Device and method for measuring toughness damage evolution in process of metal uniaxial tension

A technology of unidirectional stretching and damage evolution, applied in the direction of measuring devices, strength characteristics, instruments, etc., to achieve the effects of easy construction, expanded application range, and reduced errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Material: SPCC (Baosteel)

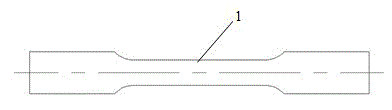

[0043] Tensile sample preparation: According to the ASTM standard small sample, it is prepared by wire cutting, and the geometric dimensions are as follows: figure 2 shown.

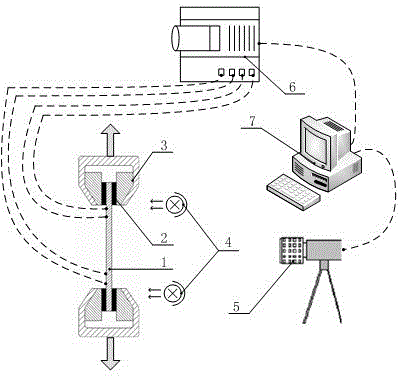

[0044] Test platform construction: in figure 1 In the process, random free speckle is sprayed on the surface of the prepared tensile sample 1, and the insulating plate 2 is glued on the sample clamping part by superglue, and then the tensile sample is clamped by the clamp 3 of the tensile testing machine. A light source 4 is placed on or beside the tensile sample 1, and a camera 5 is fixed on a tripod at a certain distance from the front to ensure that the lens of the camera is perpendicular to the surface of the tensile sample. The four lead wires of the DC low resistance tester 6 are respectively connected to the straight arm part of the tensile sample 1. It should be noted that two of the four lead wires are for direct current, and the other two are for testing v...

Embodiment 2

[0048] Material: SUS304 (Baosteel)

[0049] Sample preparation: according to the ASTM standard small sample, prepared by wire cutting, the geometric dimensions are as follows figure 2 shown.

[0050] Test platform construction: consistent with the steps in Example 1.

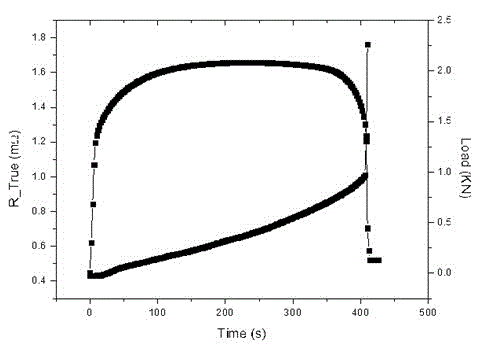

[0051] Test data processing: the steps and process of data processing are the same as those in Example 1. The change of load and resistance during the stretching process of SUS304 tensile sample is as follows: Figure 9 shown. The full-field strain distribution of a certain load step in the necking stage of the tensile specimen in the stretching process is as follows: Figure 10 (side) shown. Also process corresponding data according to embodiment 1, can obtain the relation between the strain of the maximum plastic strain position in the gauge length of the tensile sample and the electric resistance as follows Figure 11 shown. The change of damage of each point with the increase of plastic strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com