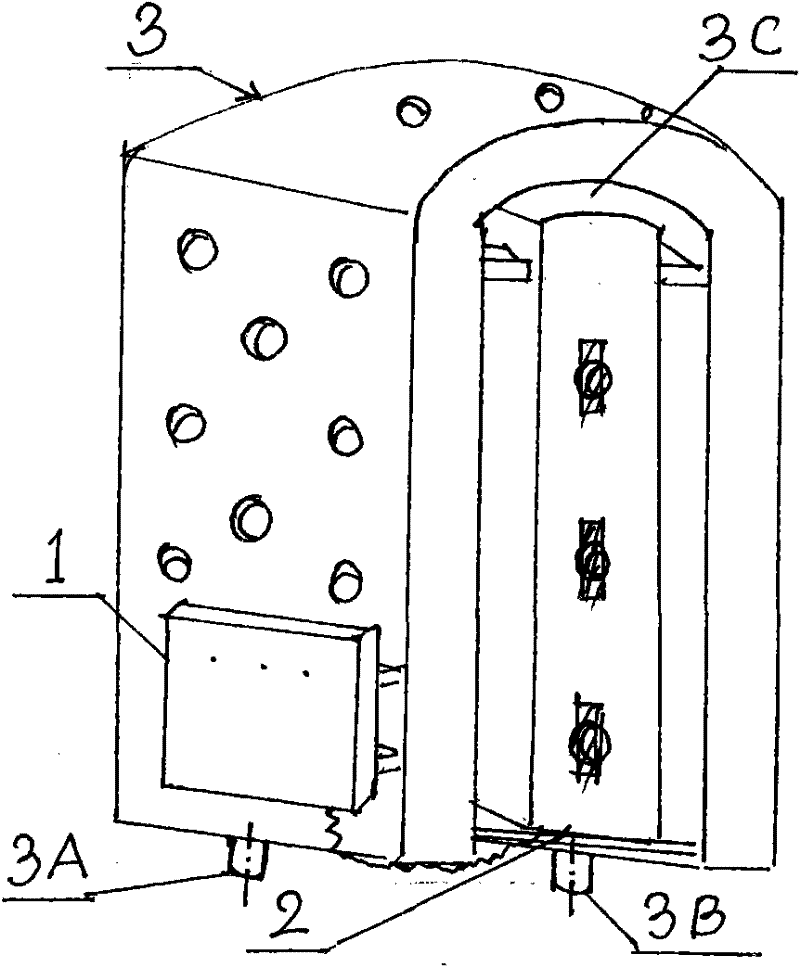

Electromagnetic type water heater and electromagnetic resistance dual-core water heater

A water heater, electromagnetic technology, used in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of increasing energy consumption, reducing electromagnetic heat efficiency, difficult to dissipate heat, etc., to achieve high hot water temperature and hot water. Yield, solve the effect of overheating damage, improve heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

