Antibacterial and anti-ultraviolet chinlon 6 colored elastic yarn and production method thereof

A technology of anti-ultraviolet and production methods, applied in the direction of rayon manufacturing, single-component polyamide rayon, fiber chemical characteristics, etc., can solve the problem of non-antibacterial and anti-ultraviolet properties, and nylon fabrics only have antibacterial properties and other problems, to achieve the effect of reducing dyeing process, good anti-dyeing, anti-bacterial and anti-ultraviolet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

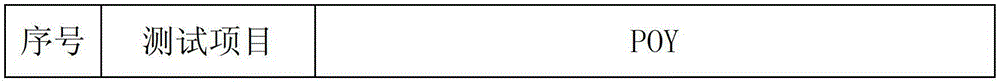

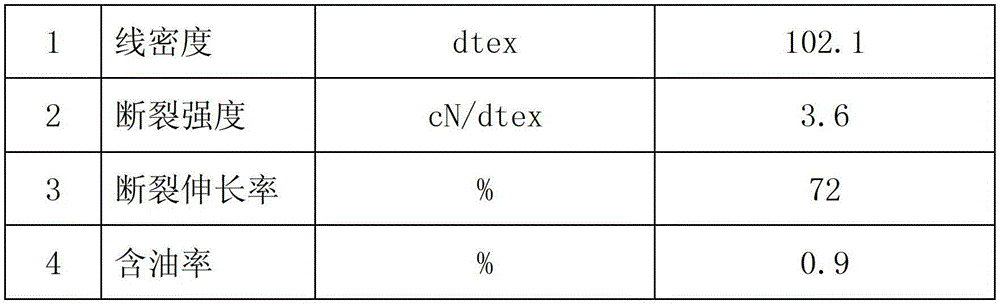

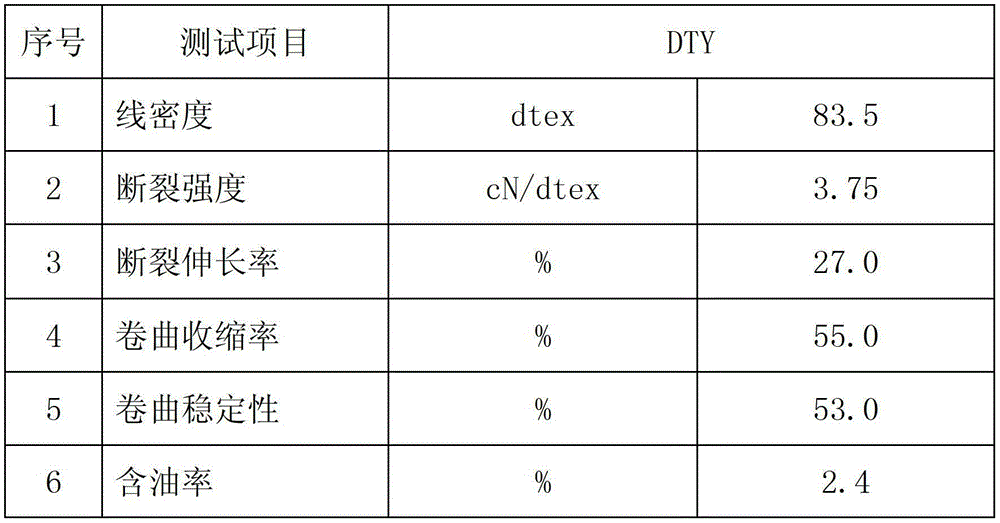

[0023] The antibacterial and anti-ultraviolet nylon 6 colored elastic yarn described in this embodiment is obtained by heating, stretching, false twisting, oiling and winding by nylon 6 POY filament, and it is characterized in that the raw material of said nylon 6 POY is made of Nylon 6 slices, modified antibacterial and anti-ultraviolet dual-functional nylon 6 masterbatch, and colored masterbatch, the modified antibacterial and anti-ultraviolet dual-functional nylon 6 masterbatch accounts for 2.5-5% of the total mass of raw materials after mixing, and the colored masterbatch accounts for 3.0-4.0% of the total mass of raw materials after mixing. The colored masterbatch is colored masterbatch.

[0024] The production method of the antibacterial and anti-ultraviolet nylon 6 colored elastic yarn described in the present embodiment, it is raw material with nylon 6 slice, it is characterized in that comprising the steps:

[0025] a. Mix the colored masterbatch, modified antibacter...

Embodiment 2

[0030] The production method of antibacterial anti-ultraviolet nylon 6 colored stretch yarn described in the present embodiment, its steps are:

[0031] a. Dry the modified antibacterial and anti-ultraviolet dual-function nylon 6 masterbatch and black masterbatch at a temperature of 85°C for 8 hours, then turn off the power and let it cool down to below 50°C. The moisture content of materials, masterbatch and nylon 6 chips is controlled within 600PPM. Add the dried masterbatch to the masterbatch machine or use artificial methods. The antibacterial and anti-ultraviolet masterbatch is 2.5%, and the black masterbatch is mixed with nylon 6 slices with an intrinsic viscosity of 2.45 at a ratio of 3.0%. Melt extrusion is carried out in a screw extruder, the screw temperature is 258°C in the first zone, 268°C in the second zone, 270°C in the third zone, 270°C in the fourth zone, 266°C in the fifth zone, and the melt pressure is 12.5Mpa;

[0032] b. The fully melted melt is transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com