Matte cathode electrophoresis coating as well as preparation method and use method for same

A cathodic electrophoretic coating, matte technology, applied in the direction of electrolytic coating, electrophoretic plating, epoxy resin coating, etc., can solve the problem of matting efficiency, poor stability, coating leveling, mechanical performance reduction, and low gloss. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

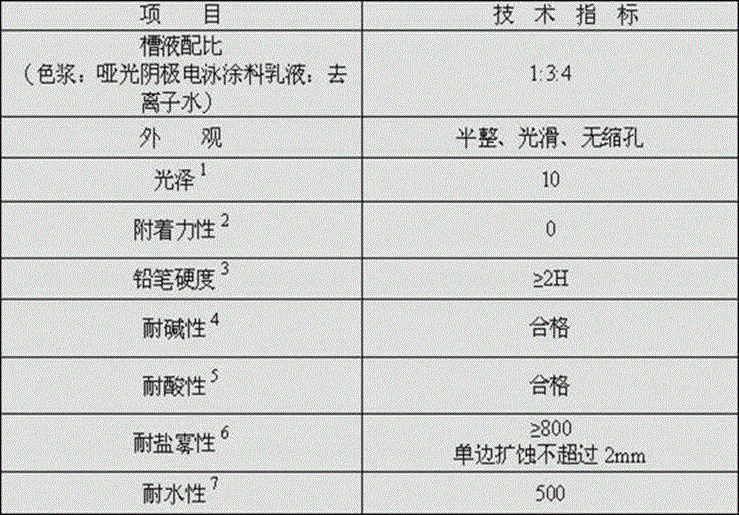

Examples

Embodiment 1

[0035] A preparation method of matte cathode electrophoretic paint includes the following steps:

[0036] A semi-blocked isocyanate curing agent is prepared by reacting isocyanate with a molar ratio of 1:0.8 and a blocking solvent at a temperature of 50°C for 3 hours;

[0037] Take the epoxy resin with a molar ratio of 1:0.4 and the diamine to react at 70°C for 1 hour to prepare a partially-opened epoxy resin; take a molar ratio of 1:1 with the partially-opened epoxy resin and The reaction time of polyamide at 80℃ is 2 hours to prepare a ring-opened epoxy resin; take the semi-closed isocyanate curing agent with a molar ratio of 1:0.5 and the ring-opened epoxy resin at a temperature of 80℃ React for 2 hours; generate semi-blocked isocyanate grafted amine-modified epoxy resin, which is the host resin.

[0038] Take the low-molecular-weight epoxy resin with a molar ratio of 1:0.5 and bisphenol A to react for 2 hours at a reaction temperature of 110°C, and carry out a chain extension re...

Embodiment 2

[0056] A preparation method of matte cathode electrophoretic paint includes the following steps:

[0057] A semi-blocked isocyanate curing agent is prepared by reacting isocyanate with a molar ratio of 1:1.5 and a blocking solvent at a temperature of 70°C for 5 hours;

[0058] Take the epoxy resin with a molar ratio of 1:0.8 and the diamine to react at 80°C for 2 hours to prepare a partially-opened epoxy resin; take a molar ratio of 1:1.5 with the partially-opened epoxy resin and The reaction time of polyamide at 90℃ is 3 hours to prepare a ring-opened epoxy resin; take the semi-closed isocyanate curing agent with a molar ratio of 1:1.0 and the ring-opened epoxy resin at a temperature of 90℃ React for 3 hours; generate semi-blocked isocyanate grafted amine-modified epoxy resin, namely host resin.

[0059] Take the low-molecular-weight epoxy resin with a molar ratio of 1:1.0 and bisphenol A to react for 3 hours at a reaction temperature of 120°C, and carry out chain extension reactio...

Embodiment 3

[0070] A preparation method of matte cathode electrophoretic paint includes the following steps:

[0071] (1) Preparation of semi-blocked isocyanate curing agent

[0072] A semi-blocked isocyanate curing agent is prepared by reacting isocyanate with a molar ratio of 1:1 and a blocking solvent at a temperature of 60°C for 4 hours;

[0073] (2) Preparation of main resin

[0074] (1) Take the epoxy resin and diamine with a molar ratio of 1:0.6 to react for 1.5 hours at 75°C to prepare a partially ring-opened epoxy resin;

[0075] (2) A ring-opened epoxy resin is prepared by taking a partially ring-opened epoxy resin with a molar ratio of 1:1.3 and a polyamide at 85°C for a reaction time of 2.5 hours;

[0076] (3) Take the semi-blocked isocyanate curing agent with a molar ratio of 1:0.7 and react with the ring-opening epoxy resin for 2.4 hours at a temperature of 85°C; the semi-blocked isocyanate grafted amine-modified epoxy resin is produced, namely Main body resin.

[0077] (3) Preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com