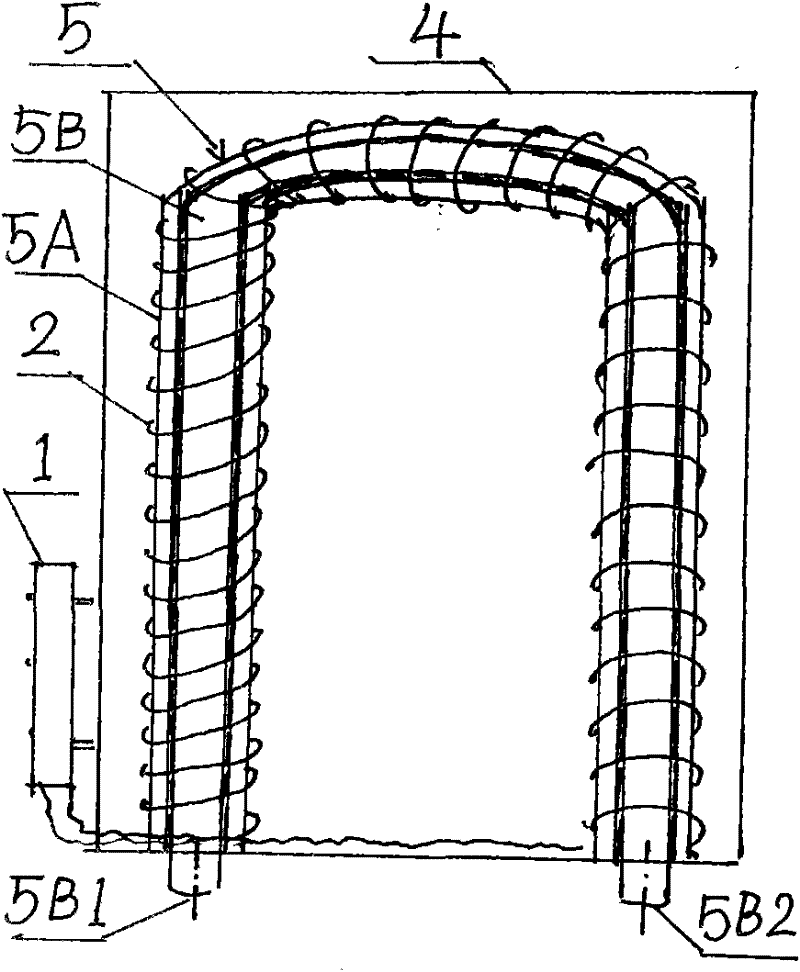

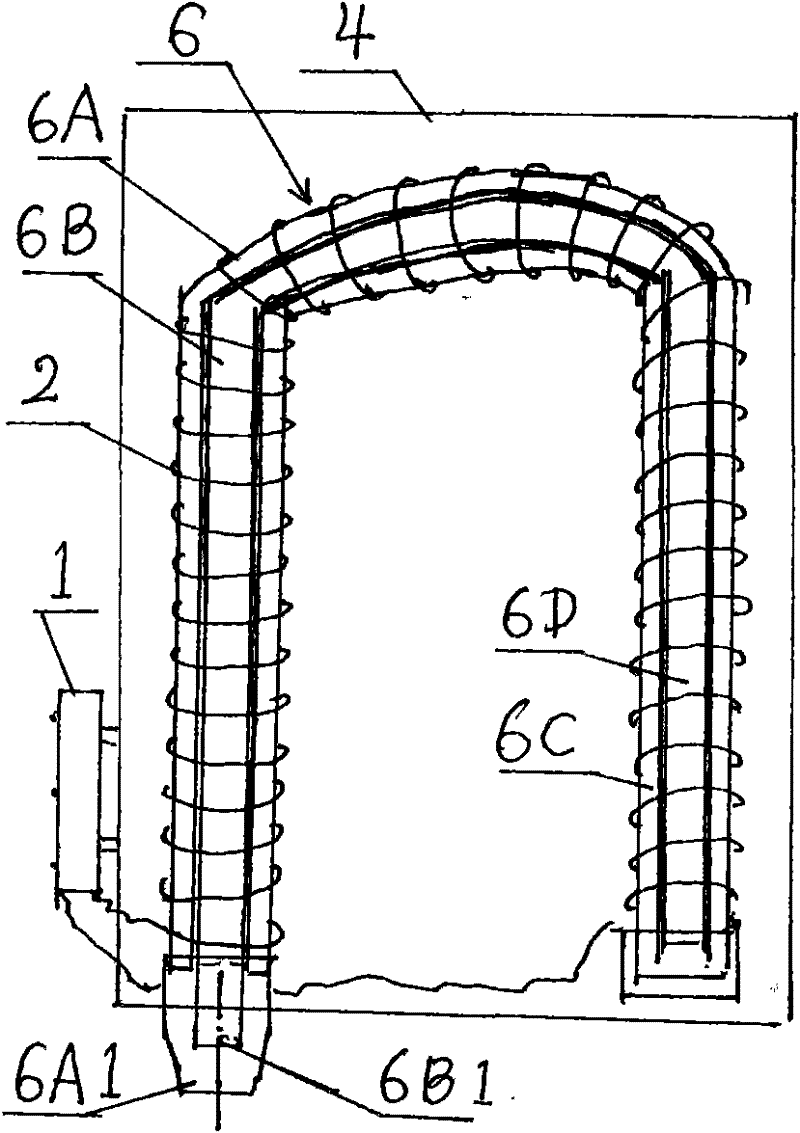

[0016] Some of the structural names and noun terms described in this application document are self-defining terms. Such as "integrated controller", which is an integrator composed of various detection circuits, control and display circuits, stable protection circuits, high-frequency power tubes, ICs and other components, because it is already an existing technology, such as the current There are the same or similar parts in the induction cooker, and because it is not the innovation point of the present invention, it is not necessary to split its structural composition and its respective functions and action processes and effects in detail to make complex expressions respectively, so it is given It is an integrated general name of an attributive; another example is "double-wall magnetically conductive water body" and "single water cavity casing magnetically conductive water body" and "double water cavity casing magnetically conductive water body", which are also based on them T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com