Textile reinforced concrete (TRC) tube restraining reinforced concrete column

A reinforced concrete column, fabric reinforcement technology, applied in the direction of columns, piers, pillars, etc., can solve the problems of poor high temperature resistance, difficult construction, easy aging, etc., and achieve the effects of low cost, high construction efficiency, and good earthquake resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments are given below in conjunction with the accompanying drawings, and the TRC pipe-constrained reinforced concrete column and the manufacturing method of the present invention will be described in detail.

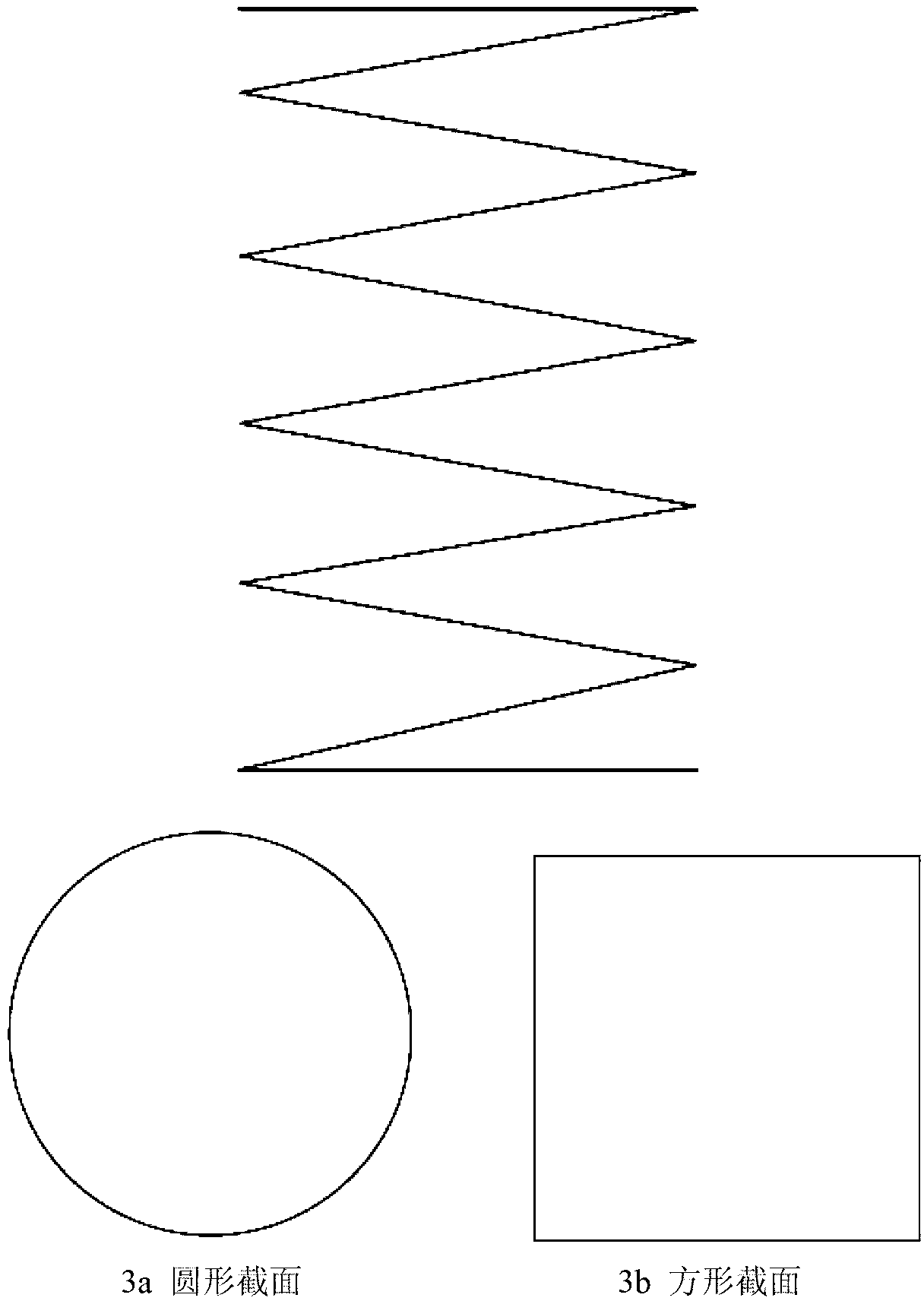

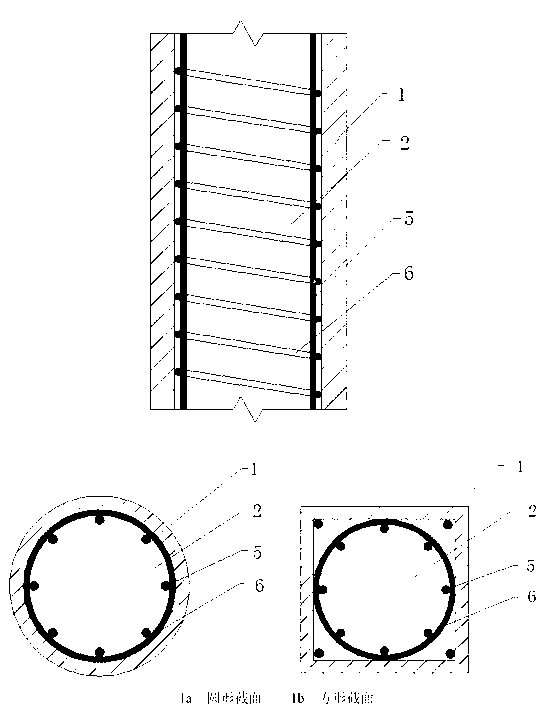

[0019] like figure 1 Shown is a schematic structural diagram of a TRC-constrained reinforced concrete column, which includes a TRC pipe 1 and a reinforced concrete column 2 cast in the TRC pipe. Determine the cross-sectional form of the column according to the architectural design (circular ( figure 1 a), square ( figure 1 b)) and height, configure longitudinal bars 5 and spiral stirrups 6 according to the structural design (circular ( image 3 a), square ( image 3 b)).

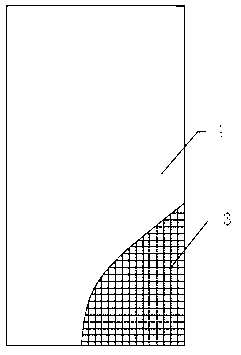

[0020] In the factory, the woven mesh 3 is first placed in the mold for making the TRC pipe 1, and the prepared high-performance concrete 4 is poured to make the TRC pipe 1; the longitudinal reinforcement bars 5 and the spiral stirrups 6 are bound to form a reinforcement cage....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com