Preparation method of novel modified furan resin for casting

A furan resin and modification technology, which is applied in casting molding equipment, casting molds, cores, etc., can solve the problems of unsuitable wood adhesives, etc., and achieve the effects of good stability and transparency, high tensile strength, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 30g of water, 100g of sucrose and 0.1g of urea into the reaction vessel, stir at 10°C until dissolved, then add 5g of concentrated sulfuric acid, stir and heat up to 60°C, react for 20h, cool down to 30°C; use 30% hydrogen to oxidize Adjust the pH value to 7.5 with sodium, add 0.1 g of formaldehyde, raise the temperature at 60°C for 6 hours, and then dehydrate 5 g to obtain a brown-red viscous liquid.

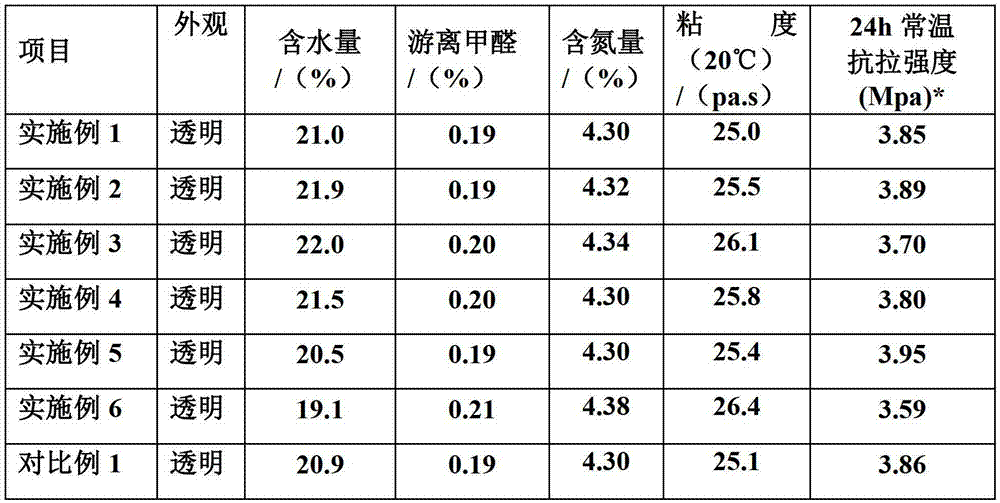

[0036] According to the corresponding steps of the comparative example, under the conditions of steps (1) to (3) unchanged, in step (4), take 5 g of the above-mentioned brown-red viscous liquid to replace 5 g of furfuryl alcohol in step (4) of the comparative example (the total amount of raw materials 5% by weight), the raw materials actually participating in the reaction are 35g furfuryl alcohol, 5g brownish-red viscous liquid and 0.85g silane coupling agent, and other conditions remain unchanged to obtain a modified furan resin for casting, and its properties are sh...

Embodiment 2

[0038] Add 60g of water, 100g of glucose and 5g of urea into the reaction vessel, stir at 30°C until dissolved, then add 10g of concentrated nitric acid, stir and raise the temperature to 80°C, react for 4 hours, and cool down to 40°C; use 30% sodium hydroxide Adjust the pH value to 8.5, add 6g of formaldehyde, heat up to 70°C for 4 hours, and then dehydrate 80g to obtain a brown-red viscous liquid.

[0039] According to the corresponding steps of the comparative example, under the conditions of steps (1) to (3) unchanged, in step (4), take 5 g of the above-mentioned brown-red viscous liquid to replace 10 g of furfuryl alcohol in the step (4) of the comparative example (the total amount of raw materials 10% by weight), the actual raw materials that participated in the reaction were 30g furfuryl alcohol, 10g brownish-red viscous liquid and 0.85g silane coupling agent, and other conditions were unchanged to obtain a modified furan resin for casting, and its properties are shown i...

Embodiment 3

[0041] Add 76g of water, 100g of sucrose and 7.5g of urea into the reaction vessel, stir at 40°C until dissolved, then add 25g of concentrated hydrochloric acid, stir and raise the temperature to 84°C, react for 2 hours, then cool down to 50°C; adjust with 20% ammonia water When the pH value reached 8.5, 8g of formaldehyde was added, the temperature was raised to 95°C for 1 hour, and then 98g was dehydrated to obtain a brown-red viscous liquid.

[0042] According to the corresponding steps of the comparative example, under the condition that steps (1) to (3) remain unchanged, in step (4), take 20 g of the above-mentioned brown-red viscous liquid to replace 20 g of furfuryl alcohol in step (4) of the comparative example (the total amount of raw materials 20% by weight), the raw materials actually participating in the reaction are 20g furfuryl alcohol, 20g brownish-red viscous liquid and 0.85g silane coupling agent, and other conditions remain unchanged to obtain a modified furan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com