Control device for internal combustion engine

A technology for a control device and an internal combustion engine, applied in engine control, internal combustion piston engine, electrical control, etc., can solve problems such as catalyst surface area reduction and catalyst degradation, and achieve the effects of improving acceleration responsiveness, inhibiting degradation, and reducing heat gain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0042] [System Configuration of Embodiment 1]

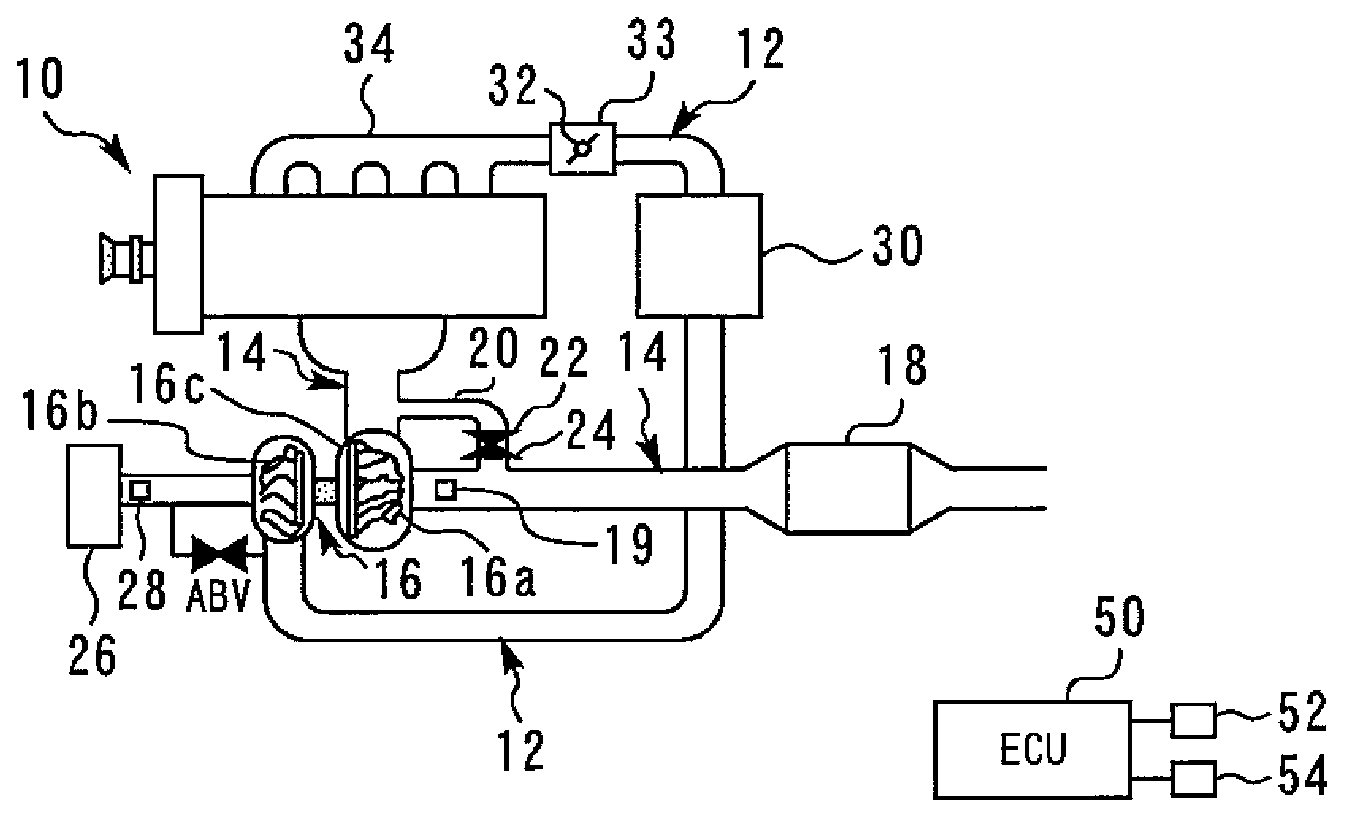

[0043] figure 1 It is a figure for demonstrating the system structure of Embodiment 1 of this invention. figure 1 The system shown has an internal combustion engine 10 . The internal combustion engine 10 is mounted on a vehicle and serves as a power source of the vehicle. figure 1 The illustrated internal combustion engine 10 has more than one cylinder.

