Processing method and application of enoki mushroom roots

A technology of Flammulina velutipes roots and mushroom roots, which is applied in the processing field of Flammulina velutipes roots, can solve problems such as the environmental impact of Flammulina velutipes roots, poor taste of Flammulina velutipes root powder, and poor taste of Flammulina velutipes roots, so as to improve food utilization and facilitate The effect of body absorption and loose texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]One, the processing method of Flammulina velutipes mushroom root, the steps are as follows:

[0038] 1. Remove impurities and compost from the fresh mushroom roots with a water content of 50wt%, remove diseased roots, rotten roots and polluted mushroom roots,

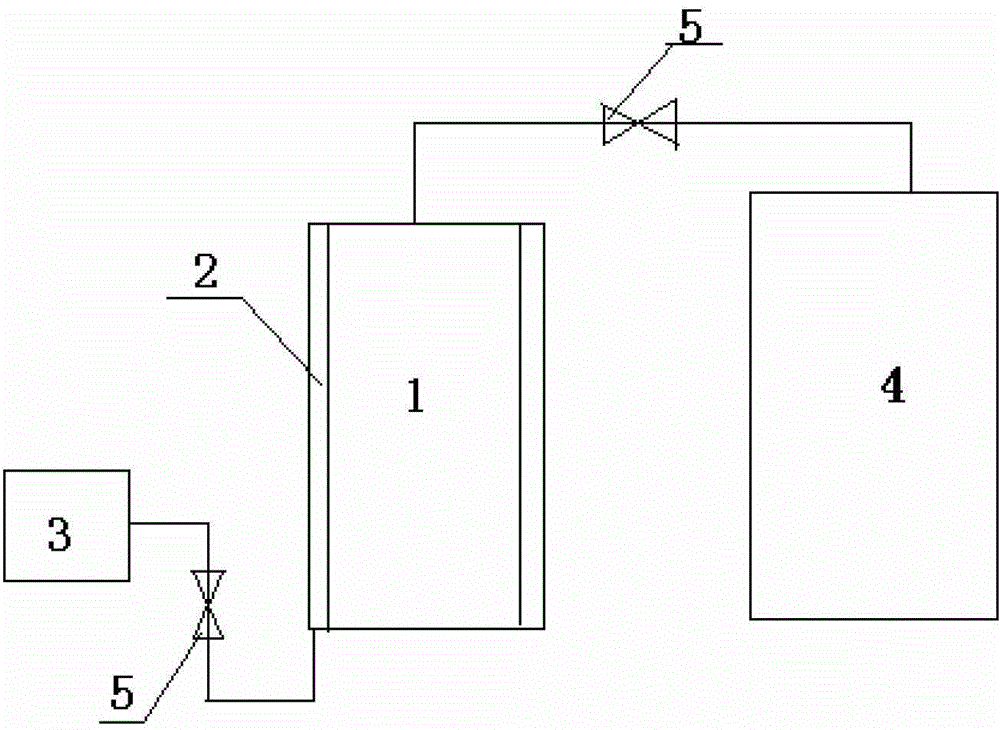

[0039] 2. Put the roots of Flammulina velutipes with a water content of 50wt% into the expansion tank of the expansion equipment, the amount of the roots of Flammulina velutipes is 20% of the volume of the expansion tank by volume ratio, and seal the expansion tank;

