Automatic powder material feeding method and device

An automatic feeding and powder technology, applied in the direction of mixing methods, chemical instruments and methods, dissolution, etc., can solve the problems of difficult mixing, high labor intensity, low work efficiency, etc., to reduce environmental pollution, high solid content, Good effect of optimizing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

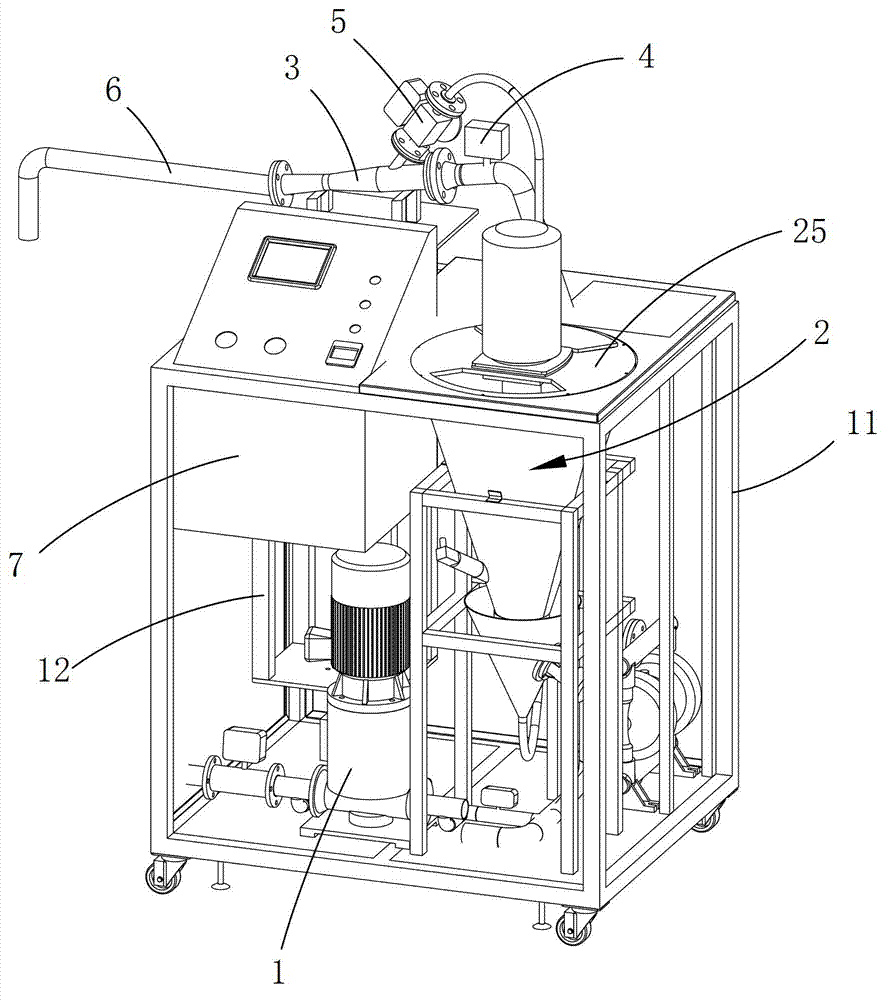

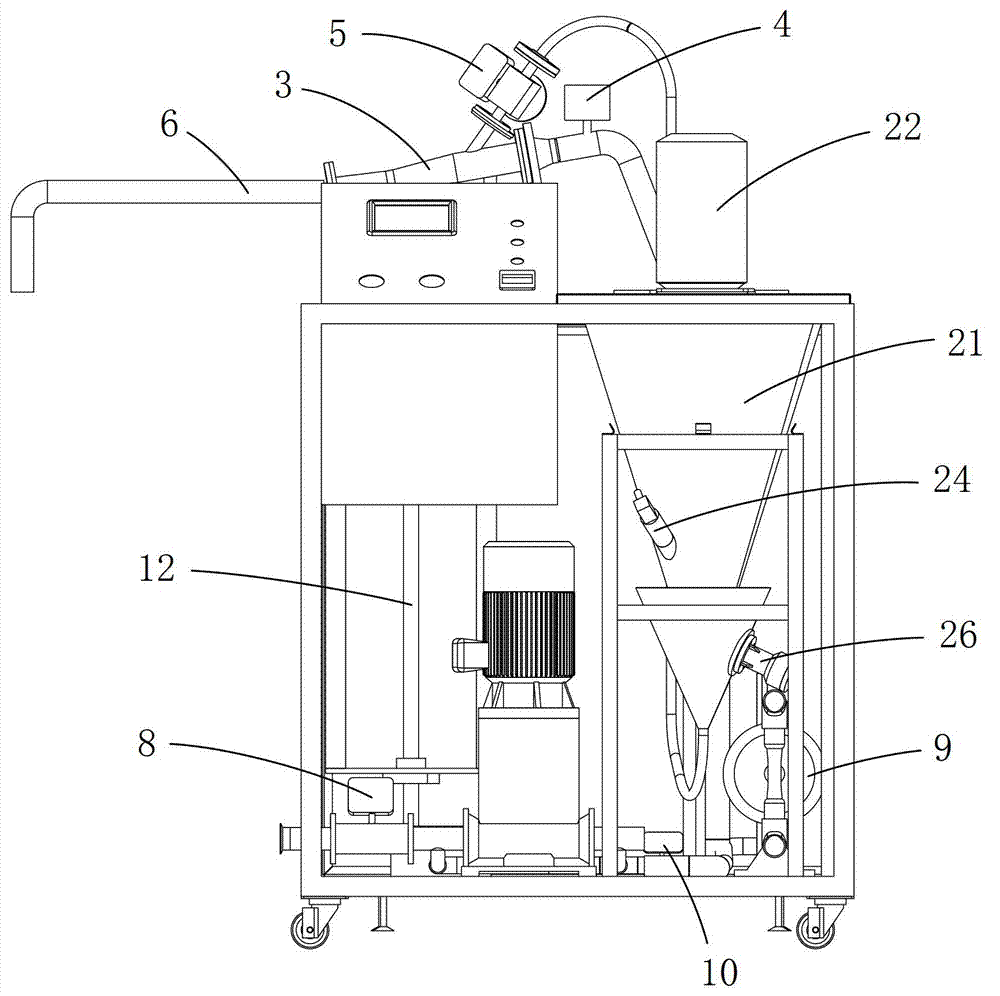

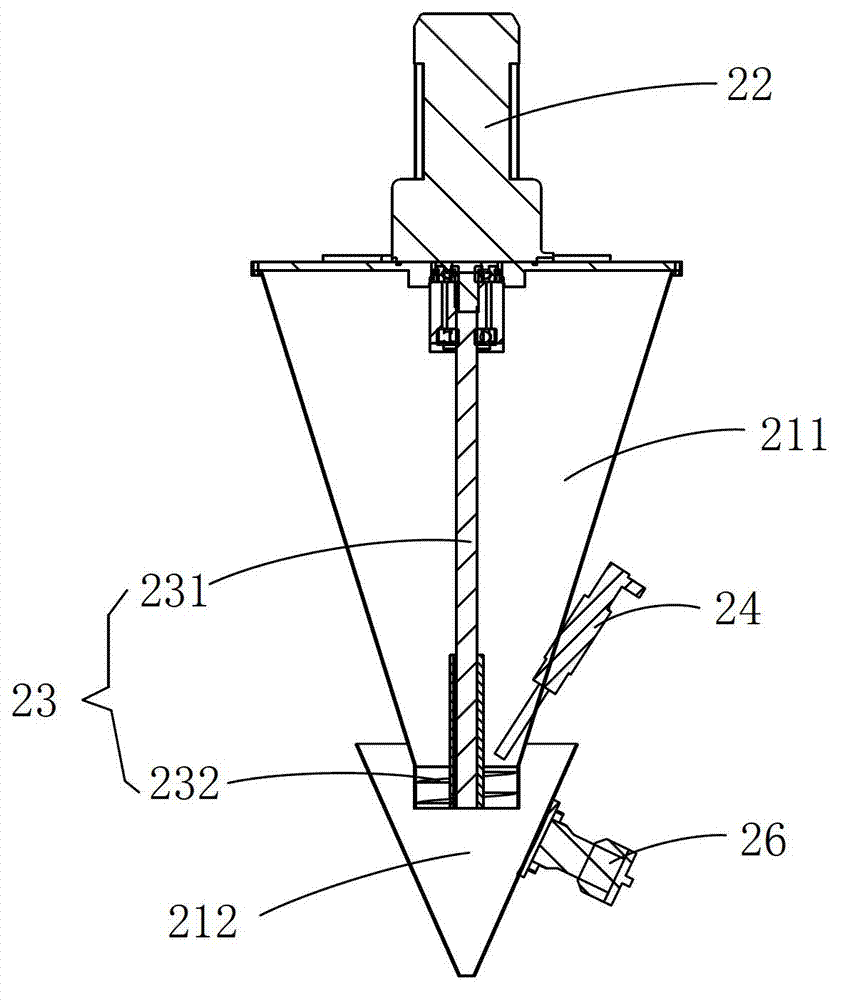

[0034] See Figure 1 to Figure 3 , a kind of powder material automatic feeding method provided by the present invention, it comprises the following steps:

[0035] 1) Set up a mixing mechanism to realize the mixing of powder and liquid; the mixing mechanism is a venturi tube 3, one end of which is provided with a mixture outlet, the other end is provided with a liquid inlet and a powder inlet The feed port; the mixture discharge port outputs the mixed material mixed through the Venturi tube 3 into the dissolution tank, and the liquid feed port and the powder feed port are all provided with pressure and flow control devices; The feeding mechanism also includes a compressed air source. The pressure and flow control device provided at the powder feeding port is a three-way pneumatic valve 5, and the powder feeding port is respectively connected with the powder through the three-way pneumatic valve 5. The conveying mechanism is connected with the compressed air source to control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com