[0044] An intake passage 12 and an exhaust passage 14 are connected to each cylinder of the internal combustion engine 10 . An intake valve (not shown) that opens and closes between the inside of the cylinder and the intake passage 12 is provided at the downstream end of the intake passage 12 . Similarly, an exhaust valve (not shown) that opens and closes between the inside of the cylinder and the exhaust passage 14 is provided at an upstream end of the exhaust passage 14 .

[0045] Exhaust gas discharged from each cylinder of the internal combustion engine 10 flows into an...

Embodiment approach 2

[0078] [System Configuration of Embodiment 2]

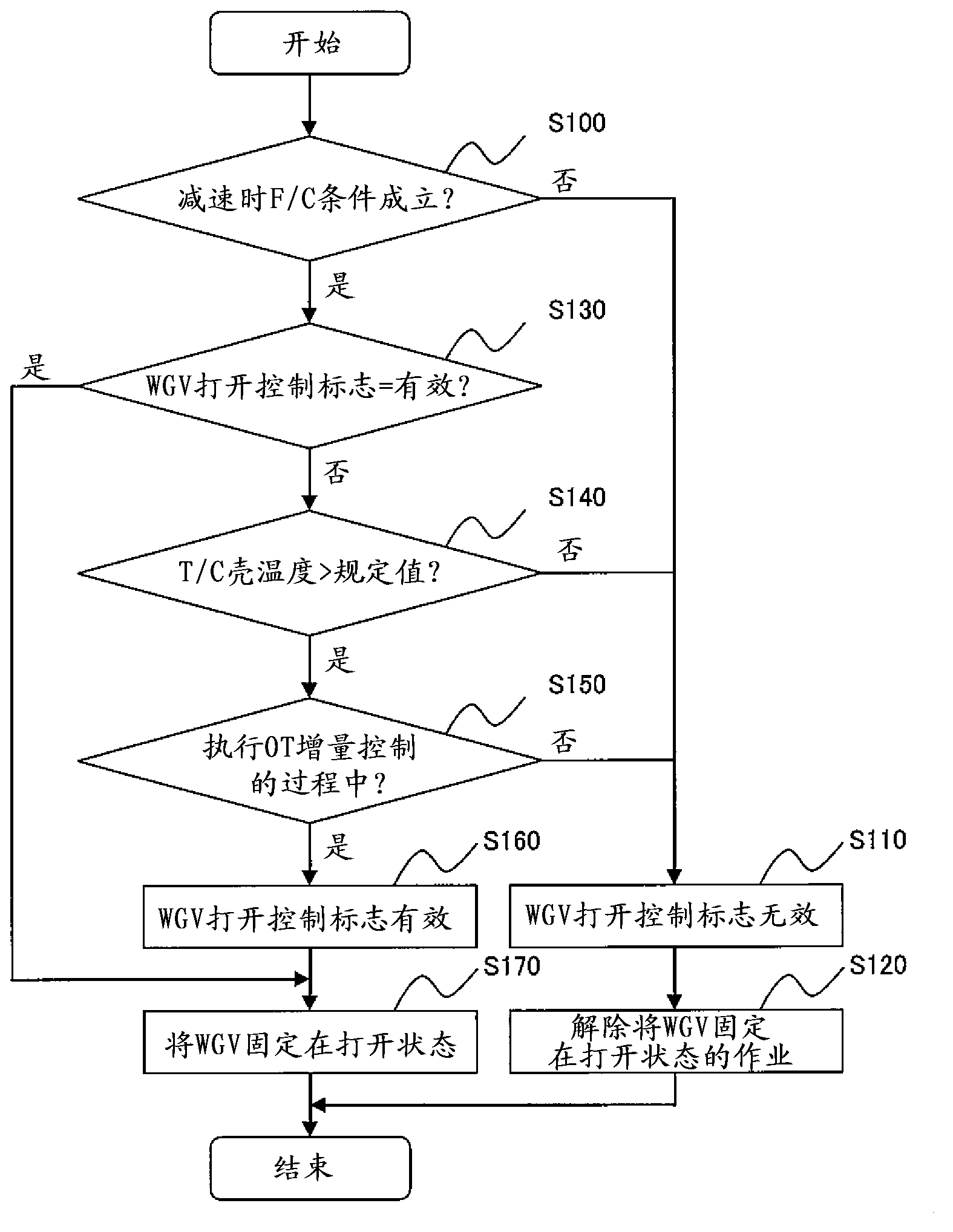

[0079] Next, refer to Figure 4 Embodiment 2 of the present invention will be described. The system of this embodiment adopts the figure 1 In the structure shown, ECU50 implements the following Figure 4 program to achieve.

