Hybrid fiber high-crack-resisting and high-tenacity airfield pavement concrete and preparation method thereof

A technology of mixing fiber and concrete, which is applied in the field of concrete, can solve the problems of poor fiber dispersion and achieve the effects of improving durability, increasing bending toughness, and increasing safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

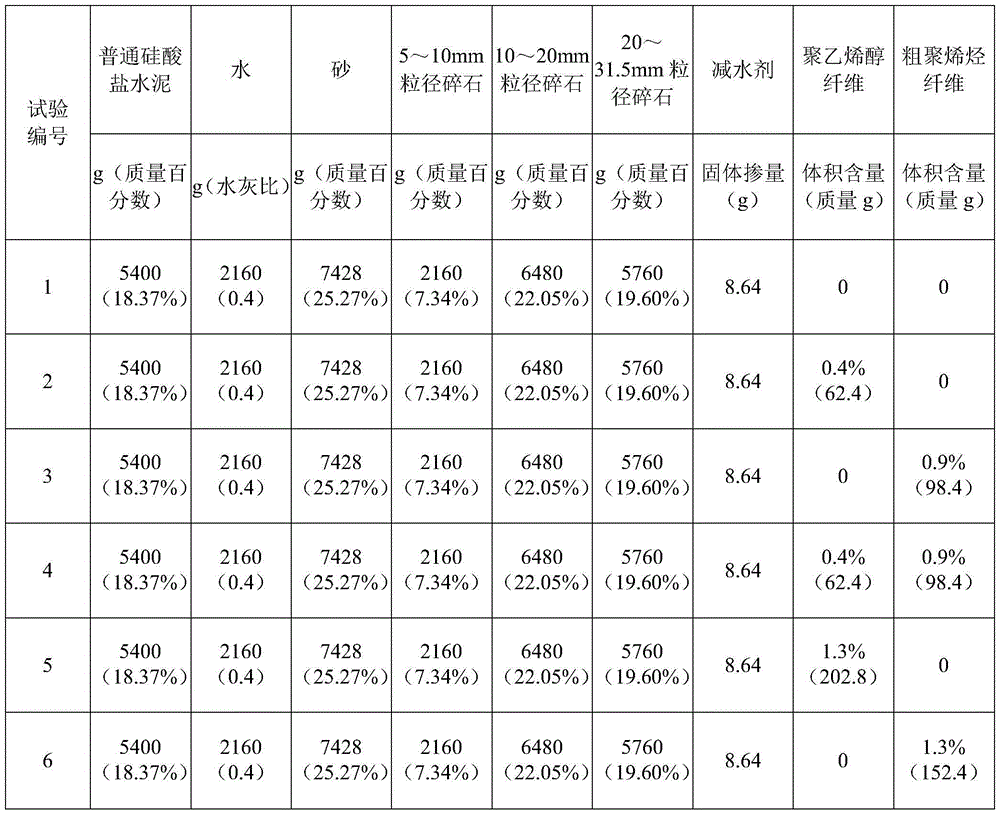

[0021] Table 1 Example mix ratio

[0022] for Table 1 The materials used in are described in detail:

[0023]

[0024] The grade of ordinary Portland cement used is PO.42.5.

[0025] The sand is construction sand, the particle gradation is 2-gradation area, and the fineness modulus is 2.7.

[0026] The water used complies with the provisions of "Concrete Water Standard" JGJ63-06, Table 1 The mass of reclaimed water is the mass of water after removing the water contained in the water reducing agent.

[0027] The stones are limestone crushed stones, using synthetic gradation, including three particle sizes ranging from (5-10) mm, (10-20) mm, (20-31.5) mm, and the particle size of the stones is from small to large. The mass ratio is 3:9:8.

[0028] The thick polyvinyl alcohol fibers used have a diameter of 1 mm, a length of 38 mm, and a density of 0.91×10 3 kg / m 3 .

[0029] The diameter of the fine polyethylene fibers used is 12 μm, the length is 12 mm; the densit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com