reaction solution, added concentrated hydrochloric acid dropwise to pH 3.0, added ice water and ethyl acetate for extraction, and washed the organic phase with saturated sodium bicarbonate solution and brine. Dry over anhydrous sodium sulfate and concentrate to obtain a brownish-red oily liquid, and 6.1 g of a colorless solid recrystallized from benzene.

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com