Method for preparation of super long fibrous titanium dioxide by taking cellulosic fibers as template

A cellulose fiber and titanium dioxide technology, which is applied in fiber processing, textiles and papermaking, etc., can solve the problems of difficulty in reaching the length of fibrous materials, complicated processes, and single source, and achieve the effects of low cost, wide source of raw materials, and uniform diameter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

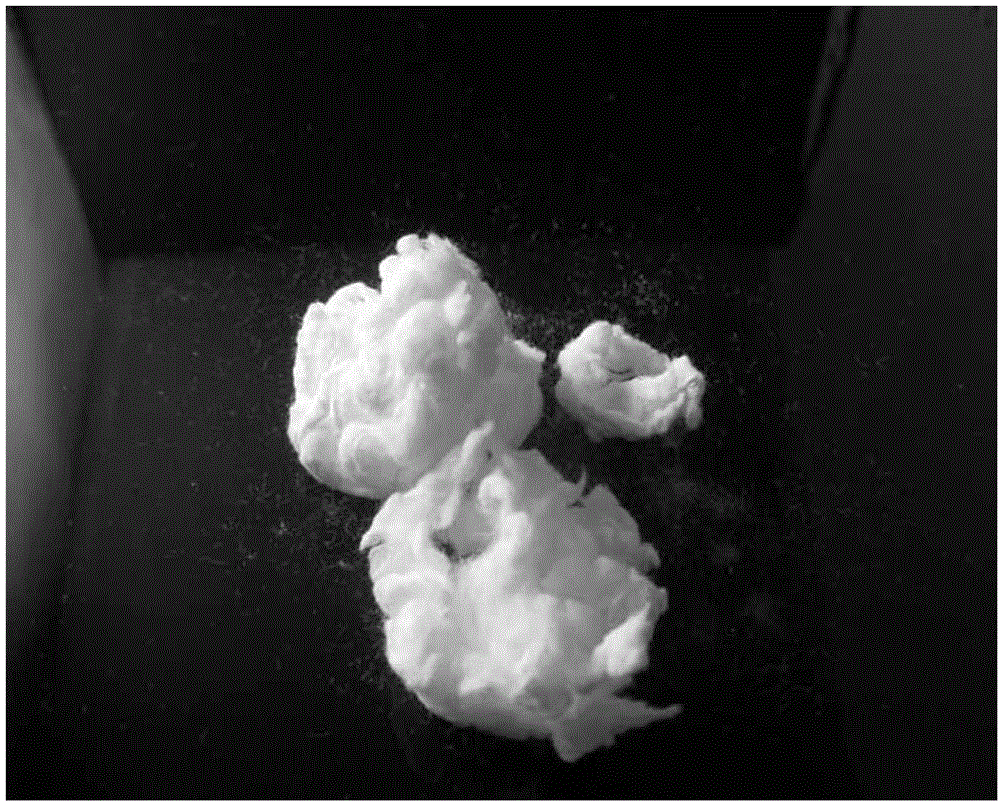

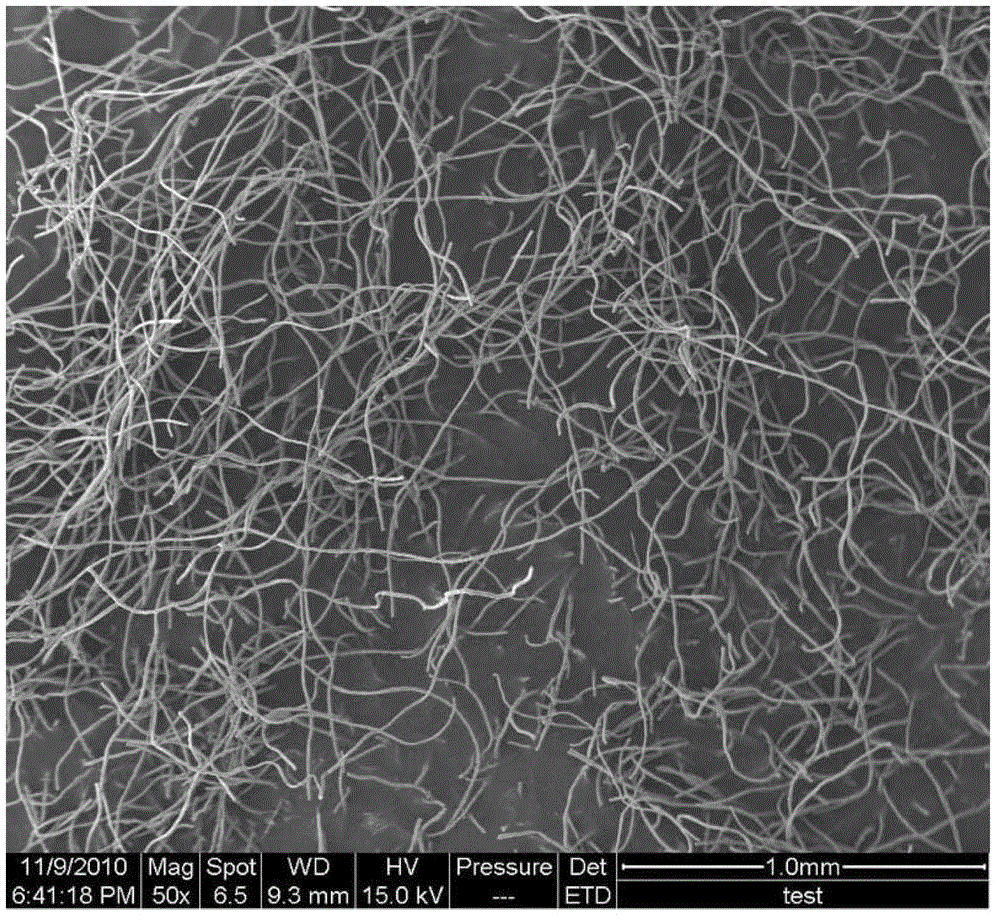

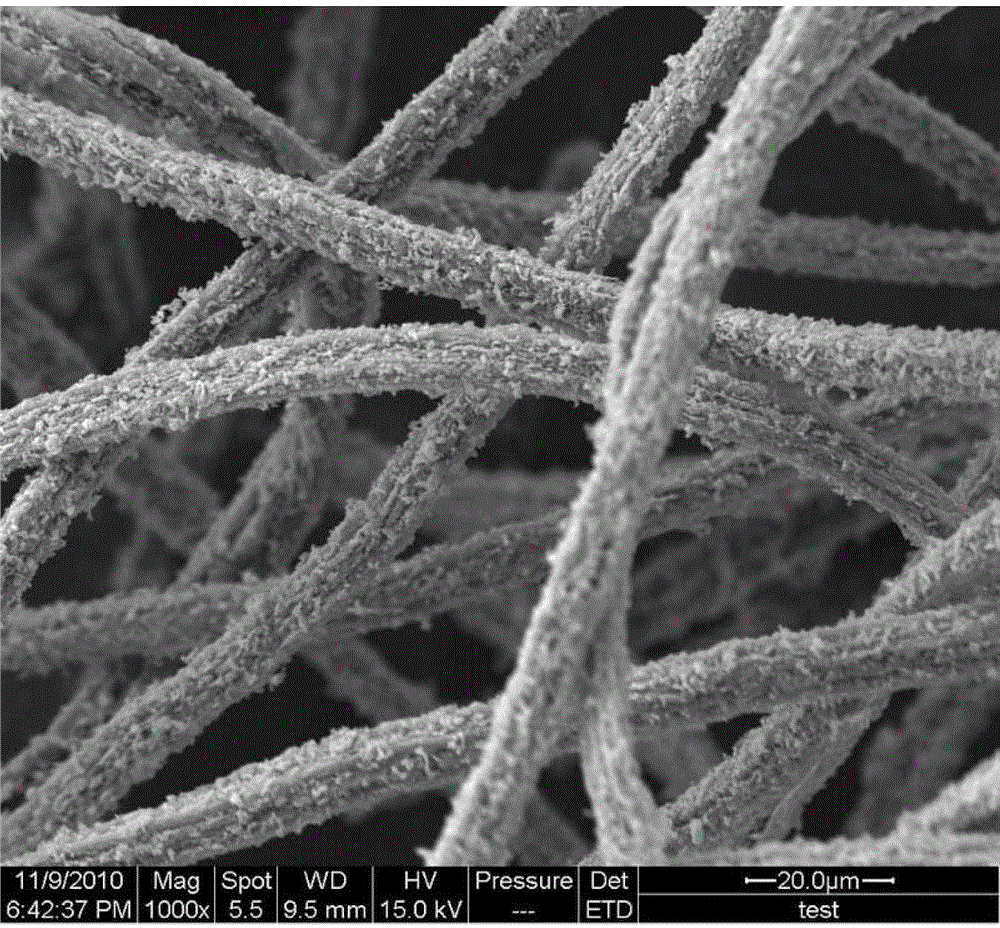

[0023] Specific Embodiment 1: In this embodiment, a method for preparing ultra-long fibrous titanium dioxide using cellulose fibers as a template is carried out through the following steps: 1. After cleaning and drying the natural fibers, disperse them in deionized water to obtain natural Fiber dispersion; Wherein, natural fiber is the fiber of cotton, hemp, wool, silk or bamboo;

[0024] 2. Add titanium tetrachloride to the natural fiber dispersion obtained in step 1, and stir magnetically for 0.5 to 2 hours at a stirring rate of 50r / min to 300r / min under ice-water bath conditions to obtain TiOH attached 3+ Dispersions of natural fibers;

[0025] 3. Under the condition of ice-water bath, attach TiOH to the obtained step 2 3+ Add (NH 4 ) 2 SO 4 and HCl solution with a mass percentage of 1% to 3%, and then magnetically stirred at a stirring rate of 50r / min to 300r / min for 0.5 to 2h, and then heated and stirred to obtain TiOSO attached 4 Dispersions of natural fibers;

[0...

specific Embodiment approach 2

[0034] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the length of the natural fiber described in step 1 is millimeter or centimeter level, and the fiber of cotton, linen, wool, silk and bamboo with a diameter of 5-50 μm . Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the cleaning in step 1 refers to using water or absolute ethanol to clean the surface of the natural fiber. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com