Fine chemical wastewater treatment and reuse method

A technology for fine chemical wastewater and aerobic treatment, applied in the field of chemical treatment, can solve the problems of high operating cost of oxidation process, poor biodegradability of wastewater, and many biodegradable substances, and achieve good economic and environmental benefits, maintainable Strong performance and good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The invention provides a fine chemical wastewater treatment and reuse method based on membrane bioreactor (MBR)-reverse osmosis (RO) combined technology, which mainly includes the following processing steps:

[0066] (1) The fine chemical wastewater is treated through oil separation, air flotation, coagulation and sedimentation; the oil separation tank in this embodiment mainly includes functional areas for dosing and demulsification, and the air flotation functional area can also be included in the separation In the oil pool; the coagulation sedimentation tank is divided into three functional areas: mixing, reaction and sedimentation. The coagulants PAC and PAM are added in the mixing area. After coagulation and sedimentation, most of the insoluble pollutants and a small amount of soluble matter in the wastewater are eliminated remove.

[0067] (2) The effluent of coagulation sedimentation enters the hydrolysis treatment system. In the hydrolysis treatment system, ther...

Embodiment 2

[0071] In this embodiment, the same operation steps as in Embodiment 1 are adopted, that is, a method for treating and reusing fine chemical wastewater, comprising the following steps:

[0072] (1) Fine chemical wastewater is treated through oil separation, air flotation, coagulation and sedimentation;

[0073] (2) The effluent of coagulation sedimentation enters the hydrolysis treatment system. In the hydrolysis treatment system, there are anaerobic microbial extracellular enzymes. Biodegradation of organic matter, reducing the organic load while improving the biodegradability of wastewater;

[0074] (3) The effluent of the hydrolysis treatment system enters the aerobic treatment system, and there are aerobic microorganisms in the aerobic treatment system, which are used to decompose organic matter into end products;

[0075] The waste water from the aerobic treatment system in step (3) enters the MBR system for further aerobic treatment, and at the same time separates the m...

Embodiment 3

[0080] Adopt the same operating procedure of embodiment 1 in the present embodiment, and with the material identical with embodiment 1, process through following steps:

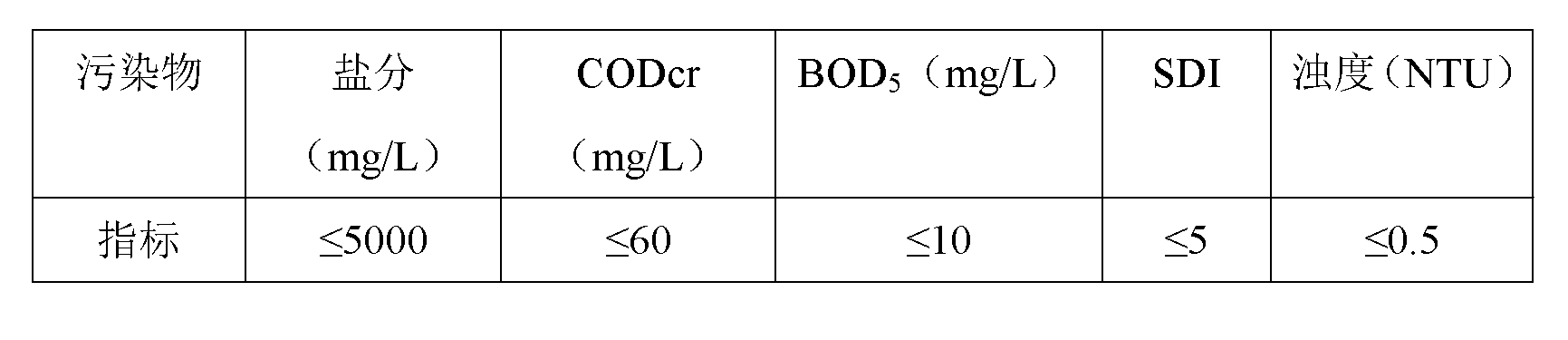

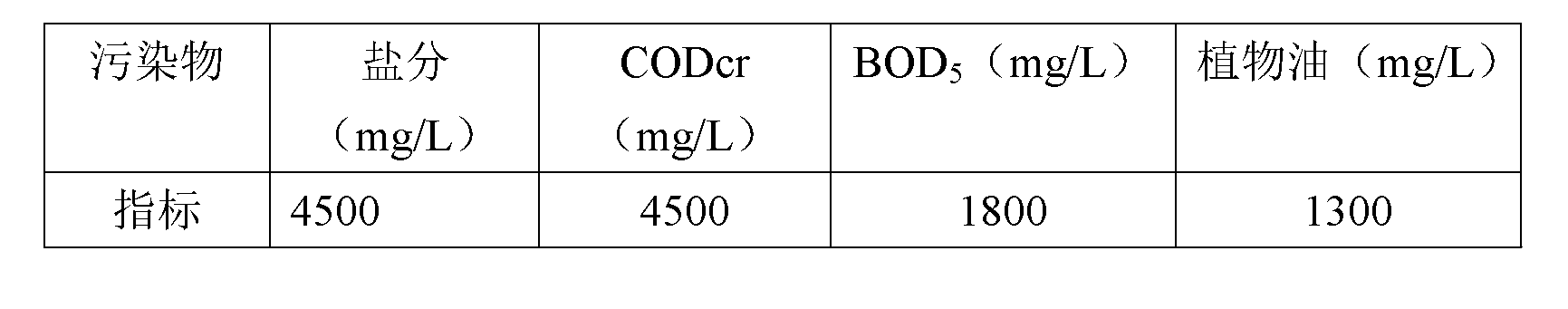

[0081] The concrete index of the pollutant that adopts in the present embodiment is as follows:

[0082]

[0083] (1) Fine chemical wastewater is treated through oil separation, air flotation, coagulation and sedimentation; oil, suspended solids and soluble substances in the adsorption state are removed from the wastewater, reducing the load on the subsequent treatment system;

[0084] (2) The effluent of coagulation sedimentation enters the hydrolysis treatment system. In the hydrolysis treatment system, there are anaerobic microbial extracellular enzymes. Biodegradation of organic matter, reducing the organic load while improving the biodegradability of wastewater;

[0085] (3) The effluent of the hydrolysis treatment system enters the aerobic treatment system. There are aerobic microorganisms in the ae...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com