High-elasticity and high-stretchability shadowless glue and preparation method thereof

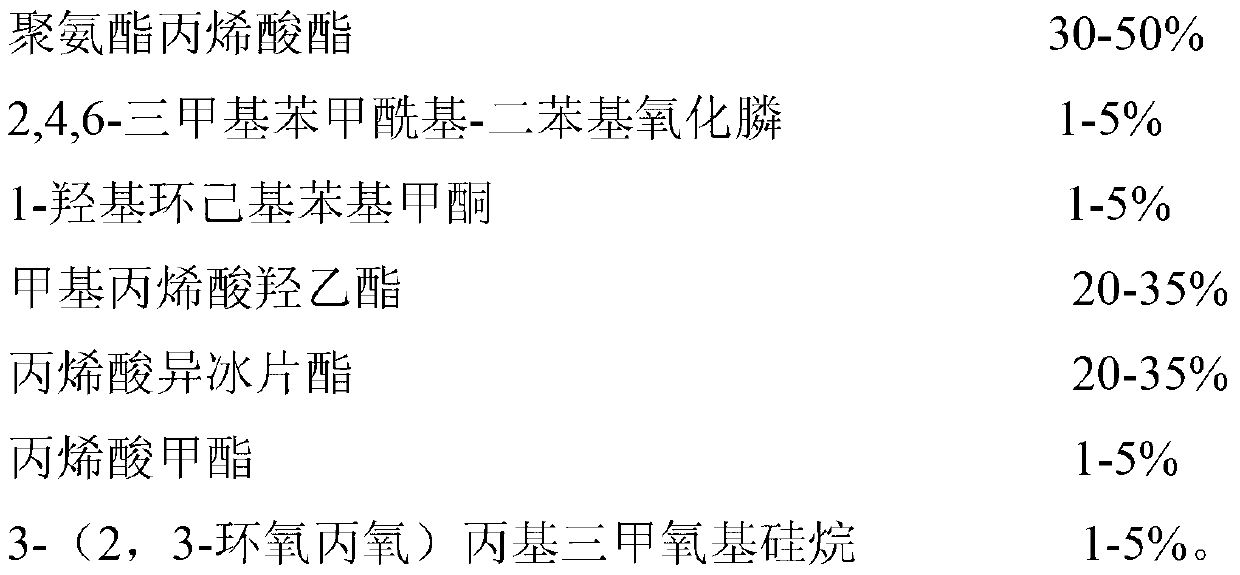

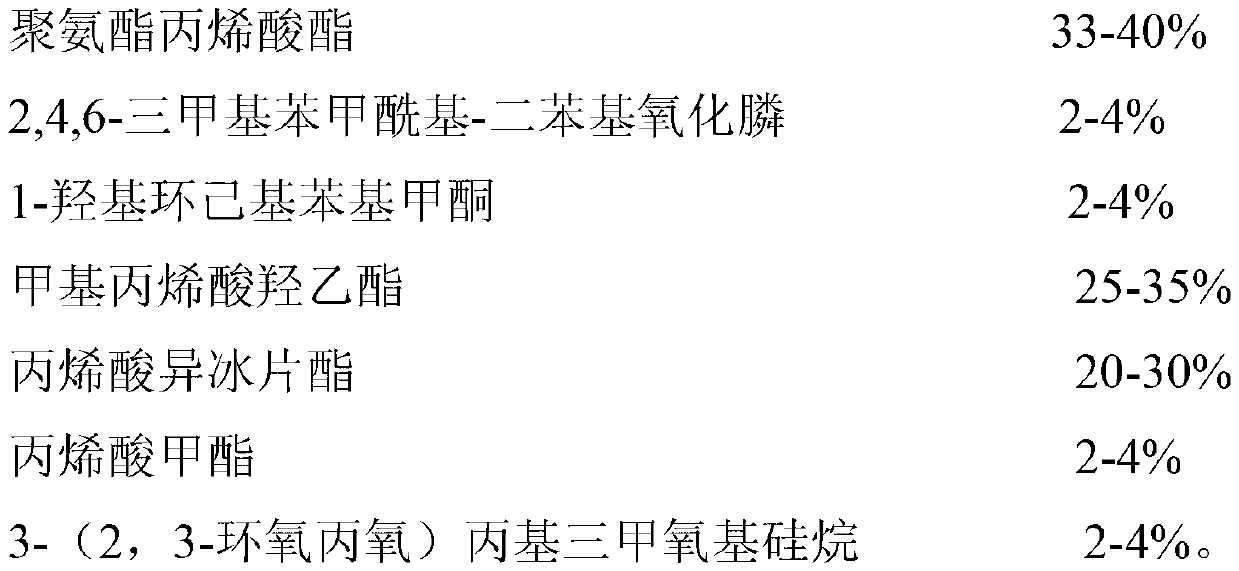

A stretchable, shadowless adhesive technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of low elongation, inability to absorb stress, poor weather resistance, etc., and achieve bonding High strength, long service life, high elongation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: A high-elastic and high-stretch shadowless adhesive, which is made of the following raw materials in weight percentage: 30% polyurethane acrylate, 2,4,6-trimethylbenzoyl-diphenyl oxide Phosphine 2%, 1-hydroxycyclohexyl phenyl ketone 5%, hydroxyethyl methacrylate 21%, isobornyl acrylate 35%, methyl acrylate 2%, 3-(2,3-epoxypropoxy) Propyltrimethoxysilane 5%.