[0080] [Characteristic Control in Embodiment 2]

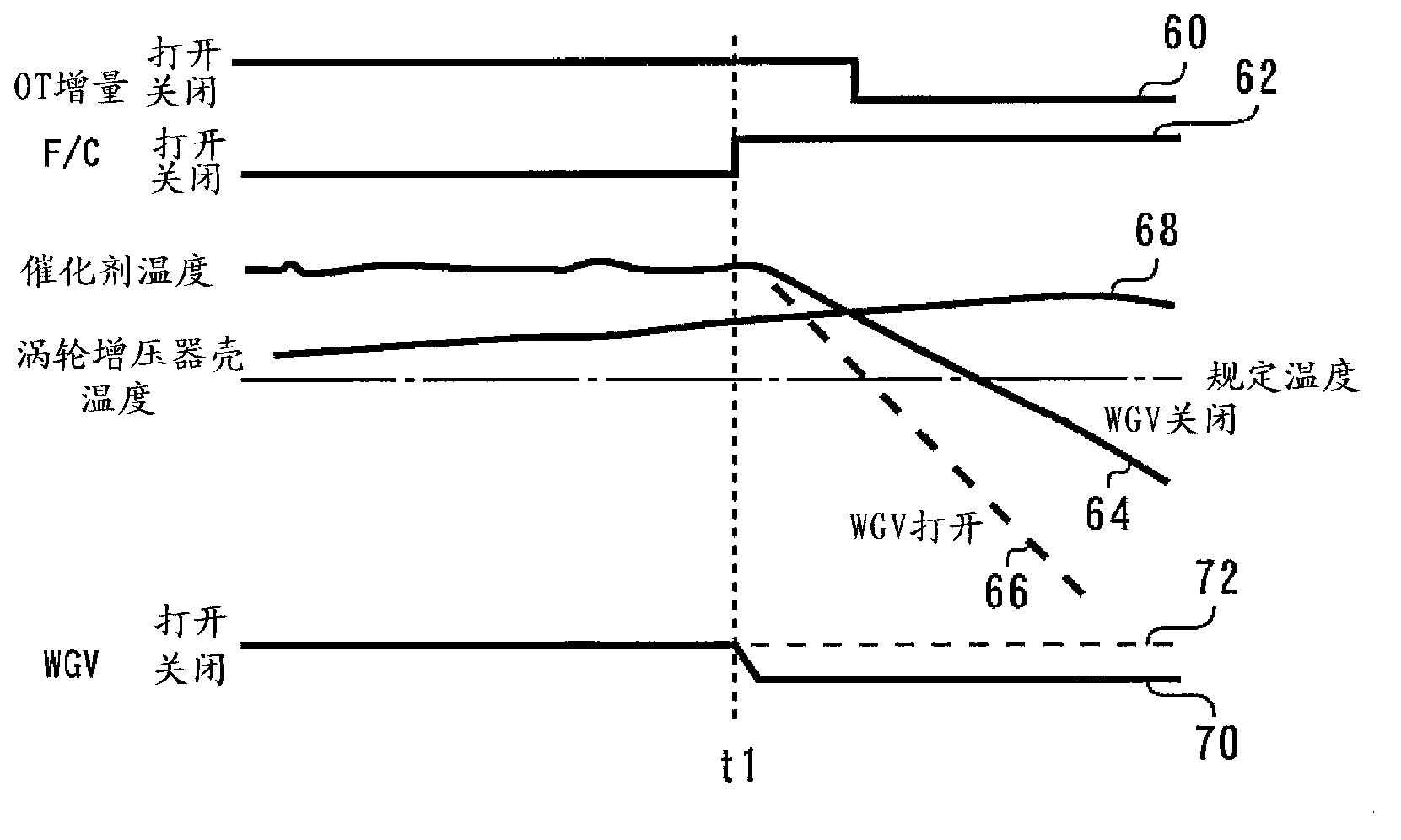

[0081] In Embodiment 1 described above, when the deceleration stop is performed, the wastegate valve 22 is fixed in the open state under predetermined conditions, thereby suppressing the deterioration of the catalyst 18 . However, after passing image 3 In the case where the shown control routine fixes the wastegate valve 22 in the open state, there may be cases where the driver depresses the accelerator to cause an acceleration request. In this case, good acceleration responsiveness is required. On the other hand, there are cases where the temperature of the scroll case is not a high temperature. Therefore, it is desired to be able to suppress the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com