Light-emitting diode (LED) packaging structure

A technology of LED packaging and LED chips, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high thermal resistance TG point, unfavorable stability of device heat dissipation and physical characteristics, complex structure, etc., to achieve efficient heat dissipation and efficient heat dissipation The effect of cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

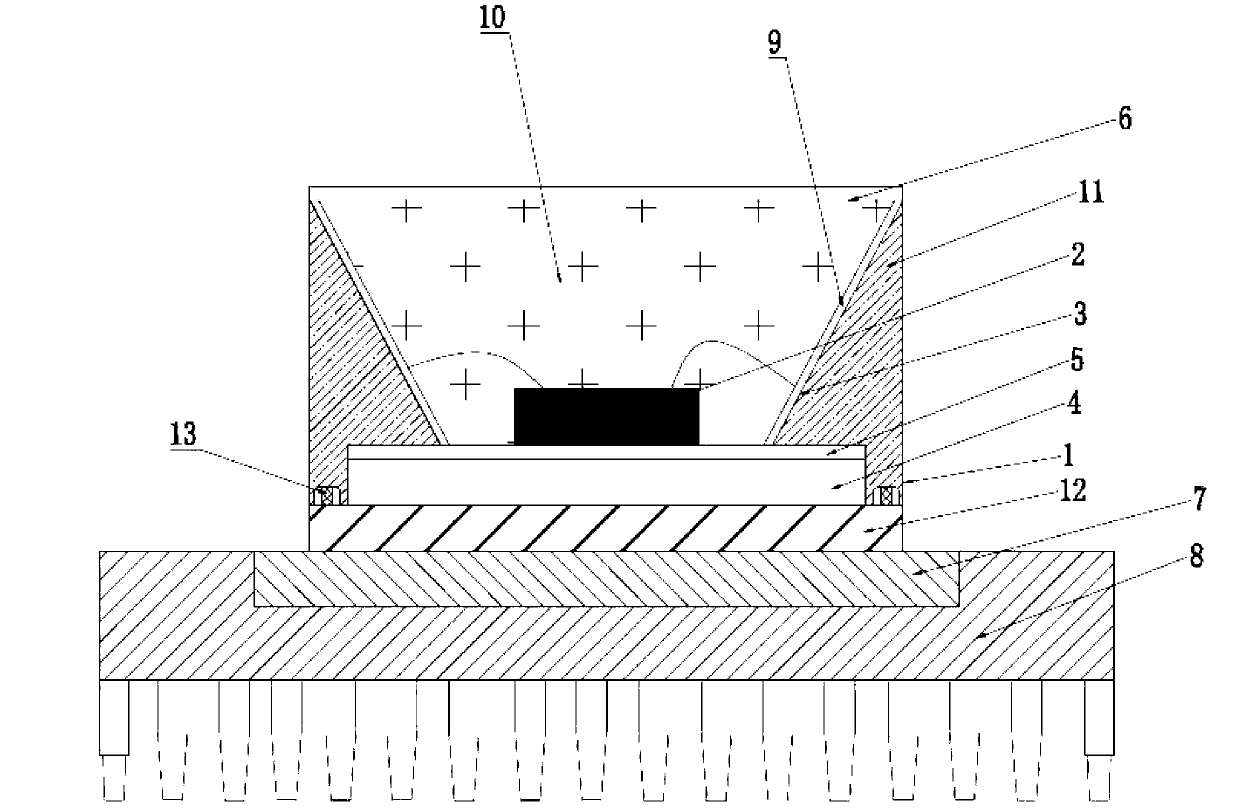

[0021] Such as figure 1 As shown, an LED packaging structure includes a packaging substrate 1 and a light-emitting LED chip 2. The packaging substrate 1 has at least one groove-shaped reflective cup 3, the LED chip 2 is mounted on the packaging substrate 1, and the light-emitting LED A thermally conductive substrate 4 is arranged between the chip 2 and the packaging substrate 1, the thermally conductive substrate 3 uses a silver base as a thermal lining material, and the thermally conductive substrate is welded to the packaging substrate through a tin sheet 5.

[0022] The upper end of the reflecting cup is provided with a lens 6, the lens 5 and the reflecting cup 3 form a sealed cavity, and the lens is a glass sheet containing phosphor. By arranging a focusing lens on the surface of the LED chip and placing the phosphor-containing glass sheet at a certain distance from the wafer, not only the reliability of the device is improved, but also the light efficiency is greatly improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com