[0020] The amount of each raw material used to produce 2000kg of shadowless glue of the present invention is: urethane acrylate 600kg, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide 40kg, 1-hydroxycyclohexylphenylmethanol Ketone 100kg, hydroxyethyl methacrylate 420kg, isobornyl acrylate 700kg, methyl acrylate 40kg, 3-(2,3-epoxypropoxy)propyltrimethoxysilane 100kg.

[0021] Its preparation method is:

[0022] (1) Add urethane acrylate to the mixer, then add 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 1-hydroxycyclohexyl phenyl ketone, and hydroxyethyl methacrylate in sequence, Turn the mixer fro...

Embodiment 2

[0024] Embodiment 2: a kind of shadowless glue of high elasticity and high stretchability, it is made of the raw material of following percentage by weight:

[0025] Urethane acrylate 35%, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide 3%, 1-hydroxycyclohexyl phenyl ketone 3%, hydroxyethyl methacrylate 28%, acrylate iso Bornyl ester 28%, methyl acrylate 2%, 3-(2,3-epoxypropoxy)propyltrimethoxysilane 1%.

[0026] The amount of each raw material used to produce 2000kg of shadowless glue of the present invention is: urethane acrylate 700kg, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide 60kg, 1-hydroxycyclohexylphenylmethanol Ketone 60kg, hydroxyethyl methacrylate 560kg, isobornyl acrylate 560kg, methyl acrylate 40kg, 3-(2,3-epoxypropoxy)propyltrimethoxysilane 20kg.

[0027] Its preparation method is:

[0028] (1) Add urethane acrylate to the mixer, then add 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 1-hydroxycyclohexyl phenyl ketone, and hydroxyethyl methacrylate in seque...

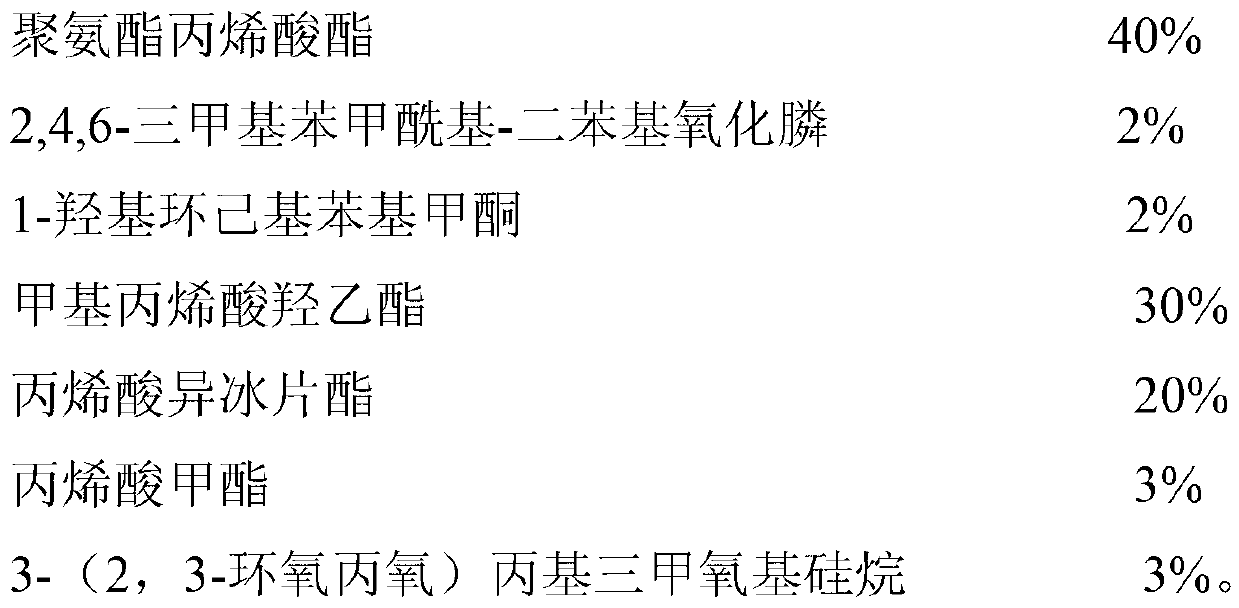

Embodiment 3

[0030] Embodiment 3: a kind of shadowless glue of high elasticity and high stretchability, it is made of the raw material of following percentage by weight:

[0031] Urethane acrylate 40%, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide 2%, 1-hydroxycyclohexyl phenyl ketone 2%, hydroxyethyl methacrylate 25%, isoacrylate Bornyl ester 25%, methyl acrylate 3%, 3-(2,3-epoxypropoxy)propyltrimethoxysilane 3%.

[0032] The amount of each raw material used to produce 2000kg of shadowless glue of the present invention is: urethane acrylate 800kg, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide 40kg, 1-hydroxycyclohexylphenylmethanol Ketone 40kg, hydroxyethyl methacrylate 500kg, isobornyl acrylate 500kg, methyl acrylate 60kg, 3-(2,3-epoxypropoxy)propyltrimethoxysilane 60kg.

[0033] Its preparation method is:

[0034] (1) Add urethane acrylate to the mixer, then add 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 1-hydroxycyclohexyl phenyl ketone, and hydroxyethyl methacrylate in sequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com