Coating technology of lithium cobalt oxide

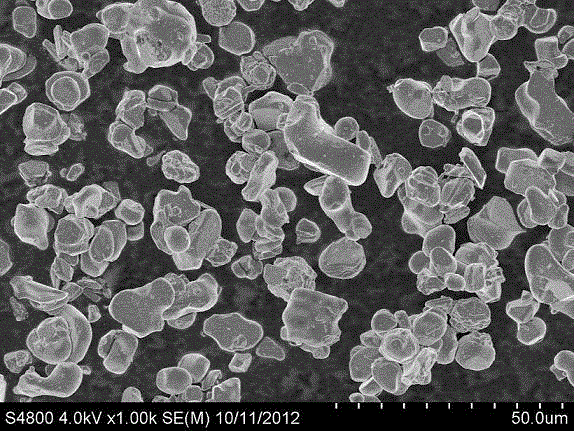

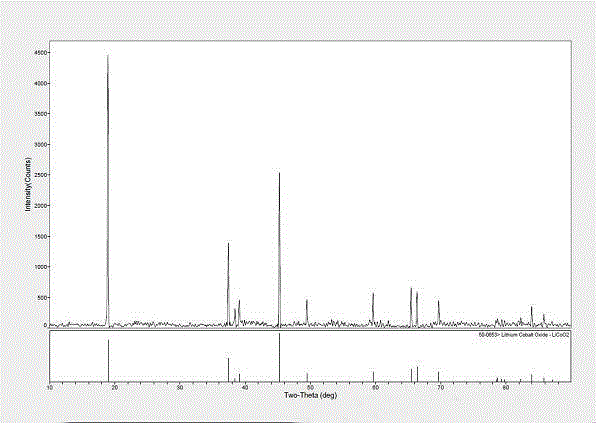

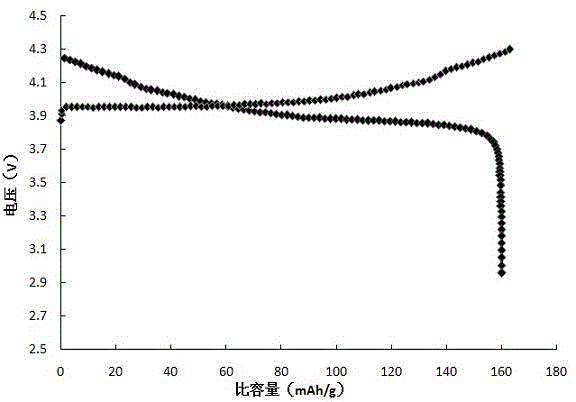

A lithium cobalt oxide coating technology, applied in cobalt compounds, electrode manufacturing, inorganic chemistry, etc., can solve the problems affecting the electrical performance and cycle performance of positive electrode materials, the excessive growth of active material grains, and the uneven particle size of active materials, etc. problems, to achieve the effects of inhibiting excessive growth of grains, improving the uniformity of coating, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Weigh 98g lithium cobaltate (M 钴酸锂 : 98 g / mol), based on the molar weight of lithium cobaltate (1mol), the total molar weight of metal ion compounds is 0.5% of the molar weight of lithium cobalt oxide, and the total molar weight of water-soluble organic matter is 50% of the molar weight of lithium cobalt oxide % of the ratio of metal ion compounds and water-soluble organic matter, wherein the metal ion compound is magnesium oxide (M 氧化镁 : 40 g / mol), the water-soluble organic matter is glucose (M 葡萄糖 : 180 g / mol), and weighed 0.2 g of magnesium oxide and 90 g of glucose.

[0043] (2) After mixing magnesium oxide and glucose evenly, add water with 10% (9 g) of glucose mass, and ball mill at 100 rpm for 5 hours to obtain a primary slurry.

[0044] (3) Lithium cobaltate and 30% (27 g) water of glucose mass were added to the primary slurry, and ball milled at a speed of 50 rpm for 12 hours to obtain a secondary slurry.

[0045] (4) Dry the secondary slurry, the drying...

Embodiment 2

[0060] (1) Weigh 98g lithium cobaltate (M 钴酸锂 : 98 g / mol), based on the molar weight of lithium cobaltate (1mol), the total molar weight of metal ion compounds is 1% of the molar weight of lithium cobalt oxide, and the total molar weight of water-soluble organic matter is 60% of the molar weight of lithium cobalt oxide % ratio to measure metal ion compounds and water-soluble organic compounds, wherein the metal ion compounds are aluminum oxide and magnesium oxide (M 氧化铝 : 102 g / mol, M 氧化镁 : 40 g / mol), aluminum oxide and magnesium oxide are 0.005 mol each, water-soluble organic matter is oxalic acid and citric acid (M 草酸 : 90 g / mol, M 柠檬酸 : 192 g / mol), oxalic acid and citric acid were 0.3 mol each, and 0.51 g of aluminum oxide, 0.2 g of magnesium oxide, 27 g of oxalic acid, and 57.6 g of citric acid were weighed.

[0061] (2) After mixing alumina, magnesium oxide, oxalic acid and citric acid evenly, add water with 15% (12.69 g) of the total mass of oxalic acid and citric aci...

Embodiment 3

[0070] (1) Weigh 98g lithium cobaltate (M 钴酸锂 : 98 g / mol), based on the molar weight of lithium cobaltate (1mol), the total molar weight of metal ion compounds is 2% of the molar weight of lithium cobalt oxide, and the total molar weight of water-soluble organic matter is 70% of the molar weight of lithium cobalt oxide % ratio of metal ion compounds and water-soluble organic compounds, wherein the metal ion compounds are aluminum oxide, magnesium oxide and alum (M 氧化铝 : 102 g / mol, M 氧化镁 : 40 g / mol, M 明矾 : 474 g / mol), alumina and magnesium oxide are 0.005mol each, alum is 0.01mol, water-soluble organic matter is oxalic acid, glucose and acrylic acid (M 草酸 : 90 g / mol, M 葡萄糖 : 180 g / mol, M 丙烯酸 : 72 g / mol), 0.3 mol of oxalic acid and glucose, 0.1 mol of acrylic acid, 0.51 g of aluminum oxide, 0.2 g of magnesium oxide, 4.74 g of alum, 27 g of oxalic acid, 54 g of glucose, and 7.2 g of acrylic acid.

[0071] (2) After mixing alumina, magnesium oxide, alum, oxalic acid, glucose,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com