Movable cable of resistance to drag and scraping prevention and extrusion forming mould device thereof

An extrusion molding and mold technology, applied in the field of mobile cables and their production molds, can solve the problems of easy dragging and scratching, poor safety, and short service life of mobile cables, and achieves improved longitudinal tensile capacity, low cost, and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

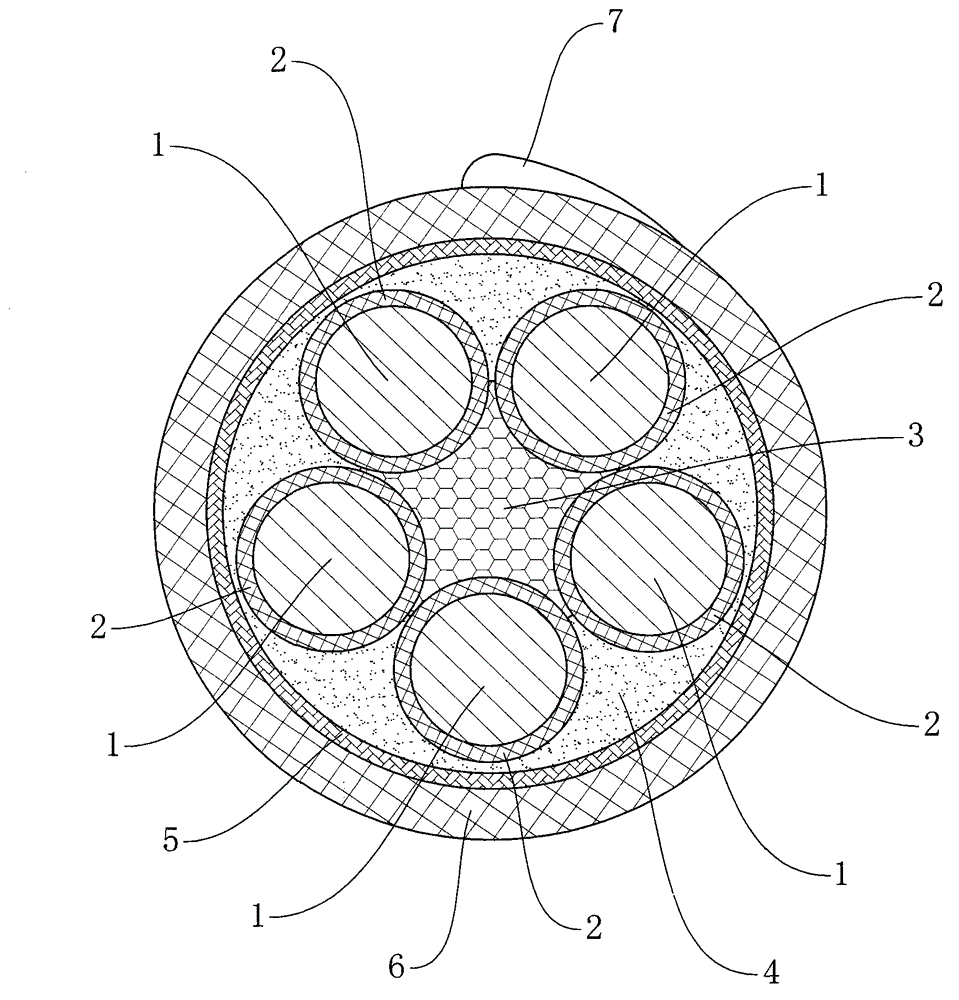

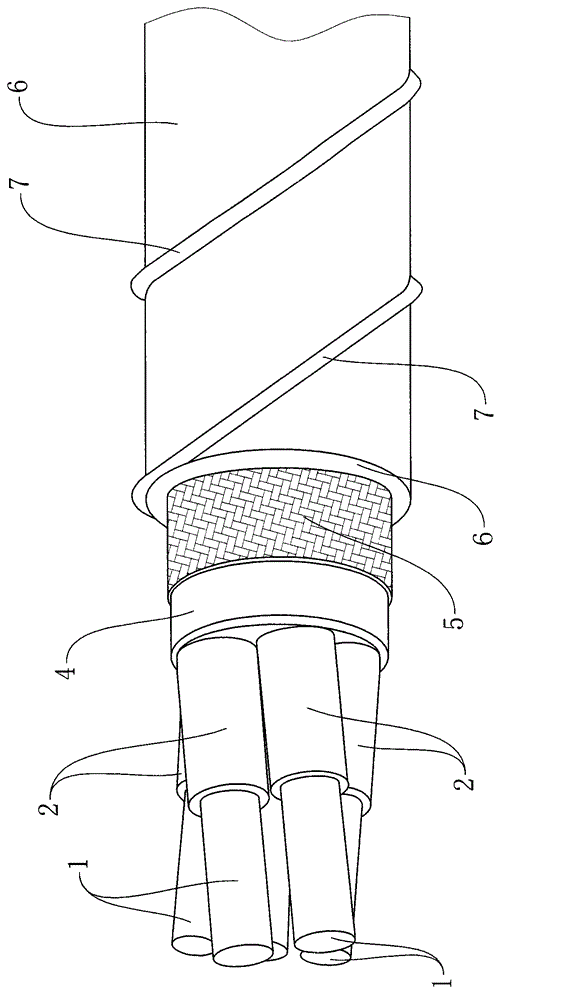

[0018] like figure 1 , figure 2 As shown, a drag-resistant and scratch-resistant mobile cable according to the present invention includes several strands of soft copper conductors 1, insulating coating layers 2, filling ropes 3, rubber and plastic inner lining layers 4, and aramid braided reinforcement layers 5. Elastic and soft outer sheath layer 6. Wear-resistant rubber and plastic ribs 7, wherein the number of strands of the soft copper conductor 1 can be set according to the model specification of the entire mobile cable, without specific restrictions, and figure 1 and figure 2 The scheme shown in is an example structure with five soft copper conductors. The insulating coating layer 2 is coated on each strand of soft copper conductor 1, and the filling rope 3 is