4,4'-bis(2,4-diamidophenoxy)biphenyl high-temperature-resistant epoxy adhesive and preparation method thereof

A technology of diaminobiphenyl epoxy resin and diaminophenoxy, applied in the direction of online phenolic epoxy resin adhesive, adhesive, epoxy resin glue, etc., can solve the problem of high price, unfavorable large-scale promotion and application, poly The high cost of ether imide resin achieves the effect of convenient operation, good application prospect and strong hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of component A

[0045] Mix 100 g of N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenylmethane epoxy resin (epoxy value 0.8) with 19.9 g (0.05 mol) of 4,4'- Bis(2,4-diaminophenoxy)biphenyl was put into a reaction kettle, heated to 50°C, and stirred for 2 hours to obtain 119.9 g of a homogeneous and transparent copolymer, designated as A1.

[0046] Mix 100 g of N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenylmethane epoxy resin (epoxy value 0.8) with 15.9 g (0.04 mol) of 4,4'- Bis(2,4-diaminophenoxy)biphenyl was put into the reaction kettle, heated to 90°C, stirred and reacted for 0.5 hour to obtain 115.9 g of a homogeneous and transparent copolymer, designated as A2.

[0047] Diglycidyl 100 g of 4,5-epoxycyclohexane-1,2-dicarboxylate epoxy resin (epoxy value 0.85) was mixed with 18.7 g (0.047 mol) of 4,4'-bis(2,4 -diaminophenoxy)biphenyl was put into a reaction kettle, heated to 60° C., stirred and reacted for 1 hour to obtain 118.7 g of a homogeneous and transparen...

Embodiment 2

[0051] Preparation of Component B

[0052] At room temperature, put 39.8 grams (0.1 moles) of 4,4'-bis(2,4-diaminophenoxy)biphenyl and 830 grams of N,N-dimethylacetamide into the reaction kettle, stir and dissolve completely , add 104 g (0.2 mol) of 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl]propane dianhydride and 64.4 g (0.2 mol) of 3,3',4,4'- Tetracarboxybenzophenone dianhydride, stirred and reacted for 0.5-1 hour, obtained 1038.2 grams of homogeneous transparent solution, added 170 grams of toluene, heated to reflux, and carried out reflux water separation reaction, the temperature was 130 ° C, and the reaction time was 2 hours , After the reaction is completed, part of the organic solvent is separated so that its solid content is in the range of 15%-30%, which is denoted as B1.

[0053] At room temperature, mix 39.8 g (0.1 mol) of 4,4'-bis(2,4-diaminophenoxy)biphenyl with 100 g of N,N-dimethylacetamide and 536 g of N-methyl-2 - Pyrrolidone was added to the reactor, and afte...

Embodiment 3

[0056] Preparation of 4,4'-bis(2,4-diaminophenoxy)biphenyl type high temperature resistant epoxy adhesive

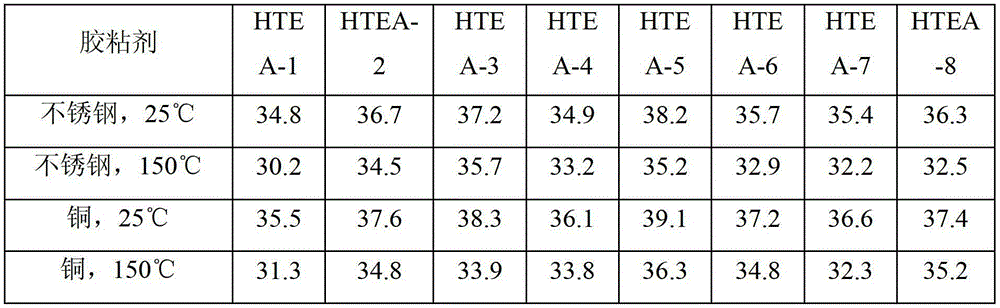

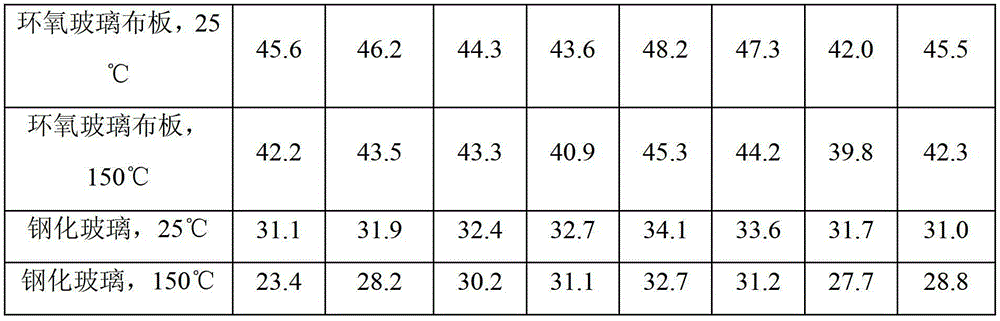

[0057] At room temperature, stir and mix components A and B according to the mass ratio of 1:1-2 to obtain a series of 4,4'-bis(2,4-diaminophenoxy)biphenyl type high temperature resistant rings Oxygen adhesive, denoted as HTEA-p, p is a natural number, the specific formula is shown in Table 1.

[0058] Table 1 Formula table of 4,4’-bis(2,4-diaminophenoxy)biphenyl type high temperature resistant epoxy adhesive Unit: gram

[0059] Component

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com