Novel double-motor mixing head control system and method for KR molten iron desulfuration

A hot metal desulfurization and control system technology, applied in the direction of stirring devices, lighting and heating equipment, furnace components, etc., can solve the adverse effects of process production status and equipment life, asynchronous master and slave motors of the stirring head, and synchronous effects of two motors, etc. problems, to achieve the effect of convenient production and maintenance, high synchronization, and simple debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

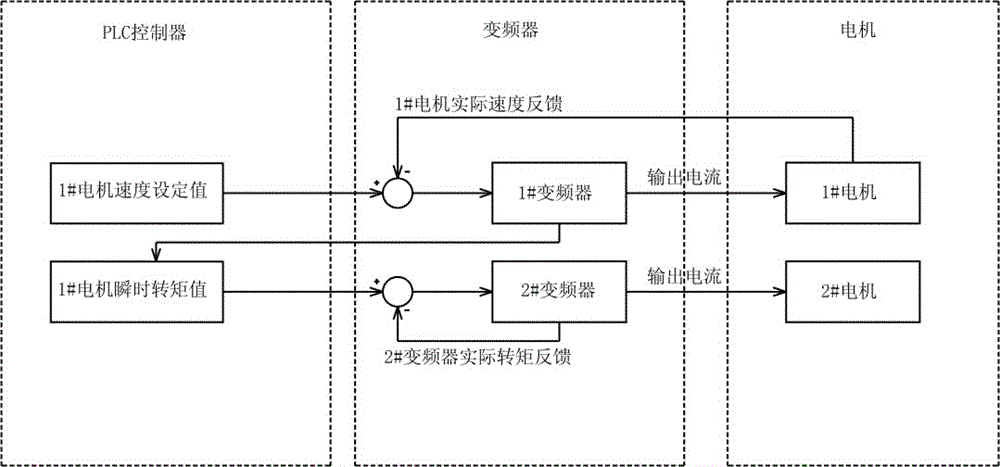

[0018] refer to figure 2 As shown, taking the currently commonly used 120tKR hot metal desulfurization station as an example, the new KR hot metal desulfurization dual-motor stirring head control system of the present invention includes: PLC controller, 1# stirring motor and corresponding 1# frequency converter, 2 #stirring motor and the corresponding 2# frequency converter; the 1# stirring motor and 2# stirring motor are hard-connected through the gearbox, and the PLC controller is equipped with a speed closed-loop PID controller and a torque filter; a speed closed-loop PID controller The output terminal of the torque filter is connected to the input terminal of the torque filter, and the output terminal of the torque filter is respectively connected to the input terminals of the 1# frequency converter and the 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com