arranged in the hollow gap surrounded by the insulating coating layer 2 of each strand of soft copper conductor 1. The filling rope 3 It can not only enhance the longitudinal tensile capacity of the cable, but...

Embodiment 2

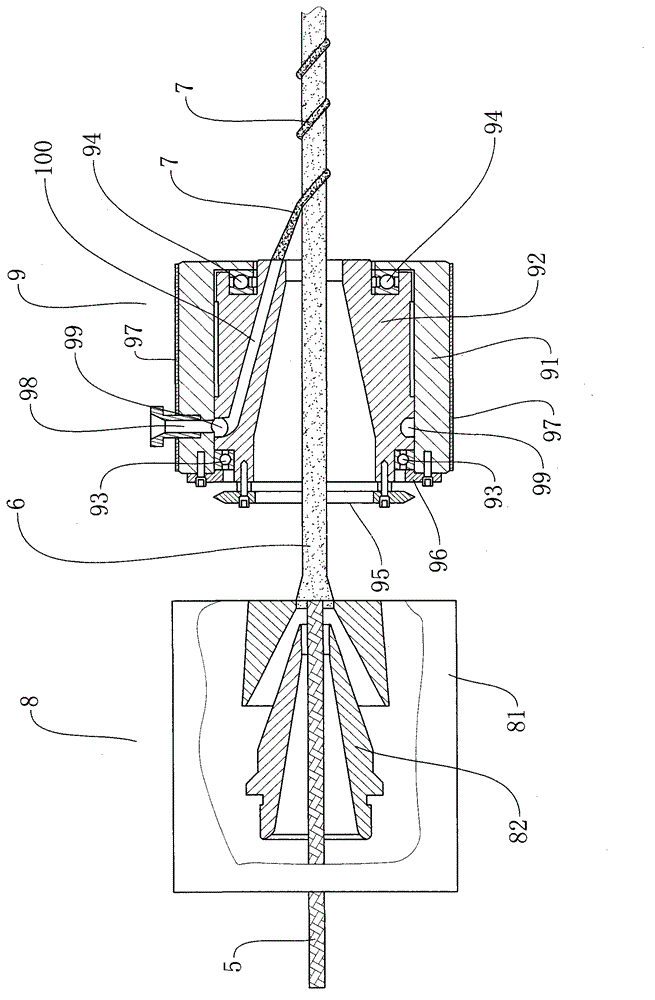

[0020] like image 3 Shown, a kind of extruding molding die device that makes the elastic soft outer sheath layer and wear-resistant rubber and plastic rib of above-mentioned anti-dragging anti-scratch mobile cable, it comprises the extrusion molding of elastic soft outer sheath layer 6 Mold 9 after extrusion molding of front mold 8 and wear-resistant rubber and plastic rib 7, wherein

[0021] The pre-extrusion mold 8 is composed of a female mold 81 and a male mold 82. The pre-extrusion mold 8 is basically the same as a general cable rubber extrusion mold, so it will not be described in detail. In this embodiment, the pre-extrusion mold 8 is introduced together for description, mainly because in practice, the pre-extrusion mold 8 and the extrusion mold 9 work in an assembly line. are interrelated.

[0022] like image 3 As shown, the mold 9 after extrusion molding includes a mold base 91, an inner mold 92, a front bearing 93, a rear bearing 94, a ratchet 95, a gland 96 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com