Organic EL device

An organic and relative configuration technology, applied in identification devices, lighting devices, organic semiconductor devices, etc., can solve the problems of long manufacturing time and complexity, and achieve the effect of difficult gas barrier properties and high gas barrier properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example A1

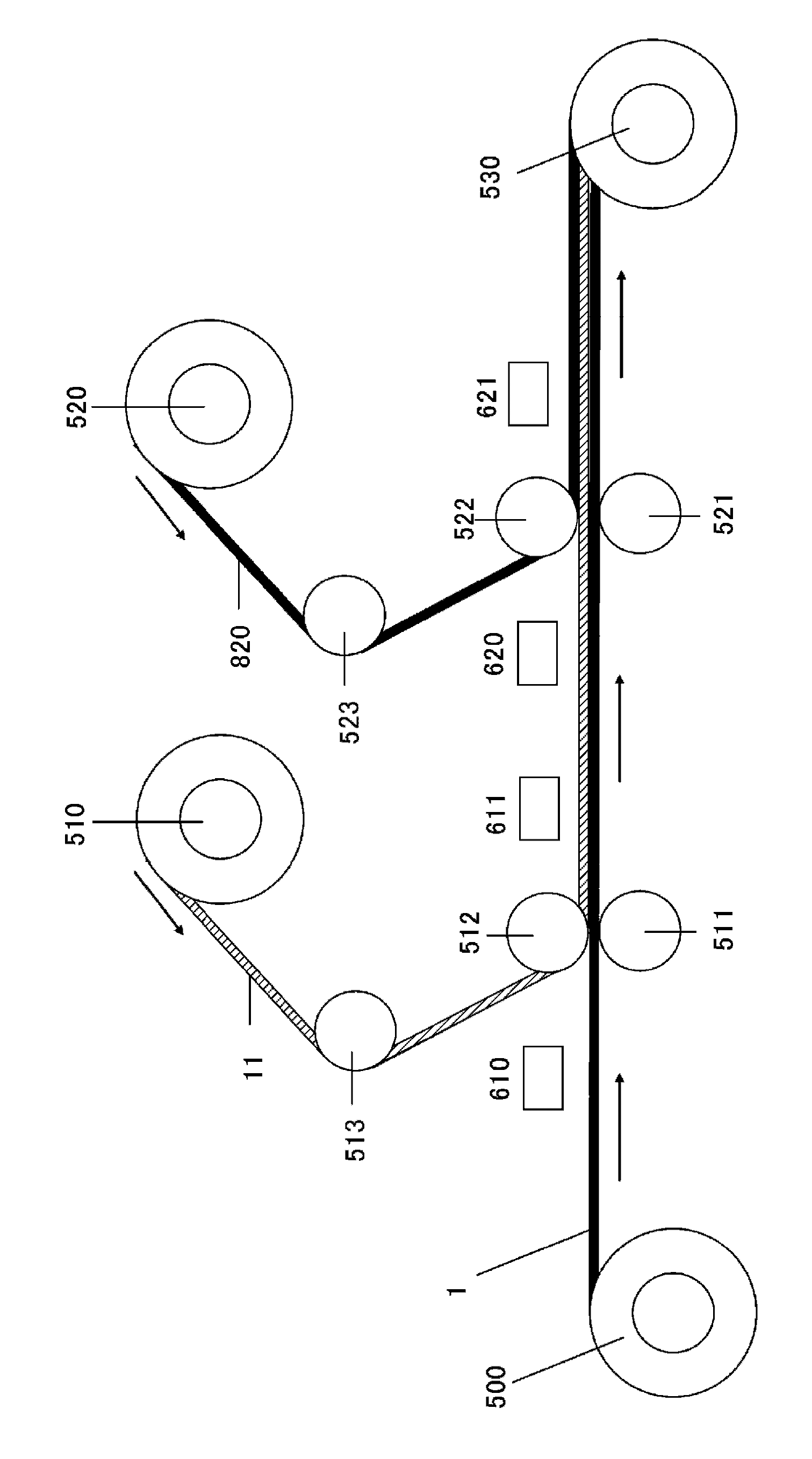

[0217] Use the aforementioned Figure 4 The manufacturing device shown was used to manufacture the second film. That is, a biaxially stretched polyethylene naphthalate film (PEN film, thickness: 100 μm, width: 350 mm, manufactured by Teijin Du Pont film Co., Ltd., trade name "TEONEX Q65FA") was used as the substrate (base Material 6), install it on the delivery roller 701. Then, while a magnetic field is applied between the film forming roller 31 and the film forming roller 32, electric power is supplied to the film forming roller 31 and the film forming roller 32, respectively, to discharge between the film forming roller 31 and the film forming roller 32 to generate plasma. Supply the film-forming gas (mixed gas of hexamethyldisiloxane (HMDSO) as a raw material gas and oxygen (also functioning as a discharge gas) as a reaction gas) to the formed discharge area, and proceed under the following conditions The thin film is formed by the plasma CVD method to obtain a second film...

reference example A2

[0236] The second film having a gas barrier layer with a thickness of 0.3 μm obtained in Reference Example A1 was mounted as the base material 6 on the delivery roller 701, and the gas barrier layer was newly formed on the surface of the gas barrier layer. Except for this, it carried out similarly to the reference example A1, and obtained the 2nd film (A). The thickness of the gas barrier layer on the substrate (PEN film) in the obtained second film (A) was 0.6 μm.

[0237] The obtained second film (A) is mounted on the delivery roller 701 as the base material 6, and the gas barrier layer is newly formed on the surface of the gas barrier layer. Except for this, it carried out similarly to Reference Example A1, and obtained the 2nd film (B).

[0238] The thickness of the gas barrier layer in the obtained second film (B) was 0.9 μm. The water vapor transmittance of the obtained second film (B) was 6.9×10 under the conditions of a temperature of 40°C, a humidity of 0% RH on the low ...

reference example A3

[0242] A second film was obtained in the same manner as in Reference Example A1 except that the supply amount of the source gas was 100 sccm.

[0243] The thickness of the gas barrier layer in the obtained second film was 0.6 μm. The water vapor transmittance of the obtained second film was 3.2×10 under the conditions of a temperature of 40°C, a humidity of 0%RH on the low humidity side, and a humidity of 90%RH on the high humidity side. -4 g / (m 2 ·Day), a value below the detection limit under the conditions of a temperature of 40°C, a humidity of 10% RH on the low humidity side, and a humidity of 100% RH on the high humidity side. Furthermore, the water vapor transmittance of the second film under the conditions of a temperature of 40°C, a humidity of 10% RH on the low humidity side, and a humidity of 100% RH on the high humidity side after bending the second film under the condition of a radius of curvature of 8 mm At a value below the detection limit, it was confirmed that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com