Photoresist removal method and semiconductor production method

A technology of photoresist and deionized water, applied in semiconductor/solid-state device manufacturing, photosensitive material processing, electrical components, etc. Solve problems such as bottom silicon, achieve the effect of reducing photoresist residues, ensuring quality, and improving deglue efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

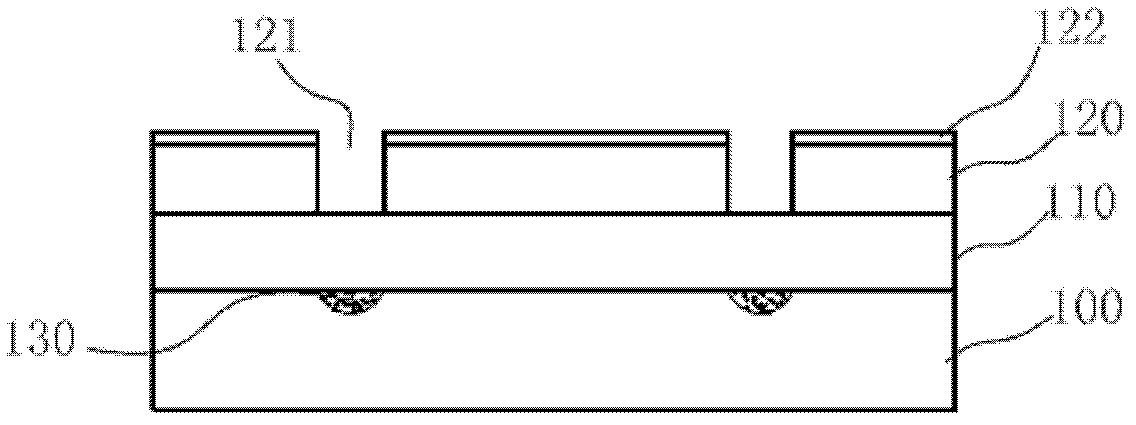

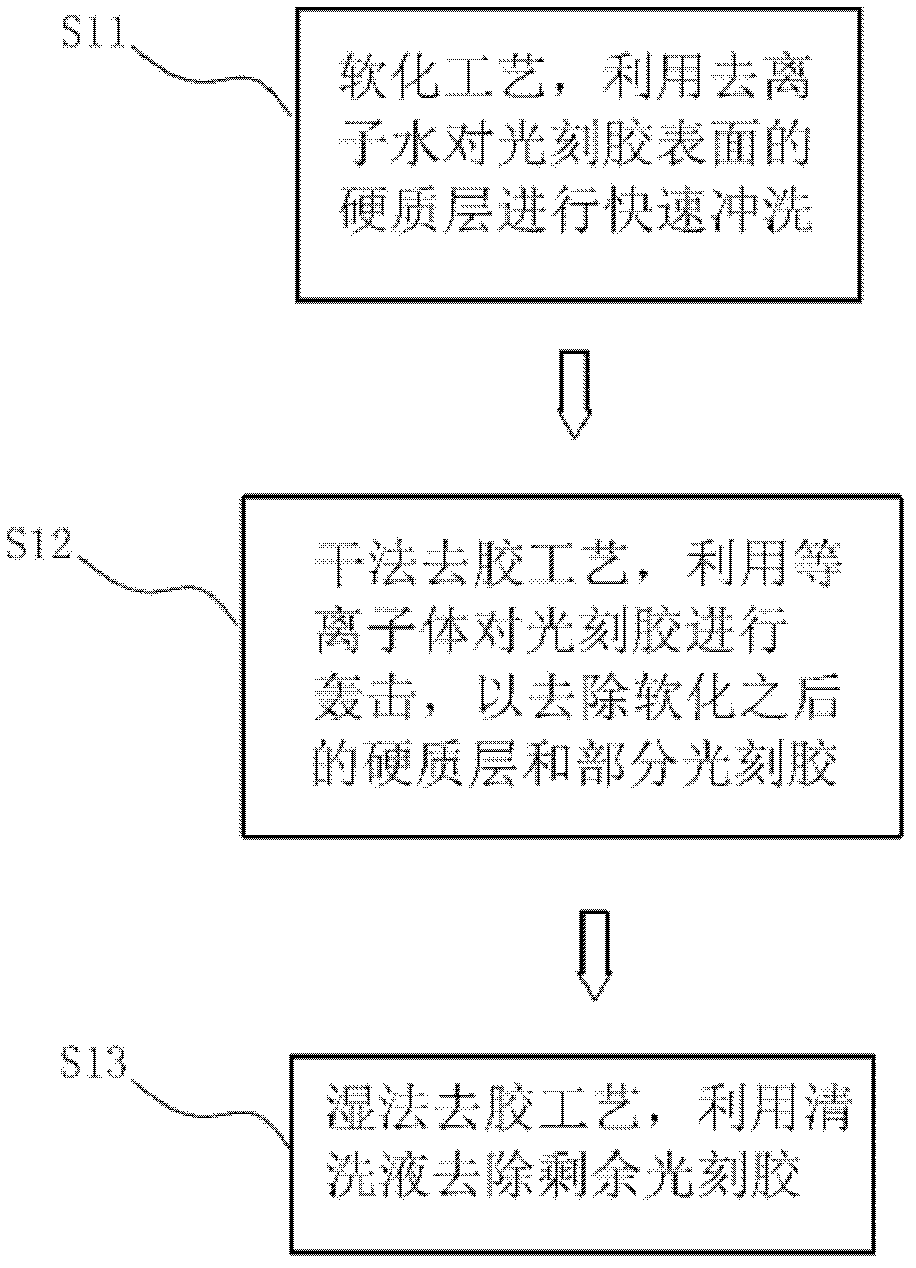

[0034] As mentioned in the background art, after the ion implantation process of the photoresist, a hard layer is formed due to the reaction of the surface with high-energy ions. The hard layer brings difficulties to the stripping process of the photoresist. In the existing degumming