A light-emitting device and its preparation method

A technology of light-emitting components and substrates, applied in chemical instruments and methods, light-emitting materials, electrical components, etc., can solve the problems of low luminous efficiency, achieve enhanced luminous efficiency, enhanced spontaneous radiation, and simple process preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

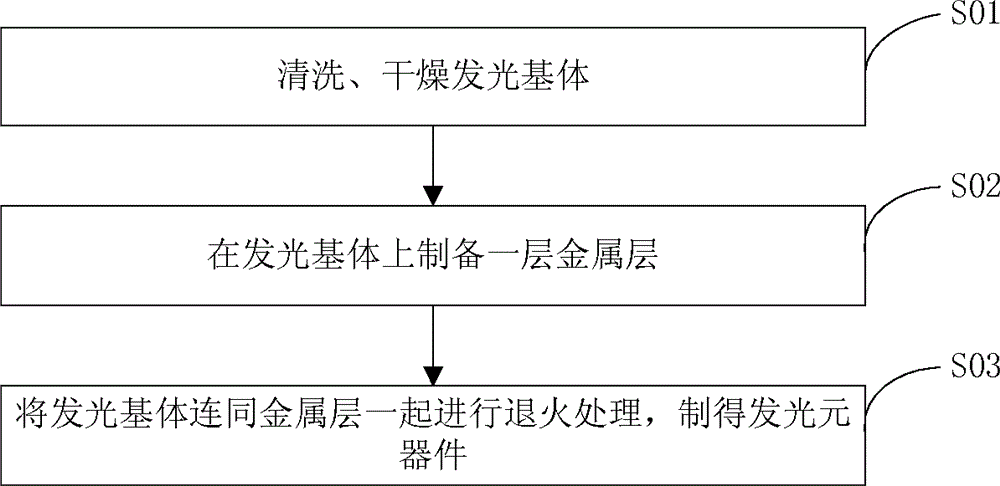

[0023] The present invention also provides a method for preparing the above-mentioned light-emitting components, such as figure 2 As shown, its preparation process includes:

[0024] S01. Clean the luminescent substrate in acetone, deionized water, and absolute ethanol in sequence, and then dry or blow dry;

[0025] S02. Prepare a metal layer on the surface of the light-emitting substrate;

[0026] S03, performing annealing treatment on the light-emitting substrate prepared with the metal layer in a vacuum state, and after cooling, a light-emitting device containing a metal microstructure in the metal layer is prepared.

[0027] In step S01 of the above-mentioned preparation method, the light-emitting matrix adopts Eu-doped Y 2 o 3 System transparent luminescent ceramics, its chemical composition is Y 2 o 3 : Eu; In the process of use, the transparent ceramic needs to be machined, polished, etc. to make shapes that meet the needs of various applications, that is, the lum...

Embodiment 1

[0040] Y doped with Eu 2 o 3 System transparent ceramic sheet, that is, the chemical composition is Y 2 o 3 : Eu luminescent ceramics as a luminescent substrate, and then use magnetron sputtering equipment to deposit a metal silver layer with a thickness of 20 nanometers on the transparent ceramic surface, and then place it in a vacuum of less than 1×10 -3 Under the vacuum environment of Pa, annealing at 300° C. for half an hour, and then cooling to room temperature, a light-emitting element having a metal layer with a metal microstructure is obtained.

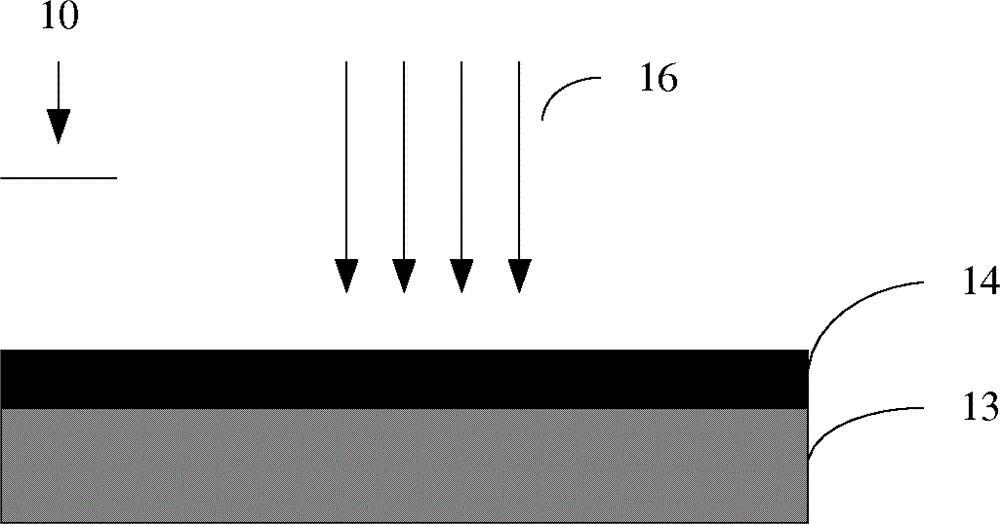

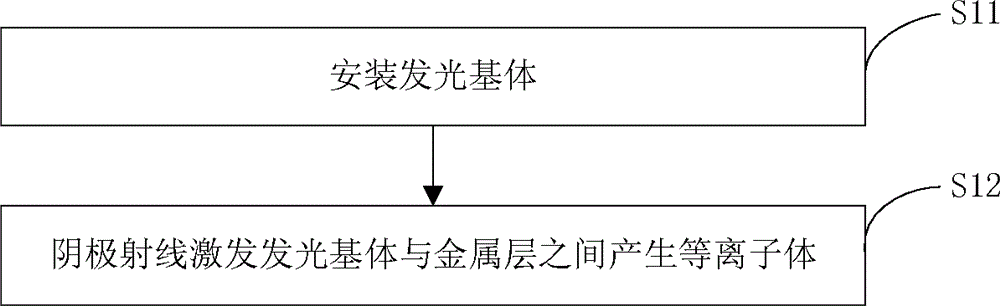

[0041] Spectral test is carried out on the light-emitting element prepared above, and the cathode ray generated by the electron gun is used to bombard the light-emitting element, and the electron beam first penetrates the metal layer and then excites Y 2 o 3 : Eu transparent ceramics emit light, producing such as Figure 4 The luminescent spectrum shown in the figure shows that the luminescent material is a green luminesc...

Embodiment 2

[0043] The difference between Example 2 and Example 1 is that a metal gold layer with a thickness of 200 nanometers is deposited on the surface of the luminescent substrate, and then it is placed in a vacuum with a degree of less than 1×10 -3 In a vacuum environment of Pa, annealing treatment was performed at a temperature of 650° C. for 1 hour, and then cooled to room temperature to obtain a light-emitting element with a metal layer with a metal microstructure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com