Modification of atomic force microscopy tips by deposition of nanoparticles with an aggregate source

A nanoparticle and ion cluster technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for sensing, can solve problems such as not allowing and modifying probes, and achieve easy implementation, good resolution and functionalization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

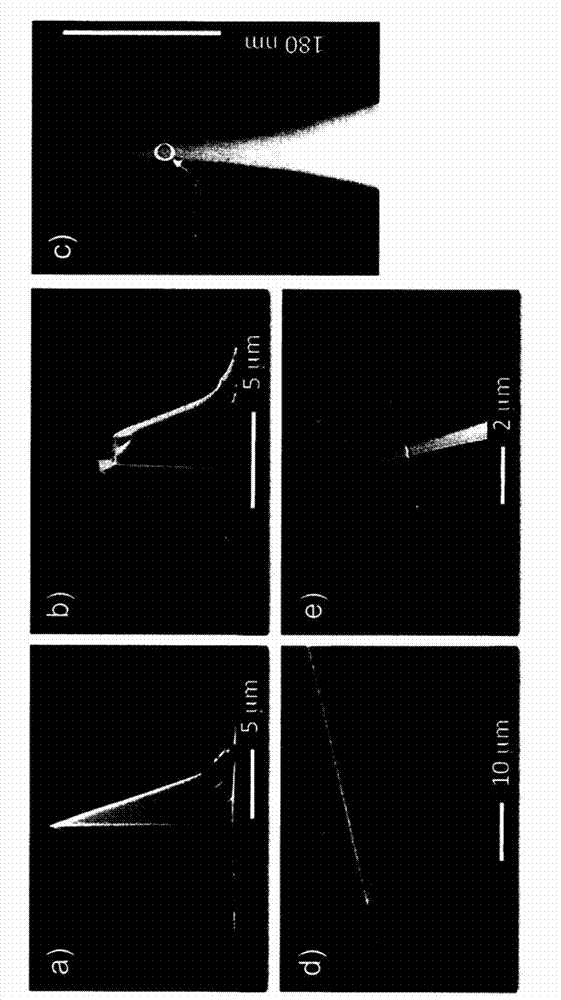

[0023] The invention will be illustrated below by means of a number of tests carried out by the inventors, clearly showing the characteristics and effects of the method of the invention for coating or modifying the surface of an AFM probe.

[0024] The tests were conducted to compare AFM images obtained with unmodified commercial AFM probes with AFM images obtained with commercial probes modified by depositing nanoparticles generated by the ion cluster source.

[0025] Under ultra-high vacuum conditions using an ion cluster source produced by Oxford Applied Research and Co 95 Au 5 Alloy blanks are deposited.

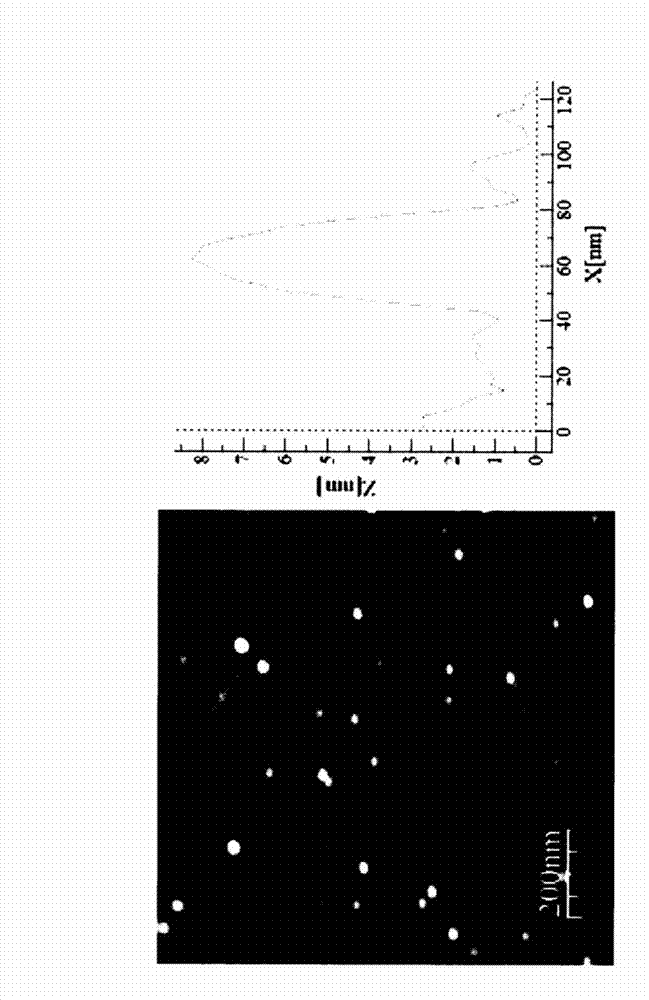

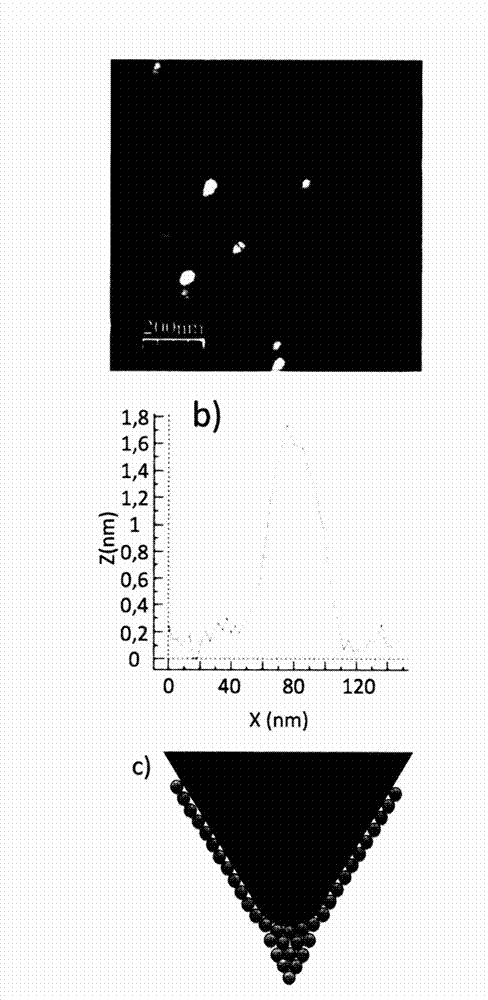

[0026] The nanoparticle production process was optimized to produce 2-3 nm spherical nanoparticles by means of ICS. For this, the relevant parameters are as follows: power applied to the magnetron: 20 W; cluster length: 50 mm; argon gas flow: 60 sccm; helium gas flow: 50 sccm; distance between ion cluster source and AFM probe: 190 mm; deposition time :2 minutes. ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com