Thin film solar cell bus bar intersection automatic hot welding device

A technology of thin-film solar cells and intersections, which is applied in the direction of tin feeding devices, auxiliary devices, welding equipment, etc., can solve the problems of high cost, easy to fall off, and weak welding points, and achieve fast welding speed, high welding quality, and avoid The effect of inconsistent weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] In order to more fully explain the implementation of the present invention, the implementation examples of the present invention are provided, and these implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention. The invention is especially suitable for the confluence intersection formed by the automatic thermal welding of thin film solar cells, where the vertical strips used for confluence are copper-aluminum strips, and the horizontal strips connected to the junction box are tinned copper strips.

[0008]

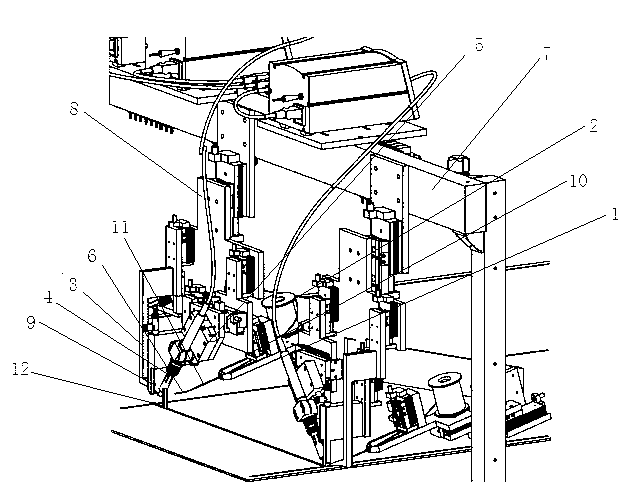

[0009] The assembly process of this device is as follows: figure 1 As shown, a gantry 7 is arranged above the transmission positioning mechanism, and a total lifting slide 8 driven by a linear drive mechanism, a linear drive mechanism of the wire feeding slide 1, a linear drive mechanism of the welding presser foot 3, and a welding gun are arranged on the gantry 7. The linear drive mechanisms of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com