Concrete anti-cracking repairing agent and concrete applying the same

A technology of concrete and repairing agent, which is applied in the field of concrete and concrete repairing agent. It can solve the problems of easy cracks in concrete and poor self-repairing function of concrete anti-cracking performance, so as to reduce the risk of cracking, shorten the setting time, and inhibit the generation of cracks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

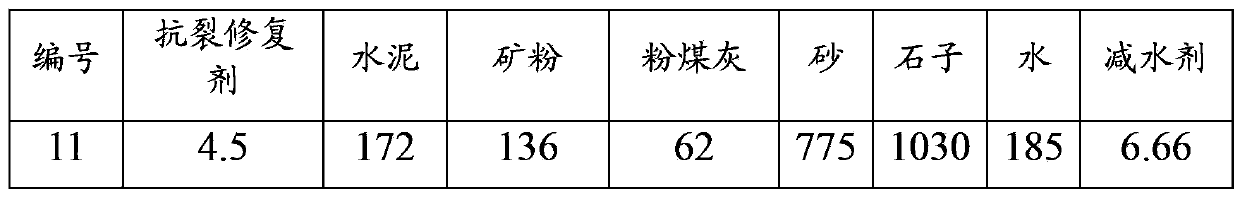

Embodiment 1

[0047] The components and weight ratios of the concrete anti-crack repair agent provided in this embodiment are:

[0048] Calcium quicklime (calculated as calcium oxide), 20 parts;

[0049] Micro silica fume, 45 parts;

[0050] Sodium bentonite, 15 parts;

[0051] Calcium hydrogen phosphate, 15 parts;

[0052] Lithium carbonate, 2 parts;

[0053] The surface modifier is polynaphthaldehyde sulfonic acid sodium salt, 2 parts;

[0054] fiber, 1 serving;

[0055] The fibers are formed by mixing polypropylene fibers with a size of 1-10mm and polypropylene fibers with a size of 10-19mm, and the mass ratio of the polypropylene fibers with a size of 1-10mm to that of 10-19mm is 3:7. The polypropylene fiber was purchased from Wuhan Tianhui Fiber Material Co., Ltd.

[0056] The preparation steps of the concrete anti-crack repair agent described in the present embodiment are:

[0057] (1) Mix the above-mentioned bentonite and calcium oxide in proportion and dry them for later use;...

Embodiment 2

[0063] The combination and weight ratio contained in a kind of concrete anti-crack repair agent provided by the present embodiment are:

[0064] Calcium quicklime (calculated as calcium oxide), 30 parts;

[0065] Micro silica fume, 50 parts;

[0066] Sodium bentonite, 10 parts;

[0067] Calcium hydrogen phosphate, 5 parts;

[0068] Lithium carbonate, 3 parts;

[0069] Surface modifier, 1 part;

[0070] Fiber, 1 part; the fiber is formed by mixing polyacrylonitrile fiber with a size of 1-10mm and polyacrylonitrile fiber with a size of 10-19mm; the polyacrylonitrile fiber with a size of 1-10mm and polyacrylonitrile fiber with a size of 10-19mm The mass ratio of fibers is 2:5; the polyacrylonitrile fibers are purchased from Wuhan Tianhui Fiber Material Co., Ltd.

[0071] The preparation method of the concrete anti-crack repair agent is the same as in Example 1.

[0072] The concrete anti-crack repair agent can be configured with concrete with strength grades of C20, C30, C4...

Embodiment 3

[0076] The combination and weight ratio contained in a kind of concrete anti-crack repair agent provided by the present embodiment are:

[0077] Calcium quicklime (calculated as calcium oxide), 40 parts;

[0078] Micro silica fume, 15 parts;

[0079] Sodium bentonite, 20 parts;

[0080] Calcium hydrogen phosphate, 13 parts;

[0081] Lithium carbonate, 5 parts;

[0082] Surface modifier polynaphthalene sulfonic acid sodium salt, 5 parts;

[0083] The fiber is, 2 parts; the fiber is made of a mixture of alkali-resistant glass fiber with a size of 1-10mm and an alkali-resistant glass fiber with a size of 10-19mm, and the alkali-resistant glass fiber with a size of 1-10mm and alkali-resistant glass fiber with a size of 10-19mm The mass ratio of glass fibers is 1:1; the alkali-resistant glass fibers are purchased from Wuhan Tianhui Fiber Material Co., Ltd.

[0084] The preparation method of the concrete anti-crack repair agent is the same as in Example 1.

[0085] The concret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mana absorption | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com