Method for treatment of low-concentration mercury containing wastewater by utilizing modified pelelith

A volcanic rock, low-concentration technology, applied in chemical instruments and methods, adsorption water/sewage treatment, inorganic chemistry, etc., can solve the problems of no patented technology and mercury-containing wastewater, and achieve easy operation, environmental protection and pollution-free Treatment effect, effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

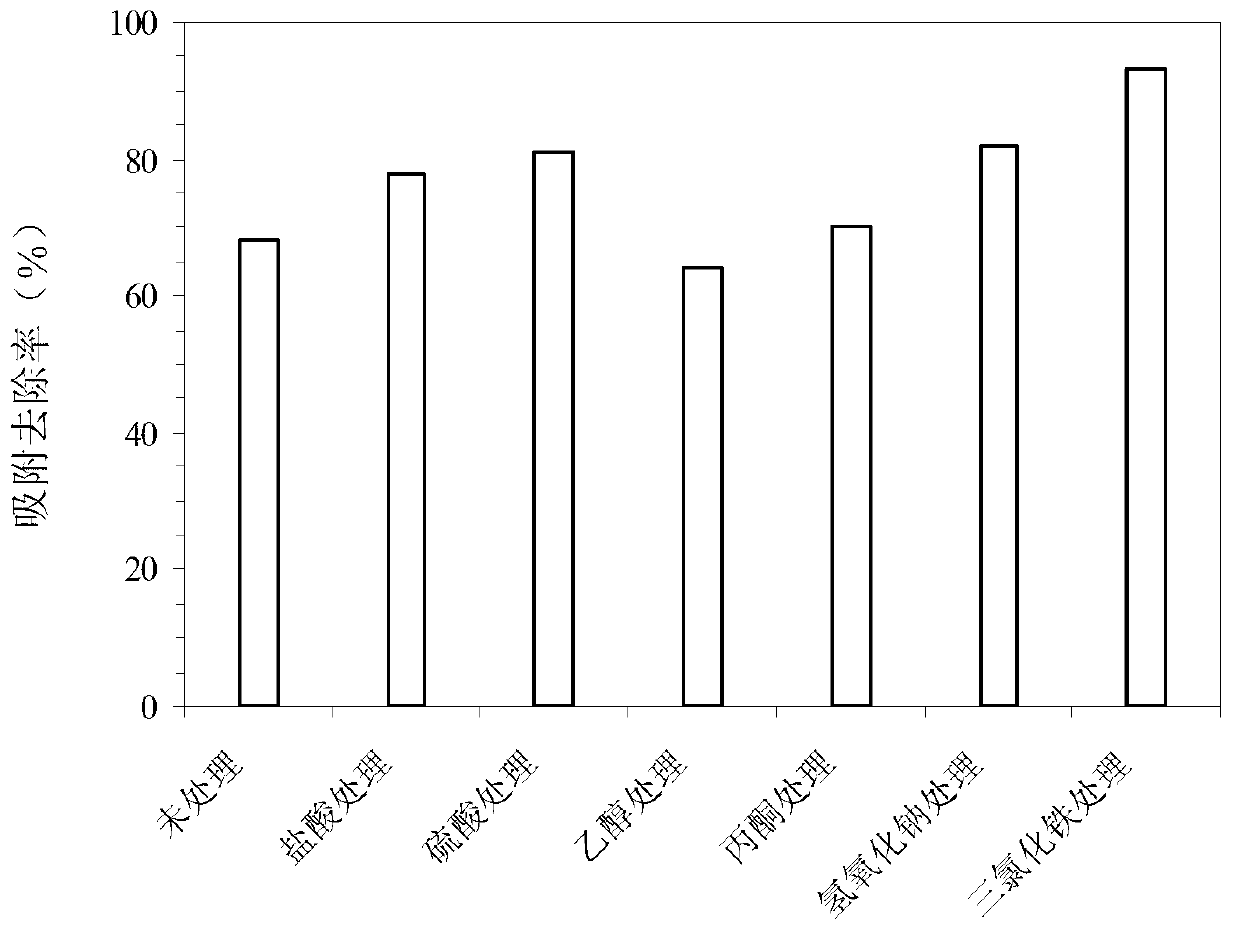

[0032] The influence of different traditional adsorbents on the adsorption capacity of volcanic rocks:

[0033] Such as figure 1 Shown: The volcanic rock is modified by traditional adsorbent treatment processes such as hydrochloric acid, sulfuric acid, ethanol, acetone, sodium hydroxide, and ferric chloride. The shaker is shaken for 12 hours, and then washed until the effluent is nearly neutral. Dry at 105℃; add 4g of modified volcanic stone adsorbent to 500mL mercury-containing wastewater with an initial concentration of 0.5mg / L, shake the shaker for 1h, and the pH of the water body is 10.86. From figure 1 It can be seen that the adsorption rate of mercury on the modified volcanic stone adsorbent is greatly affected by the modification conditions, and the modified volcanic stone has the highest adsorption rate after treatment with ferric chloride.

