Preparation method of nanometer manganese sesquioxide with a hollow cone shape

A technology of manganese trioxide and hollow circle is applied in the field of nanomaterials to achieve the effects of easy control, novel structure and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

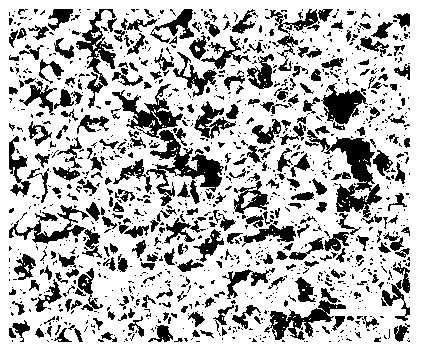

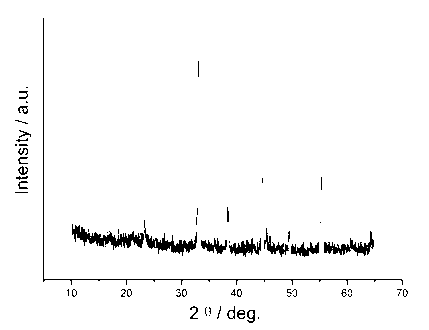

[0016] Dissolve 0.1g of P123 in 30ml of deionized water, then add 30mg of carbon nanotubes, after ultrasonic dispersion, add 4ml of 0.2mol / L manganese nitrate solution, stir, ultrasonically disperse for 2 hours, then add dropwise 10ml of 0.1mol / L manganese nitrate solution into the solution Potassium manganate solution, then the mixed solution was transferred to a 50ml hydrothermal kettle, hydrothermally reacted at a temperature of 130°C for 6h, and finally cooled to room temperature, suction filtered, washed, and dried at 60°C for 6h. What is obtained is a homogeneously doped manganese dioxide hollow nanocone / carbon nanotube composite material (scanning electron microscope photos such as figure 1 shown), the product was transferred to a tube furnace and calcined at 550 °C in air for 4 h. What is obtained is a high-purity nano-Mn with a hollow cone shape 2 o 3 , transmission electron microscope pictures as figure 2 As shown, the XRD curve is as image 3 shown.

Embodiment 2

[0018] Dissolve 0.1g of P123 in 30ml of deionized water, then add 60mg of carbon nanotubes, after ultrasonic dispersion, add 1ml of 0.6mol / L manganese nitrate solution, stir, ultrasonically disperse for 2 hours, then add 10ml dropwise to the solution with a concentration of 0.1mol / L Potassium permanganate solution, then the mixed solution was transferred to a 50ml hydrothermal kettle, hydrothermally reacted at a temperature of 120°C for 5h, and finally cooled to room temperature, suction filtered, washed, and dried at 60°C for 6h. The homogeneously doped manganese dioxide hollow nanocone / carbon nanotube composite material was obtained. The product was transferred to a tube furnace and calcined at 550° C. for 6 hours in air. What is obtained is a high-purity nano-Mn with a hollow cone shape 2 o 3 .

Embodiment 3

[0020] Dissolve 0.1g of P123 in 30ml of deionized water, then add 30mg of activated carbon, after ultrasonic dispersion, add 1.5ml of 0.5mol / L manganese nitrate solution, stir, ultrasonically disperse for 2 hours, then add dropwise 10ml of 0.1mol / L permanganese into the solution Potassium acid potassium solution, then the mixed solution was transferred to a 50ml hydrothermal kettle, hydrothermally reacted at a temperature of 120°C for 6h, and finally cooled to room temperature, suction filtered, washed, and dried at 60°C for 6h. The homogeneously doped manganese dioxide hollow nanocone / activated carbon composite material was obtained. The product was transferred to a tube furnace and calcined at 550°C for 2 hours in air. What is obtained is a high-purity nano-Mn with a hollow cone shape 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com