Cassava rice and processing method thereof

A cassava and raw flour technology, applied in application, food preparation, food science and other directions, can solve the problems of high viscosity of cassava starch, low nutrient content, limited edible range, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

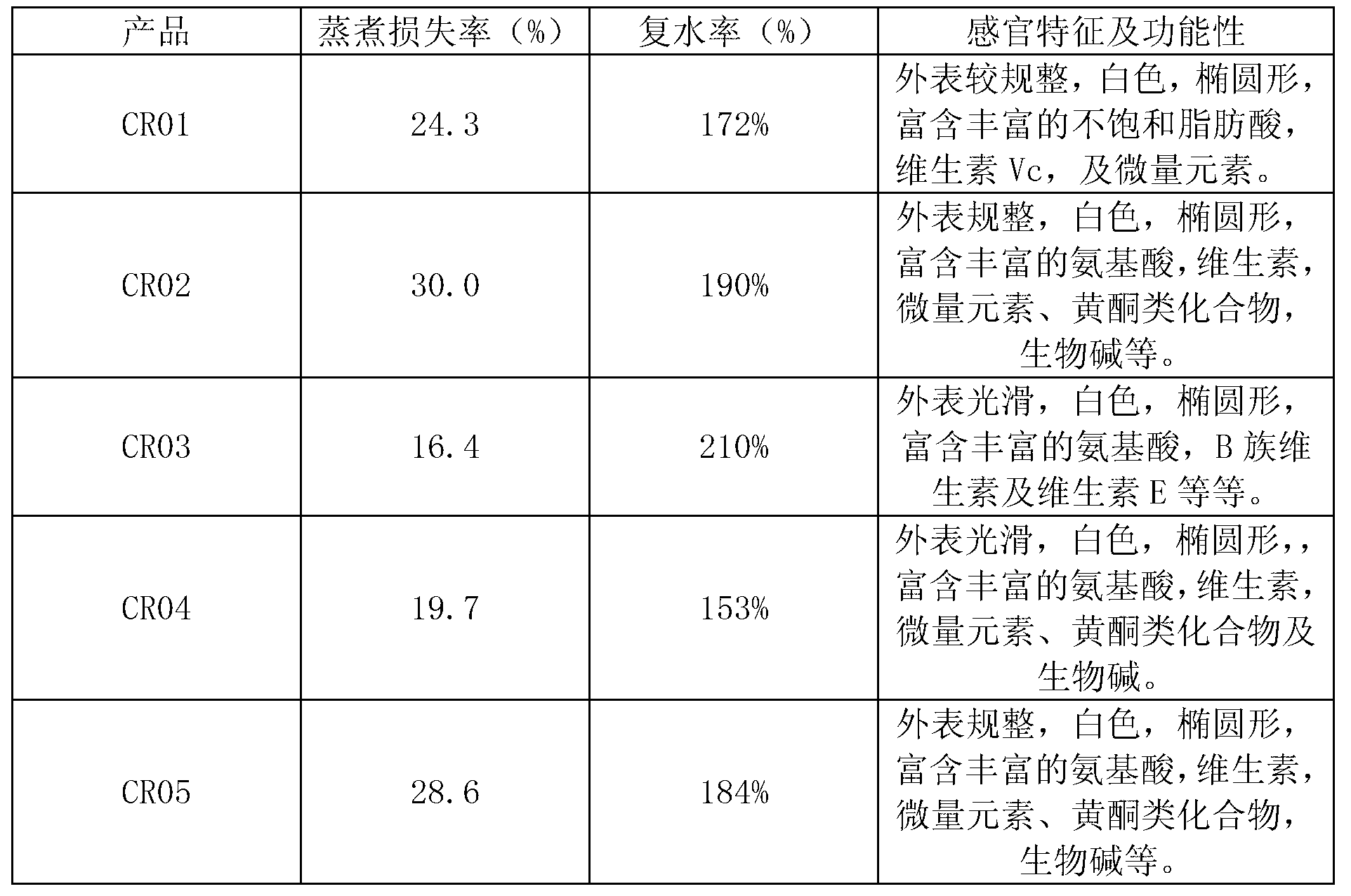

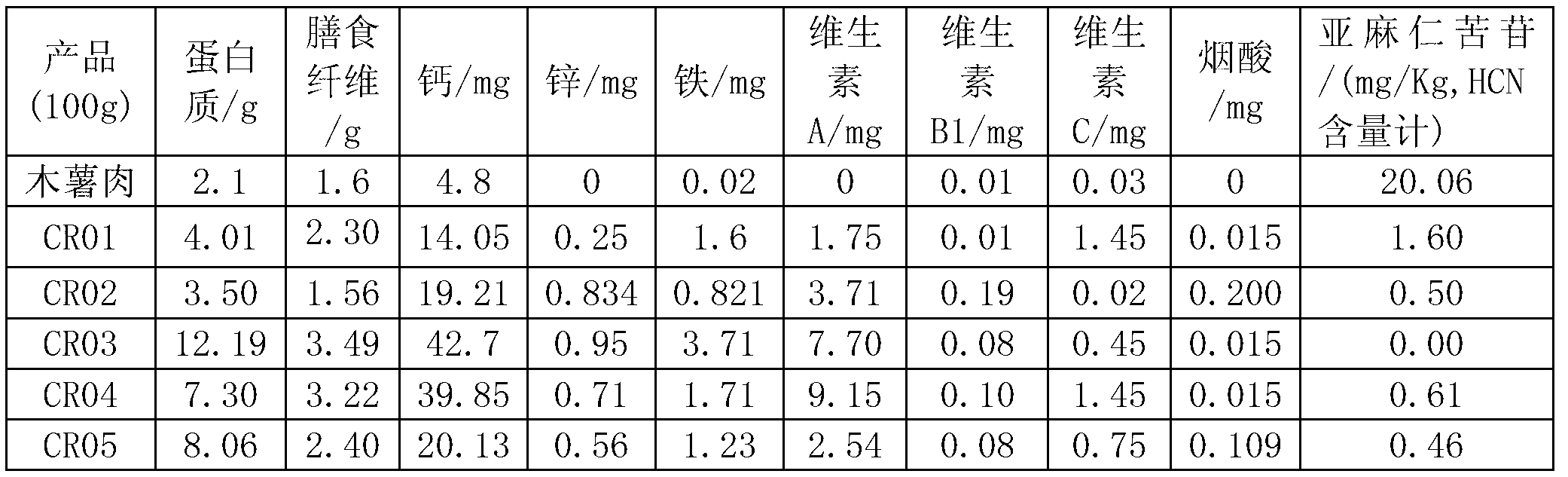

Examples

Embodiment 1

[0030] 1) Mix cassava starch, crushed rice flour, chestnut powder, and yam powder according to the weight percentage ratio of 60%, 30%, 5%, and 5%, and pass through 40 meshes to obtain the original powder;

[0031] 2) Dissolve 0.005% gelatin, 1.5% edible alcohol and 0.5% edible oil in warm water, and then add them together to the original powder, stir evenly, and finally adjust the water content of the original powder according to the weight percentage 25%;

[0032] 3) Put the prepared raw powder into the single-screw extruder, adjust the screw speed of the single-screw extrusion to 100r / min, the cutter speed to 500r / min, the barrel temperature of the first stage is 50°C, and the second stage is 60°C, 80°C for the third stage, 90°C for the fourth stage, and 80°C for the fifth stage to obtain a cassava rice with a similar shape to rice;

[0033] 4) The cassava rice prepared in step 3) is broken up and sieved under the action of a vibrating sieve, and then dried in a hot air dr...

Embodiment 2

[0038] 1) Mix cassava starch, corn starch, soybean powder, beef powder and banana powder according to the weight percentage ratio of 60%, 20%, 10%, 5%, and 5%, and pass through 40 meshes to obtain the original powder;