Embodiment 2

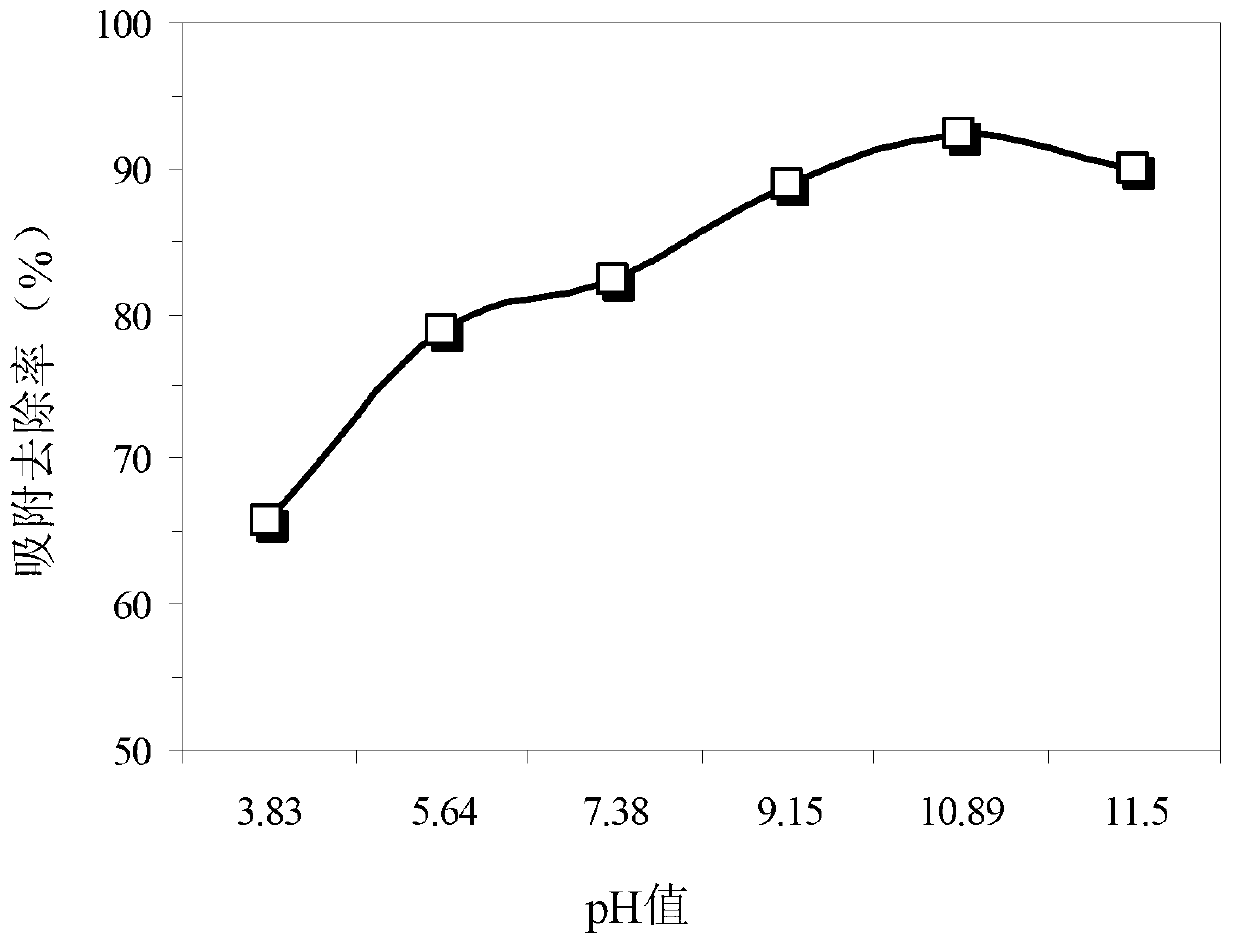

[0035] The influence of different pH values on the adsorption capacity of modified volcanic rocks:

[0036] Such as figure 2 As shown, under the conditions of water pH of 3.83, 5.64, 7.38, 9.15, 10.89 and 11.5, 4g of modified volcanic sorbent was added to 500mL of mercury-containing wastewater with an initial concentration of 0.5mg / L. Oscillate for 1h. From figure 2 It can be seen that the mercury adsorption rate of the modified volcanic stone adsorbent is greatly affected by the pH change of the water body, and the adsorption rate is higher under alkaline conditions. When the water body pH ≈ 11, the modified volcanic stone has a greater effect on mercury. Adsorption capacity.

