Copper sulphide classified nanometer structure material and preparation method thereof

A nanostructure, copper sulfide technology, applied in the direction of copper sulfide, nanotechnology, nanotechnology, etc., can solve the problems of easy introduction of impurities, difficult removal, complicated preparation process, etc., to achieve uniform structure size, small amount of raw materials, and simple operation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Add 0.5mmolCu(CH 3 COO) 2 Add 20mL dimethyl sulfoxide (DMSO, 0.28mol) and stir until completely dissolved to form a copper acetate solution;

[0028] Step 2: Put 0.5mmol sublimated sulfur powder into the above-mentioned copper acetate solution, stir to disperse it evenly, and obtain a mixed solution;

[0029] Step 3: Put the above mixed solution into the reaction kettle, keep it warm at 120°C for 2 hours, and then cool it to room temperature 25°C in the air;

[0030] Step 4: Collect the black powder by centrifugation, wash it with deionized water and ethanol, and dry it in vacuum at 50° C. for 3 hours to obtain the product, namely copper sulfide hierarchical nanostructure material.

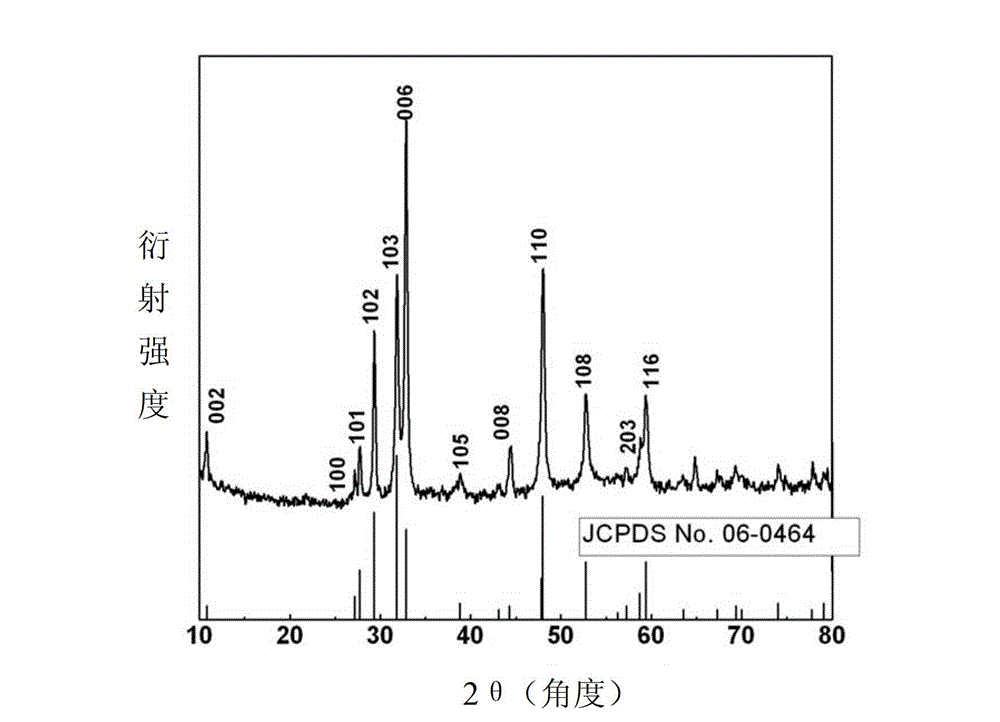

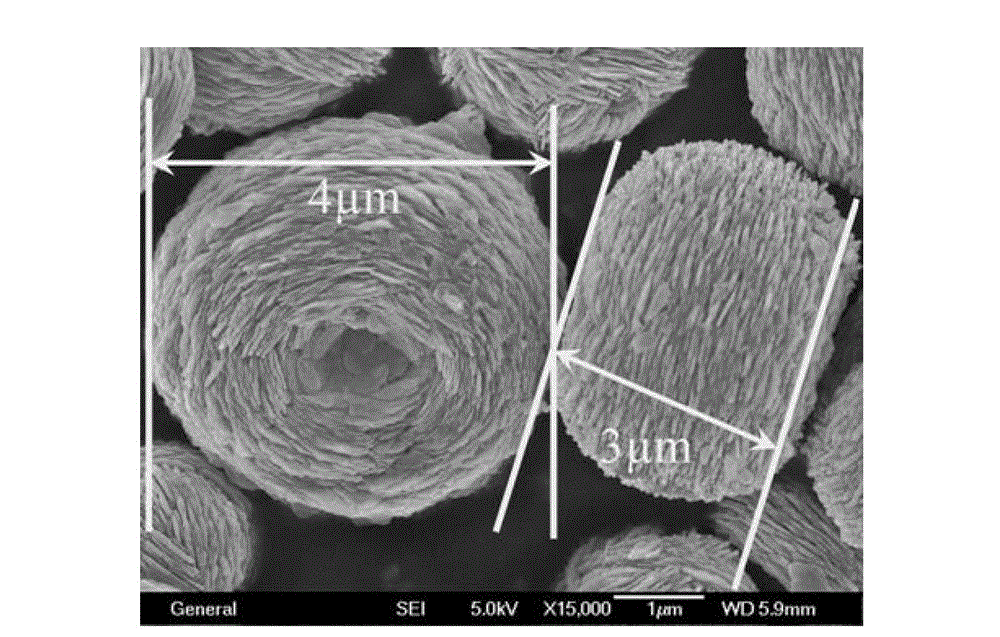

[0031] The obtained copper sulfide hierarchical nanostructure material is characterized by X-ray diffraction (XRD), and its X-ray diffraction pattern is as follows figure 1 As shown, it can be seen that the product of the present invention is copper sulfide of the hexagonal phase...