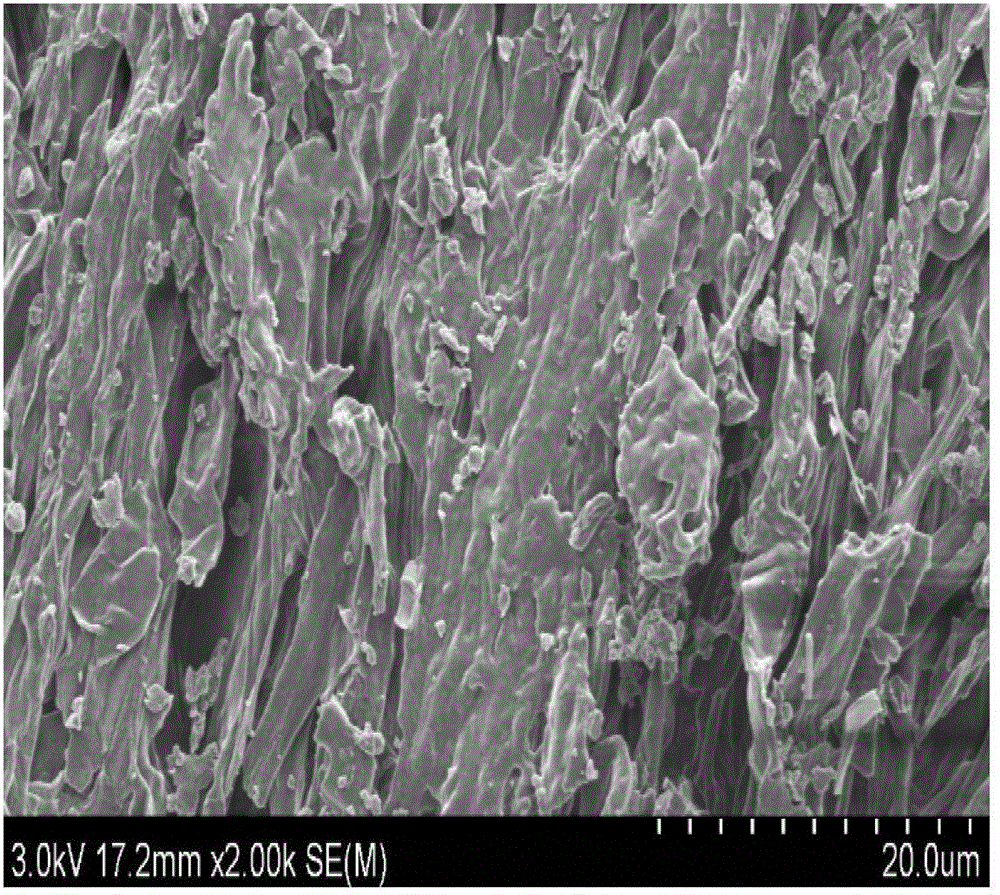

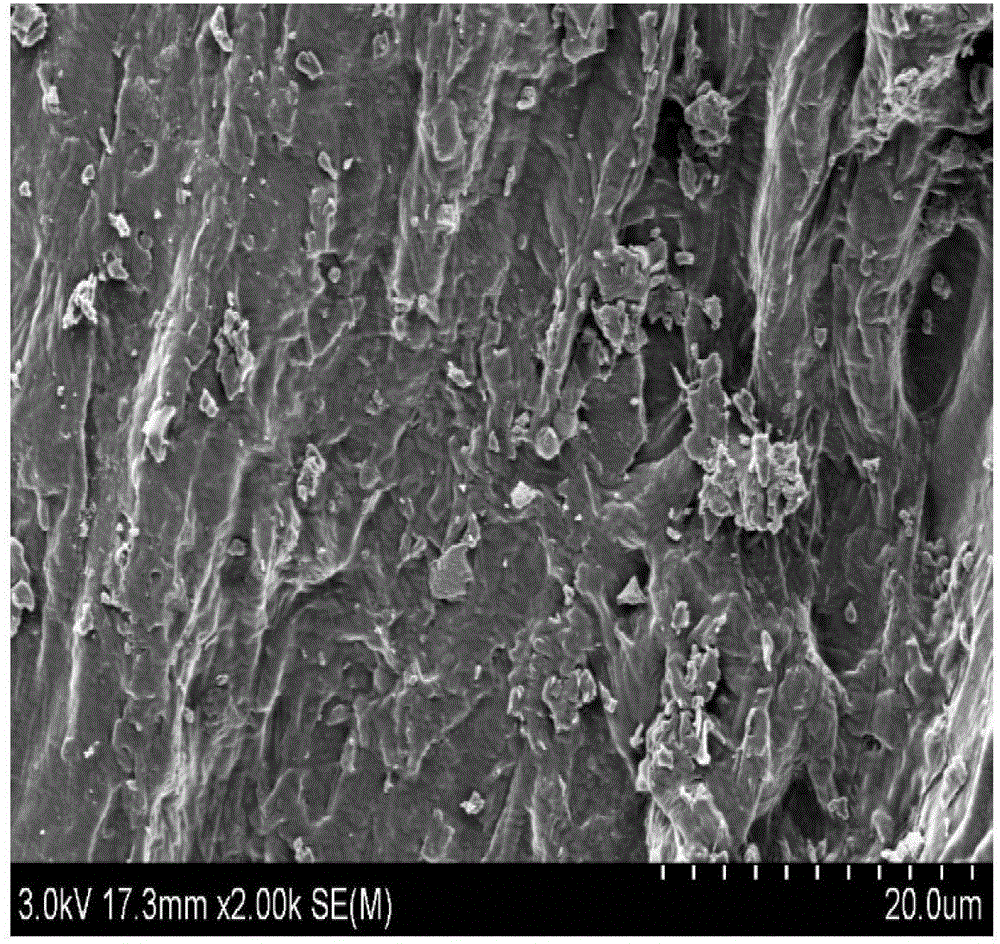

[0040] 3. Heat and pressurize the Flammulina velutipes root in the expansion tank, so that the temperature in the expansion tank rises to 100 ° C, and when the pressure rises to 0.15 MPa, keep it for 10 minutes. When the temperature and pressure are stable, pump the vacuum tank of the expansion equipment Vacuum, when the pressure of the vacuum tank is -0.1MPa, open the valve between the expansion tank and the vacuum tank, the temperature and pressure...

Embodiment 2

[0050] The preparation method of Flammulina velutipes root powder, the steps are as follows:

[0051] 1. Take fresh mushroom roots with a water content of 40wt% to remove impurities and culture materials, remove diseased roots, rotten roots and polluted mushroom roots,

[0052] 2. Put fresh Flammulina velutipes roots into the expansion tank of the puffing equipment, the volume ratio of the roots of Flammulina velutipes is 25% of the volume of the expansion tank, and seal the expansion tank;

[0053] 3. Heat and pressurize the Flammulina velutipes root in the expansion tank, so that the temperature in the expansion tank rises to 100 ° C, and when the pressure rises to 0.2 MPa, keep it for 15 minutes. When the temperature and pressure are stable, pump the vacuum tank of the expansion equipment Vacuum, when the pressure of the vacuum tank is -0.1MPa, open the valve between the expansion tank and the vacuum tank, the temperature and pressure in the expansion tank will drop instant...

Embodiment 3

[0064] The preparation method of Flammulina velutipes root powder, the steps are as follows:

[0065] 1. Take fresh mushroom roots with a water content of 70wt% to remove impurities and culture materials, remove diseased roots, rotten roots and polluted mushroom roots,

[0066] 2. Put fresh Flammulina velutipes roots into the expansion tank of the puffing equipment, the volume ratio of the roots of Flammulina velutipes is 30% of the volume of the expansion tank, and seal the expansion tank;

[0067] 3. Heat and pressurize the Flammulina velutipes root in the expansion tank, so that the temperature in the expansion tank rises to 95 ° C, and when the pressure rises to 0.12 MPa, keep it for 15 minutes. When the temperature and pressure are stable, pump the vacuum tank of the expansion equipment Vacuum, when the pressure of the vacuum tank is -0.1MPa, open the valve between the expansion tank and the vacuum tank, the temperature and pressure in the expansion tank will drop instant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com