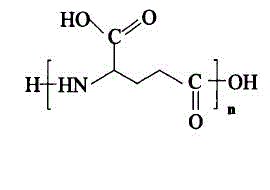

Recombinant corynebacterium glutamicum for producing gamma-polyglutamic acid as well as construction method and use of recombinant corynebacterium glutamicum

A technology of Corynebacterium glutamicum and polyglutamic acid, which is applied in the field of recombinant Corynebacterium glutamicum for producing γ-polyglutamic acid and its construction and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Example 1: Construction of recombinant Corynebacterium glutamicum C. glutamicum ATCC13869 (pEKEx2-BCA)

[0072] (1) Strains: Corynebacterium glutamicum C. glutamicum ATCC13869

[0073] (2) Foreign gene: plasmid pEKEx2-BCA

[0074] (3) Vector: E.coli / C.glutamicum shuttle vector pEKEx2 (Eggeling L, Bott M. Handbook of Corynebacterium glutamicum. CRC press, 2005, Boca Raton)

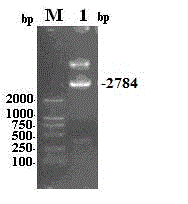

[0075] (4) Construction of recombinant plasmid pEKEx2-BCA

[0076] Using the genome of Bacillus subtilis TKPG011 as a PCR template, primers were designed to amplify pgsB, pgsC and pgsA, respectively. Connect both ends of the pgsB fragment to BamHI and HindⅢ sites respectively, the primers are: sense strand: 5'-gttgttggatccatgtggttatagcattatagcctgtg-3'; antisense strand: 5'-gttgttaagcttcatgcttacgagctgcttaacc-3', PCR amplification parameters are as follows: 95°C for 30s, 54°C for 50s, 72°C for 1min30s, a total of 30 cycles; connect the two ends of the pgsC fragment with HindⅢ and NdeI sites respecti...

Embodiment 2

[0079] Example 2: Fermentative production of γ-PGA by recombinant Corynebacterium glutamicum C. glutamicum ATCC13869 (pEKEx2-BCA)

[0080] (1) Fermentation strain: recombinant Corynebacterium glutamicum C. glutamicum ATCC13869 (pEKEx2-BCA)

[0081] (2) Two kinds of fermentation media

[0082] Biotin limited medium: 50g glucose, 30g (NH4) 2 SO 4 , 1g KH 2 PO 4 , 0.4g MgSO 4 ·7H 2 O, 0.01g FeSO4 7H 2 O, 0.01g MnSO 4 4H 2 O, 200μg vitamin B1HCl, 13.8ml soybean protein hydrolyzate (35g / L total nitrogen), 50gCaCO 3 (need to be sterilized separately), adjust the pH to 8.0 with KOH (the total volume is 1L).

[0083] Add Tween40 medium: 50g glucose, 30g (NH4) 2 SO 4 , 1g KH 2 PO 4 , 0.4g MgSO 4 ·7H 2 O, 0.01g FeSO4 7H 2 O, 0.01g MnSO 4 4H 2 O, 200μg vitamin B1HCl, 60μg biotin, 13.8ml soybean protein hydrolyzate (35g / L total nitrogen), 50g CaCO 3 (need to be sterilized separately), adjust the pH to 8.0 with KOH, and add Tween40 to a final concentration of 5mg / ml (th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com