Three-way vibrating table

A vibrating table and vibrating motor technology, applied in the field of mechanical engineering, can solve problems such as the inability to unidirectionally excite the vibrating table to realize the vibration environment, and achieve the effect of small size and complex vibration environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

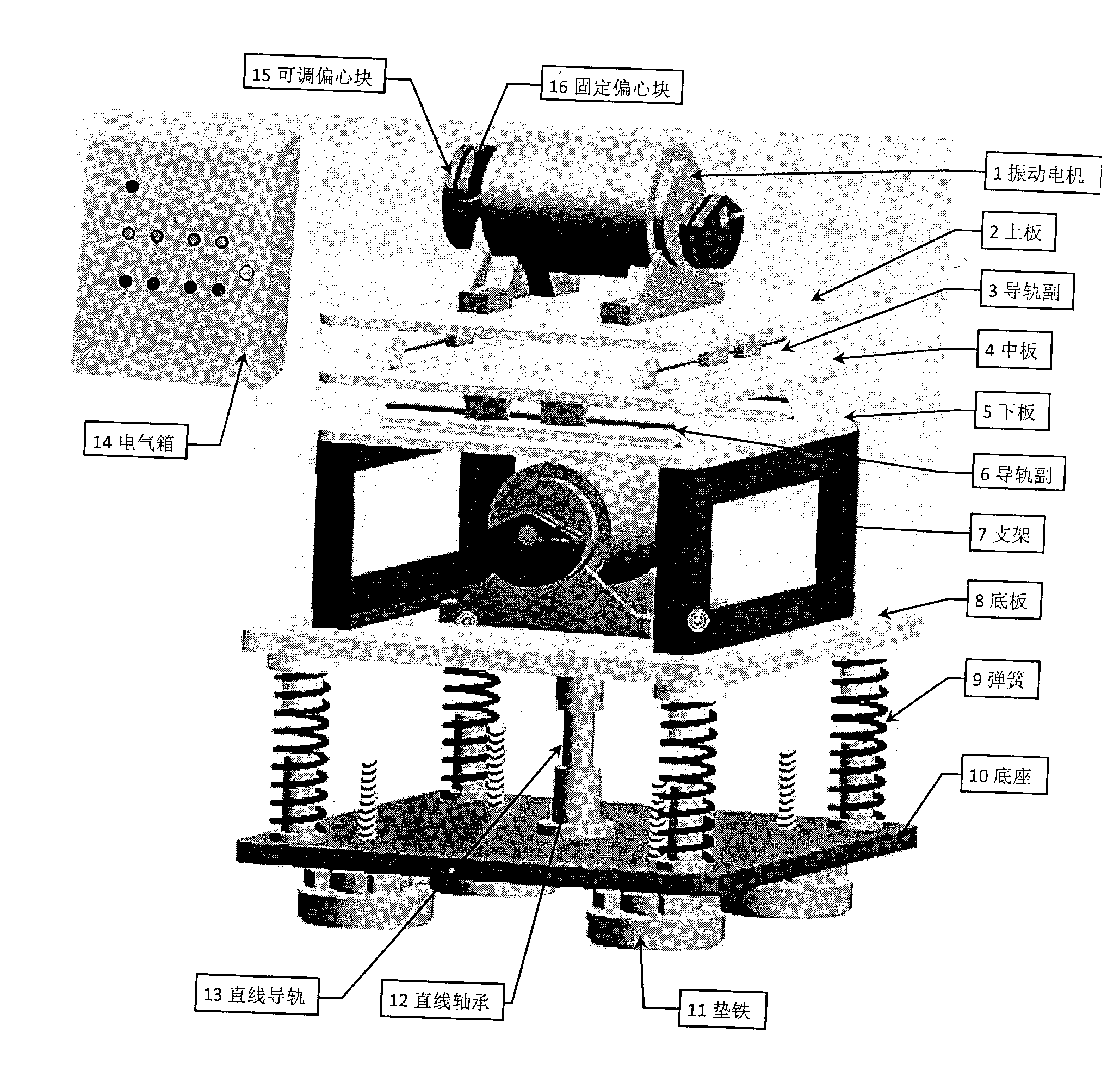

[0021] The three-way vibrating table of the present embodiment is shown in Figure 1, mainly consists of vibrating motor 1, upper plate 2, guide rail pair 3, middle plate 4, lower plate 5, guide rail pair 6, bracket 7, base plate 8, spring 9, base 10, pad iron 11, linear bearing 12, linear guide rail 13, electrical box 14 and other components, vibration motor 1 also includes adjustable eccentric block 15, fixed eccentric block 16.

[0022] Said two vibrating motors are respectively fixedly mounted on the upper plate 2 and the bottom plate 8 in the direction of 90°; The other two parallel guide rail pairs 6 forming 90° with the guide rail pair 3 of the middle plate 4 are installed on the lower plate 5 .

[0023] Said base plate 8 is supported on the base 10 by four springs 9, and the center is guided by a linear guide rail 13 and a linear bearing 12.

[0024] Said vibration motor 1 output shaft two ends are all equipped with adjustable eccentric block 15 and fixed eccentric blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com