process, the plasma dry degumming process can remove part of the hard layer, but the plasma energy used is relatively large. When facing a process below 65nm, it is easy to damage the oxide layer as a buffer layer , thereby damaging the silicon substrate surface. However, the wet stripping process is difficult to effectively remove the hard layer, resulting in residual defects in the photoresist and affecting the quality of the device.

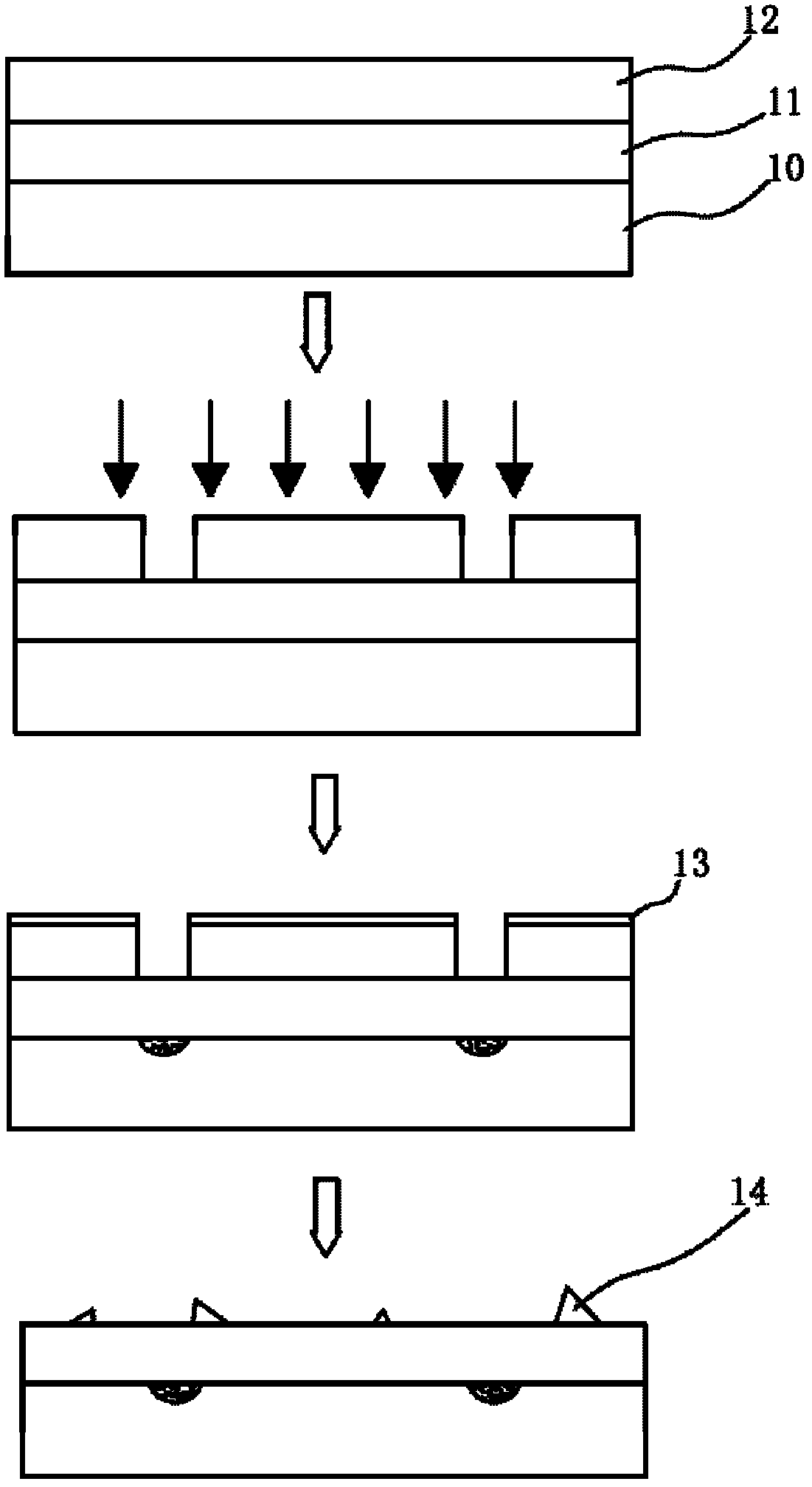

[0035] Therefore, the present invention proposes a method for removing the photoresist mask after the ion implantation process is performed using the photoresist as a mask during the manufacturing process of the semiconductor device.

[0036] See figure 2 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com