Preparation method of Fe3O4/Au composite nanoparticles

A composite nanoparticle and nanoparticle technology, which is applied in the field of preparation of Fe3O4/Au composite nanoparticle, can solve the problems such as no discovery, and achieve the effect of mild reaction conditions, good colloidal stability, and simple synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Take 60mg of mPEG-COOH, 19.17mg of EDC and 11.51mg of NHS in a reaction flask, add 5mL of ultrapure water to dissolve it, and then react with magnetic stirring for 3h. Dissolve 50mg PEI in 5mL ultrapure water. The activated mPEG-COOH aqueous solution (5 mL) was added dropwise to the above 5 mL PEI aqueous solution, and the reaction was stirred for three days. The reaction mixture was dialyzed against distilled water for three days (6 times, 2 L / time) with a dialysis bag with a molecular weight cut-off of 14,000 to remove by-products and impurities, and the product mPEG-PEI was freeze-dried and stored at -20°C for future use. The mPEG-PEI synthesized above was dissolved in 10 mL of ultrapure water. Add 5.4mL HAuCl 4 solution (30mg / mL), stirred for half an hour. Then add ice-bathed 0.9mL NaBH 4 (45.4mg) solution (ethanol / ultrapure water, v / v=1:2), after continuing to stir for two hours, then dialyzed against distilled water for three days (6 times, 2L / time) with a dia...

Embodiment 2

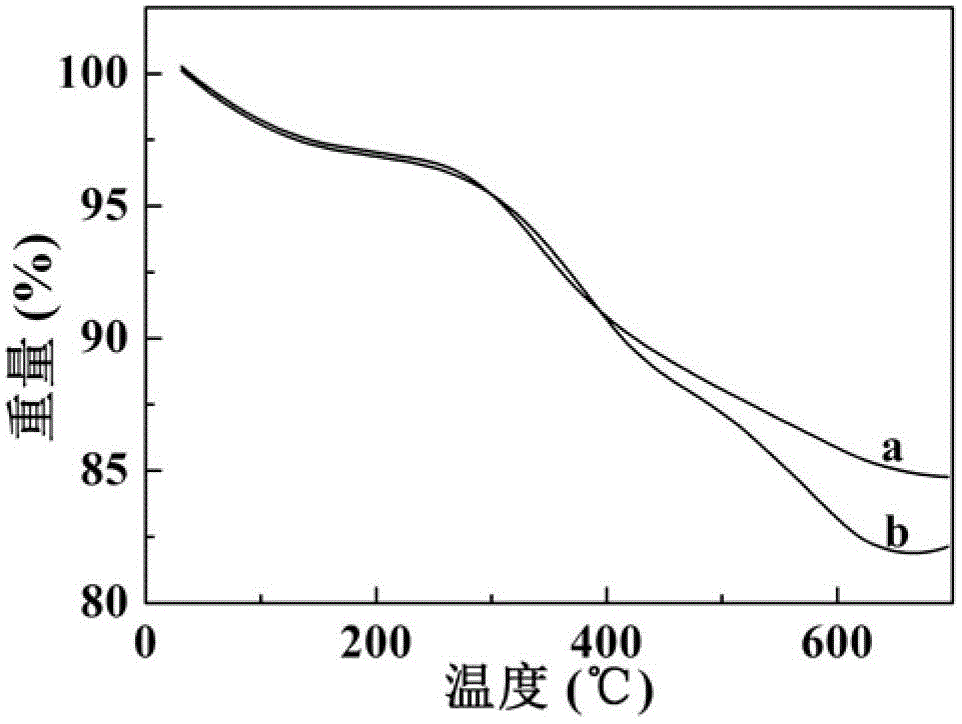

[0066] Take 0.5mL Fe respectively 3 o 4 -PEI-mPEG-Au (comparative example 3) and Fe 3 o 4 - PEI-Ac-mPEG-Au (Example 1) nanoparticles were lyophilized for thermogravimetric analysis. like image 3Shown is the TG change curve of nanoparticles before and after acetylation. It can be seen from the figure that the weight loss of nanoparticles before acetylation is 15.14% ( image 3 a), The weight loss of nanoparticles after acetylation is 17.71%. After calculation, the TG change of nanoparticles before and after acetylation was 2.57%. This shows that Fe 3 o 4 Acetylation Modification of Au / Au Composite Nanoparticles.

Embodiment 3

[0068] Take 0.1mL Fe respectively 3 o 4 -PEI-mPEG-Au (comparative example 3) and Fe 3 o 4 - PEI-Ac-mPEG-Au (Example 1) nanoparticles were prepared into a 1.5 mL aqueous solution with ultrapure water, and then used to measure surface potential and hydrodynamic diameter (see Table 1). The successful acetylation of nanoparticles was further confirmed by the measurement of Zeta potential. Potential measurements (Table 1) show that Fe 3 o 4 -The surface potential of PEI-mPEG-Au nanoparticles is +27.4mV, after the acetylation reaction, the obtained Fe 3 o 4 -PEI-Ac-mPEG-Au nanoparticles surface potential dropped to +12.8mV. The results showed that the amino groups on the surface of the nanoparticles had been successfully acetylated. However, the surface potential of the nanoparticles did not reach neutrality after acetylation, which may be because some of the amino groups used to stabilize the gold nanoparticles and Fe3O4 nanoparticles on the surface cannot undergo acetylati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com