Multichannel value of resistance automation measuring system

A measurement system and road resistance technology, applied in the field of automatic multi-channel resistance measurement system, can solve the problems of error-prone, slow data processing speed, limited data volume, etc., and achieve high reliability

Inactive Publication Date: 2013-06-05

SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

View PDF11 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the aging test of traditional infrared detector components, the resistance test of the photosensitive element needs to be disconnected from the power supply and its current-limiting resistor first, and then manually measured regularly through the connection line drawn from the vacuum container, which greatly increases the inaccuracy and inaccuracy of the resistance test. Convenience, the data measured at the same time need to be entered manually, errors are prone to occur during the test process, the amount of accumulated data is extremely limited, the data processing speed is slow, and real-time processing cannot be performed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

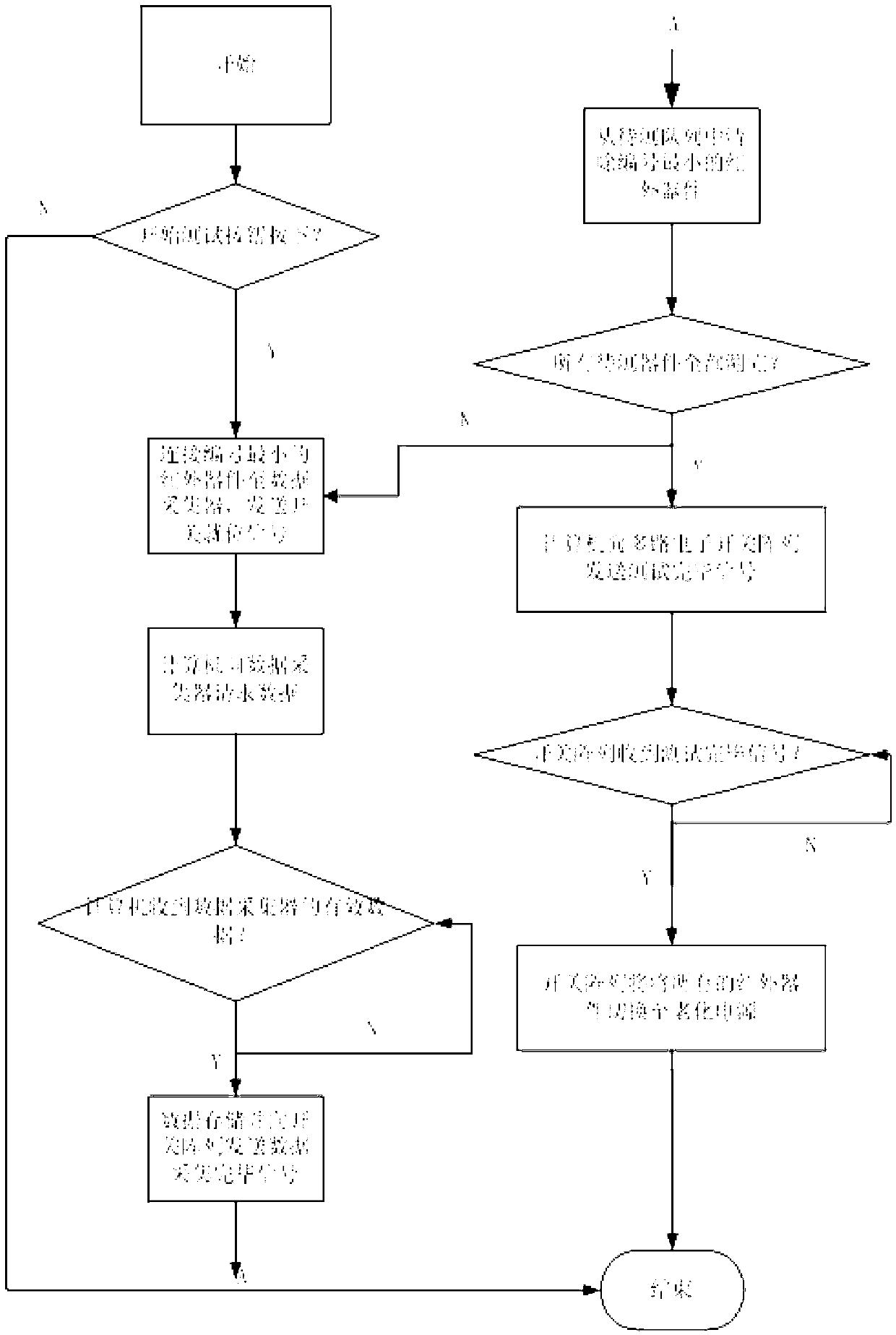

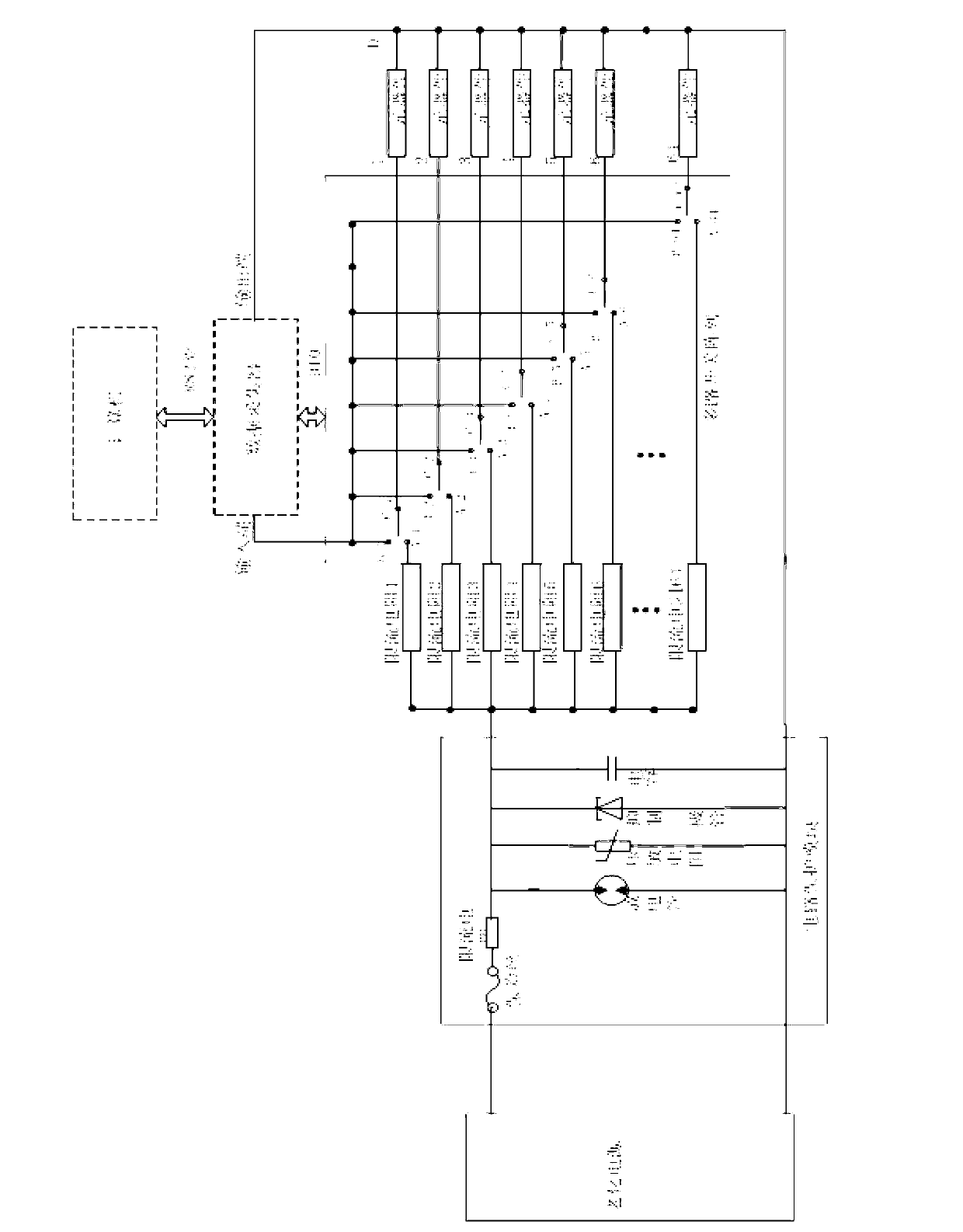

The invention discloses a multichannel value of resistance automation measuring system. The multichannel value of resistance automation measuring system comprises a burn-in power source, a multichannel electronic switch array, a data collector, a current-limiting resistance, a circuit protection unit and a computer, wherein the multichannel electronic switch array is a multichannel single-pole double-bladed switch array, according to a test requirement of arbitrary one-channel component in multichannel infrared devices, the channel component is disconnected with the burn-in power source and is connected with the data collector to finish