Embodiment 3

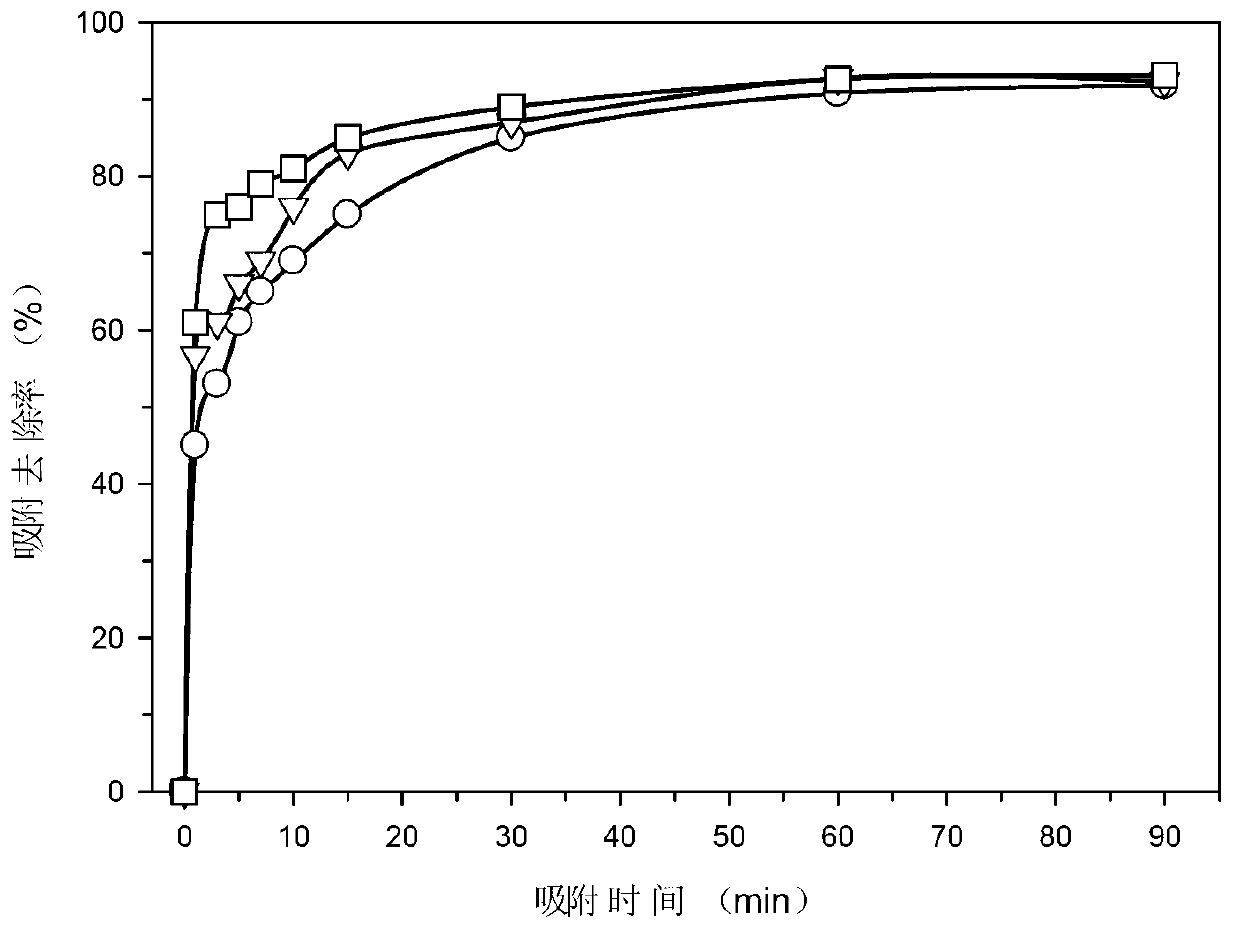

[0038] The effect of different dosages of modified volcanic adsorbents on adsorption performance:

[0039] Add 1g, 2g and 4g of modified volcanic stone adsorbent to 500mL mercury-containing wastewater with an initial concentration of 0.5mg / L and a pH of 10.89, and shake the shaker for 1h. image 3 "○" in the curve indicates that the dosage of modified volcanic stone adsorbent is 1g, which accounts for 0.2% of the mass percentage of mercury-containing waste water; "▽" indicates that the dosage of modified volcanic stone adsorbent is 2g, which is The mass percentage of mercury-containing waste water is 0.4%; "□" means that the dosage of modified volcanic stone adsorbent is 4g, which accounts for 0.8% of the mass percentage of mercury-containing waste water. It can be seen that the ratio of the dosage of modified volcanic rock to the quality of wastewater is in the range of 0.2-0.8%, and the adsorption rate does not change much, and can still reach more than 92%. At the same time, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com