Embodiment 2

[0034] Step 1: Add 0.5mmolCu(CH 3 COO) 2 Add 20mL dimethyl sulfoxide (DMSO, 0.28mol) and stir until completely dissolved to form a copper acetate solution;

[0035] Step 2: Put 0.5mmol sublimated sulfur powder into the above-mentioned copper acetate solution, stir to disperse it evenly, and obtain a mixed solution;

[0036] Step 3: Put the above mixture into the reaction kettle, keep it warm at 120°C for 1 hour, and then cool it to room temperature 25°C in the air;

[0037] Step 4: Collect the black powder by centrifugation, wash it with deionized water and ethanol, and dry it in vacuum at 50° C. for 3 hours to obtain the product, namely copper sulfide hierarchical nanostructure material.

[0038] The obtained copper sulfide hierarchical nanostructure material is characterized by X-ray diffraction (XRD), and it can be known that the product of the present invention is copper sulfide of hexagonal phase.

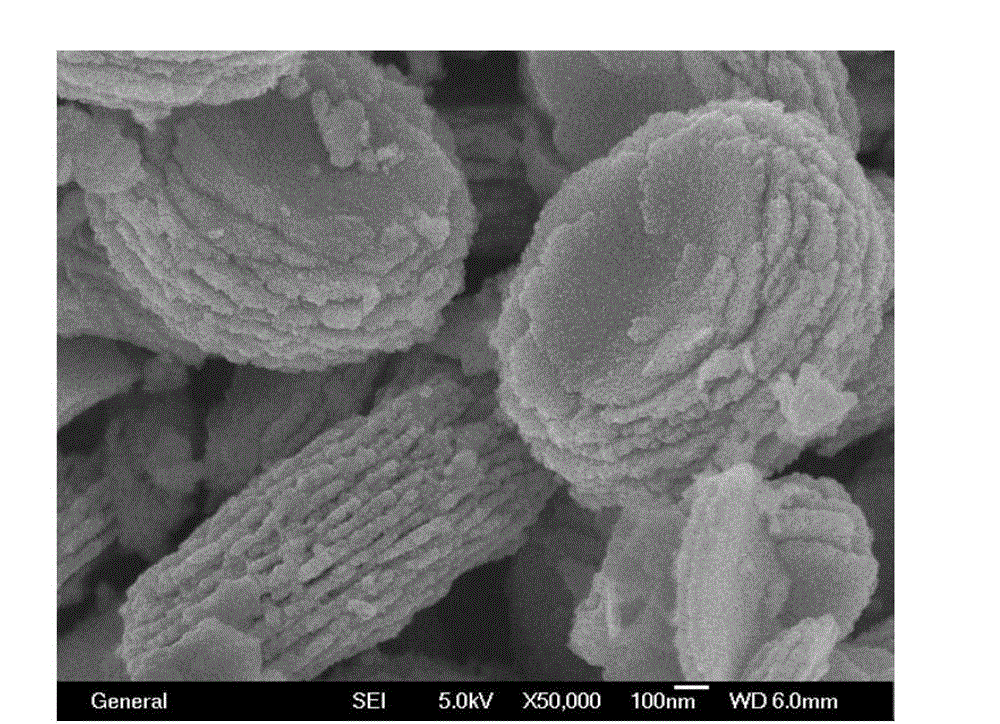

[0039] The obtained copper sulfide hierarchical nanostructure material w...

Embodiment 3

[0041] Step 1: Add 0.5mmolCu(CH 3 COO) 2 Add 20mL dimethyl sulfoxide (DMSO, 0.28mol) and stir until completely dissolved to form a copper acetate solution;

[0042] Step 2: Put 0.5mmol sublimated sulfur powder into the above-mentioned copper acetate solution, stir to disperse it evenly, and obtain a mixed solution;

[0043] Step 3: Put the above mixed solution into a reaction kettle, keep it warm at 100°C for 2 hours, and then cool it to room temperature 25°C in air.

[0044] Step 4: Collect the black powder by centrifugation, wash it with deionized water and ethanol, and dry it in vacuum at 50° C. for 3 hours to obtain the product, namely copper sulfide hierarchical nanostructure material.

[0045] The obtained copper sulfide hierarchical nanostructure material is characterized by X-ray diffraction (XRD), and it can be known that the product of the present invention is copper sulfide of hexagonal phase.

[0046] The obtained copper sulfide hierarchical nanostructure materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com