Carrying device with vertical lifting and rail transfer translation functions

A bearing device, vertical lifting technology, applied in the direction of lifting device, lifting frame, buildings where cars are parked, etc., can solve the problems of inconvenient access, huge equipment, complex structure, etc., to reduce the trouble of transposition and improve work efficiency , Easy to move in and out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below, the invention will be described in detail in conjunction with the accompanying drawings and specific embodiments:

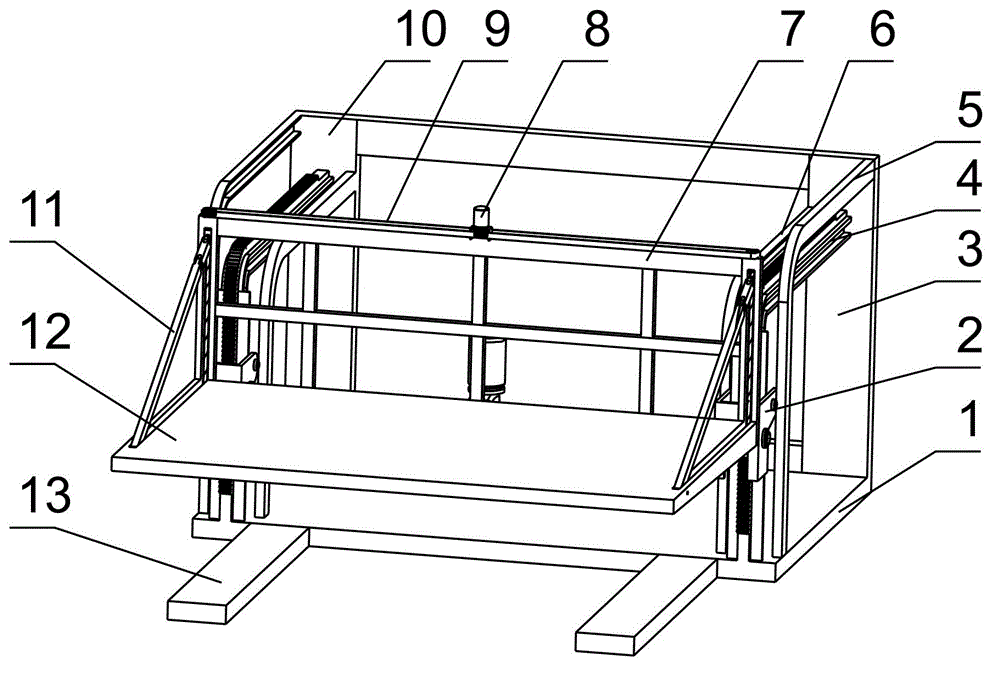

[0035] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 Embodiments of the invention are shown. Its composition: consists of base 1, lifting and changing track walking mechanism 2, right guide rail assembly support plate 3, main supporting guide rail 4, first guide rail 5, second guide rail 6, connecting bracket 7, gear motor 8, chain 9, left guide rail assembly Support plate 10, telescopic tension link 11, load-bearing pallet 12, load-bearing balance plate 13, main motor 14, reduction box 15, left transmission shaft 16, right transmission shaft 17, inner sliding wheel interface plate 18, rack guide rail 19, Vertical chute 20, slide block 21, sprocket wheel 22, joint 23, horizontal chute 24, pillar 25, support body 201, load-bearing inner sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com