Special release agent for concrete and preparation method thereof

A release agent, concrete technology, applied in the direction of additives, manufacturing tools, petroleum industry, etc., can solve the problems of emulsifier or solvent, inconvenient storage, increase storage cost and transportation cost, etc., to achieve easy demoulding and convenient storage , the effect of wide storage temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

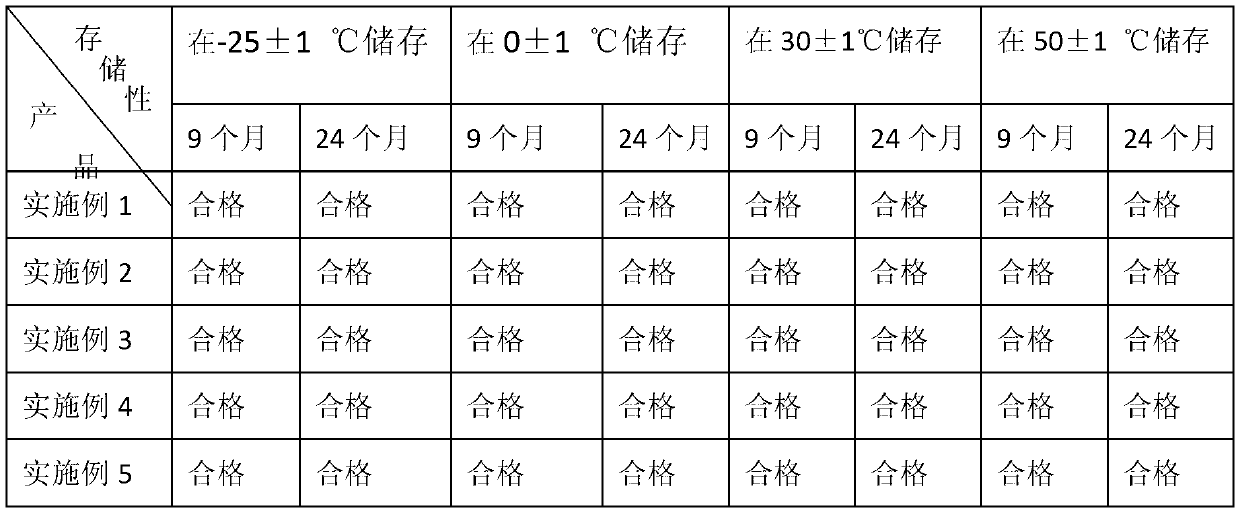

[0035] Add 40 parts of methyl silicone oil and 40 parts of white oil into the reaction kettle, mix and heat up to 40°C, then add 2 parts of sodium dodecylbenzenesulfonate, 2 parts of tributyl phosphate, 0.1 part of imidazoline, octadecyl 10 parts of acid, insulated and stirred for 30 minutes, then discharged, and cooled naturally.

[0036] The obtained product has a good demoulding effect after the JC / T945-2005 standard test, and the concrete adhesion after demoulding is 3.4g / m 2 .

Embodiment 2

[0038] Take 80 parts of white oil and add it to the reaction kettle, raise the temperature to 60°C, add 3 parts of sodium dodecylbenzenesulfonate, 201 parts of Tween, 1 part of tributyl phosphate, 0.04 parts of undecyl imidazoline, and 1 part of dodecyl acid , heat preservation and stirring for 30 minutes, discharge the material, and let it cool naturally.

[0039] The obtained product has good demoulding effect after JC / T945-2005 standard test, and the concrete adhesion after demoulding is 3.6g / m 2 .

Embodiment 3

[0041] Take 50 parts of ethyl silicone oil, 30 parts of dimethyl hydroxy silicone oil, and 10 parts of phenyl silicone oil, add them to the reaction kettle, mix and heat up to 50°C, 2 parts of sodium lauryl sulfate, 1 part of monoalkyl ether phosphate , 0.1 part of benzotriazole, 0.1 part of imidazoline, 0.1 part of ethanolamine, 2 parts of palmitic acid, and 3 parts of octadecanoic acid, keep stirring for 30 minutes, discharge the material, and let it cool naturally.

[0042] The obtained product has good demoulding effect after JC / T945-2005 standard test, and the concrete adhesion after demoulding is 3.6g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com