[0039] 2) Dissolve 0.015% gelatin, 1.5% edible alcohol and 0.5% edible oil in warm water, and then add them together to the original powder, stir evenly, and finally adjust the water content of the original powder according to the weight percentage 25%;

[0040] 3) Put the prepared raw powder into the single-screw extruder, adjust the screw speed of the single-screw extrusion to 100r / min, the cutter speed to 500r / min, the barrel temperature of the first stage is 50°C, and the second stage is 70°C, 85°C for the third stage, 100°C for the fourth stage, and 90°C for the fifth stage to obtain a cassava rice with a similar shape to rice;

[0041] 4) The cassava rice prepared in step 3) is broken up and sieved under the action of a vibrating sieve, and then dried in...

Embodiment 3

[0046] 1) Mix cassava starch, crushed rice flour, soybean powder, yam powder, and banana powder according to the weight percentage ratio of 30%, 40%, 20%, 5%, and 5%, and pass through 40 meshes to obtain the original powder;

[0047] 2) Dissolve 0.02% gelatin, 0.5% edible alcohol and 0.5% edible oil in warm water, and then add them together to the original powder, stir evenly, and finally adjust the water content of the original powder according to the weight percentage 20%;

[0048] 3) Put the prepared raw powder into the single-screw extruder, adjust the screw speed of the single-screw extrusion to 100r / min, the cutter speed to 500r / min, the barrel temperature of the first stage is 60°C, and the second stage is 80°C, 100°C for the third stage, 120°C for the fourth stage, and 90°C for the fifth stage to obtain a cassava rice with a similar shape to rice;

[0049] 4) The cassava rice prepared in step 3) is broken up and sieved under the action of a vibrating sieve, and then dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com