SiO/C composite cathode material of lithium ion battery and preparation method of SiO/C composite cathode material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle stability and high calcination temperature, achieve high specific capacity, low operating temperature, and facilitate industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

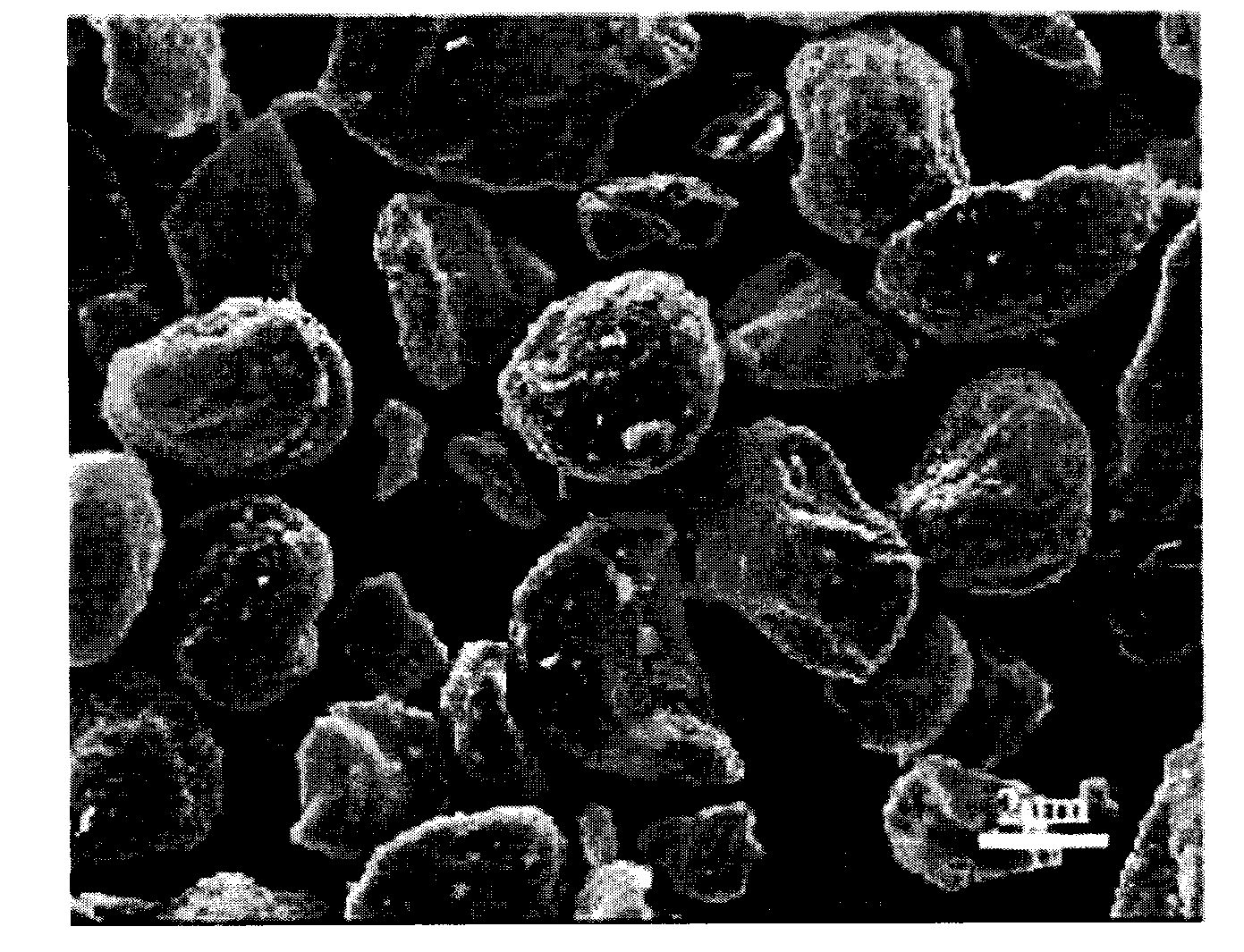

[0033] Artificial graphite 36g (purchased from Shanghai Shanshan Technology Co., Ltd., trade name YT7-38, D 50 =26μm) in 1L of ethanol to ultra-fine grinding to the average particle size D 50 to 318nm, add 109g tetraethyl orthosilicate TEOS, 4.4g polyvinylpyrrolidone PVP and 2L water, continue to stir to make the dispersion even; N 2 Under 500 ℃ pyrolysis for 5 hours to obtain black powder 65g; 220g citric acid (C 6 h 8 o 7 .H 2 O) be dissolved in 2L ethanol, add above-mentioned solid wherein and continue ball milling after 1 hour, evaporate solvent at room temperature, in 100%N 2 Perform pyrolysis at 450°C for 3 hours, crush and classify through a 300-mesh sieve to obtain the average particle size D 50 7.5μm SiO / C composite anode material.

[0034] Electrochemical performance test method:

[0035] In order to test the performance of the SiO / C composite negative electrode material for the lithium ion battery prepared in this example, a lithium ion battery was prepared ...

Embodiment 2

[0039] Artificial graphite 36g (purchased from Shanghai Shanshan Technology Co., Ltd., trade name is FSN-1, D 50 =25μm) in 1.2L of ethanol to ultra-fine grinding to the average particle size D 5 To 352nm, add 81g tetraethyl orthosilicate TEOS, 5.9g polyvinylpyrrolidone PVP and 2L water, continue to stir to make the dispersion uniform; N 2 Under 500°C pyrolysis for 6 hours, 60g of black powder was obtained; 186g of citric acid (C 6 h 8 o 7 .H 2 O) be dissolved in 2L ethanol, add above-mentioned solid wherein and continue ball milling after 1 hour, evaporate solvent at room temperature, in 100%N 2 Perform pyrolysis at 450°C for 3 hours, crush and classify through a 300-mesh sieve to obtain the average particle size D 50 8.2μm SiO / C composite anode material. According to the same electrochemical test method as in Example 1, the first discharge specific capacity of the prepared silicon-carbon composite negative electrode material is 591mAh / g, the charge specific capacity is...

Embodiment 3

[0041] Artificial graphite 36g (purchased from Shanghai Shanshan Technology Co., Ltd., trade name is FSN-1, D 50 =25μm) in 1.5L ethanol to ultra-fine grinding to the average particle size D 5 375nm, add 62g tetraethyl orthosilicate TEOS, 4g polyvinylpyrrolidone PVP and 2L water, continue to stir to make the dispersion uniform; 2 Under 550°C pyrolysis for 6 hours, 56g of black powder was obtained; 162g of citric acid (C 6 h 8 o 7 .H 2 O) be dissolved in 1.8L ethanol, add above-mentioned solid wherein and continue ball milling after 1 hour, evaporate off solvent at room temperature, in 100%N 2 Perform pyrolysis at 500°C for 2 hours, and pass through a 300-mesh sieve to obtain the average particle size D 50 8.5μm SiO / C composite anode material.

[0042] According to the same electrochemical test method as in Example 1, the first discharge specific capacity of the prepared silicon-carbon composite negative electrode material is 550mAh / g, the charge specific capacity is 506mA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com