Assemble type multifunctional outer wall body and production and installation method thereof

A multi-functional, prefabricated technology, applied in the direction of walls, building components, ceramic molding machines, etc., can solve the problems of high building energy consumption, high construction cost, large resource consumption, etc., and achieve obvious economic benefits, good thermal insulation performance, fire performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

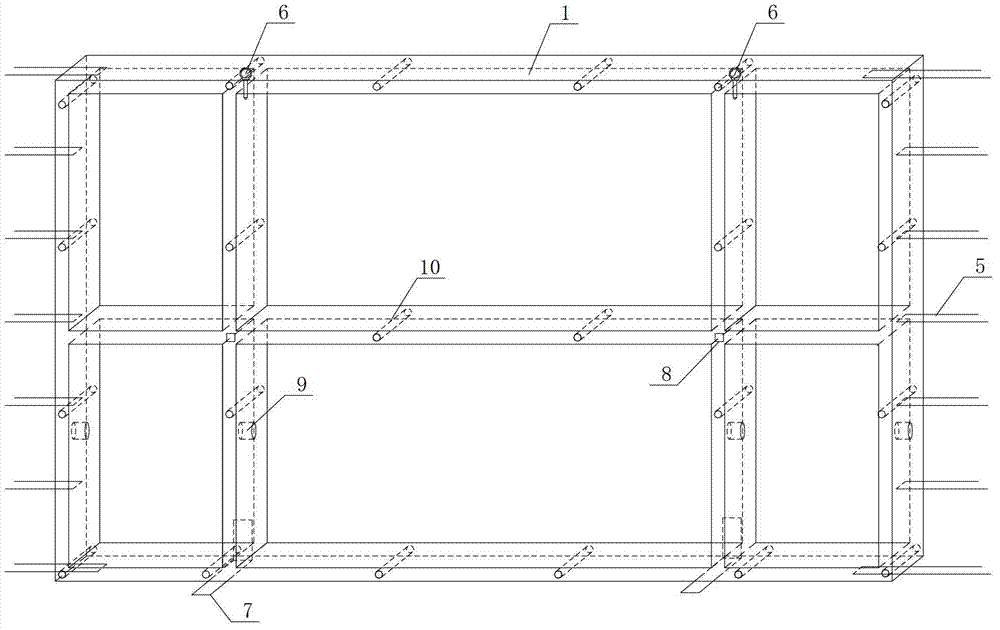

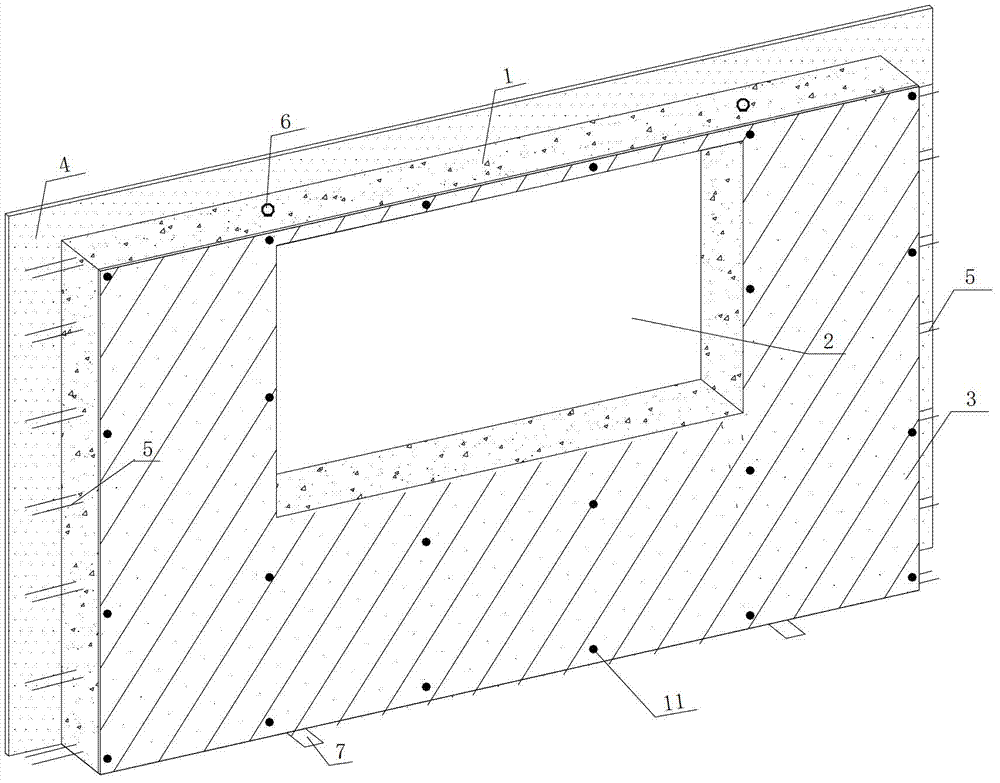

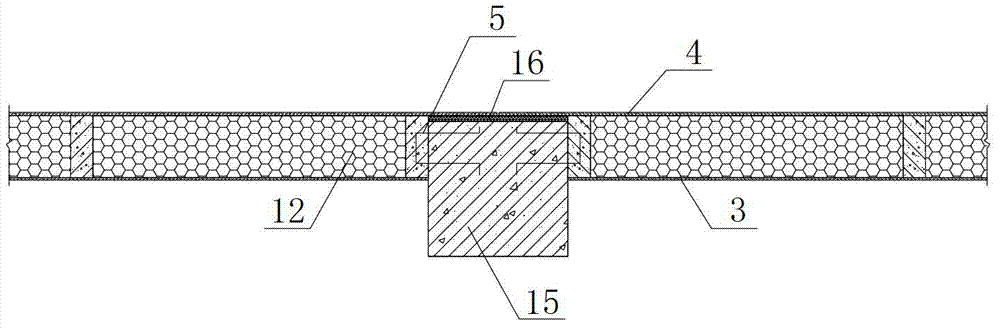

[0020] like Figure 1-2 The prefabricated multifunctional exterior wall shown is a frame sandwich composite structure, with a fine stone reinforced concrete frame 1 as the keel, the frame lattice is filled with foam concrete 12 and a window hole 2 is left, and the fine stone reinforced concrete frame , The cement fiber panels 3 and 4 are fixedly installed on the outside, and the cement fiber panels are provided with a decorative layer. Described foam concrete is the foam concrete poured on site or the prefabricated foam concrete insulation board, and the bulk density of foam concrete is 200-700kg / m 3 .

[0021] The fine stone reinforced concrete frame is a prefabricated integral reinforced concrete structure, the left and right sides of the fine stone reinforced concrete frame are embedded with tie bars 5, the top is embedded with lifting rings 6,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com