Cyclone gas flotation separator

A technology of cyclone air flotation and separator, which is applied in the direction of liquid separation, separation method, flotation water/sewage treatment, etc., which can solve the problem of inability to meet the requirements of oily sewage treatment, low fluctuation resistance of hydrocyclone, increased investment and application Cost and other issues, to achieve high oil removal efficiency, strengthen the interaction between air bubbles and oil droplets, and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the specific implementation manner of this patent is described in further detail.

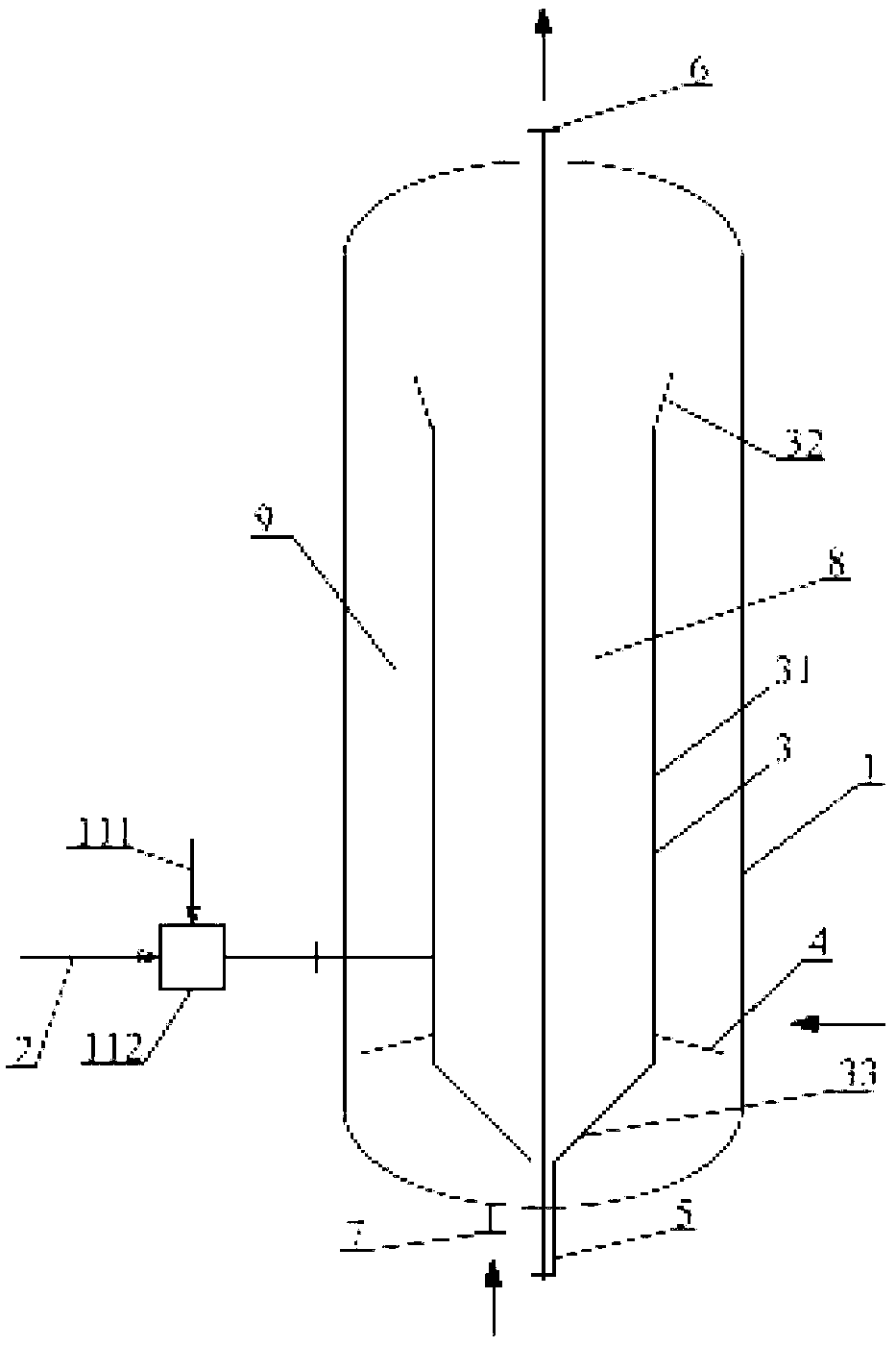

[0023] Such as figure 1 As mentioned above, it is mainly composed of a tank body 1, a sewage inlet pipe 2, an inner cylinder 3, a partition 4, a scum outlet 6, a treated water outlet 7, a sewage outlet 5, a gas-liquid mixed sewage inlet pipe 111, a mixer 112, and the like. The tank body 1 is divided into an inner cylinder area 8 and an outer cylinder area 9 by an inner cylinder 3 . The inner cylinder 3 is arranged coaxially with the tank body 1 , and the inner cylinder 3 is composed of a middle cylinder section 31 , an upper inverted horn section 32 and a lower cone section 33 .

[0024] Such as figure 2 As mentioned above, as a method of the present invention, an annular oil collection groove 11 is provided on the inner side of the tank close to the opening of the upper end of the inner cylinder, so that the separation occurs gas from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com