automatic switch between a try state and a test state of the component; simultaneously, the data collector is used for measuring value of resistance of the switched component to achieve the aim that the value of the resistance is automatically measured. By the adoption of a method that the computer sends command to a RS232 interface means of the data collector, the measured data are transferred to the computer to be stored; by the adoption of the system, the facts that the value of the resistance of the multichannel component is automatically measured and the data of the multichannel component is automatically stored are achieved, the rate, the accuracy and the data size of collecting component burn-in data are improved.

Description

technical field The invention relates to a fully automatic multi-channel resistance measurement system, in particular to a multi-channel resistance automatic measurement system. Background technique In the aging test of traditional infrared detector components, the resistance test of the photosensitive element needs to be disconnected from the power supply and its current-limiting resistor first, and then manually measured regularly through the connection line drawn from the vacuum container, which greatly increases the inaccuracy and inaccuracy of the resistance test. Convenience. At the same time, the measured data needs to be entered manually. Errors are prone to occur during the test process. The amount of accumulated data is extremely limited. The data processing speed is slow and cannot be processed in real time. Contents of the invention Based on the above-mentioned difficulties in researching the resistance test of multi-channel infrared detectors, this patent di...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01R27/02

Inventor 曹岚张海燕朱宪亮夏王季鹏庄腹蓉陆华杰龚海梅

Owner SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com