Polylactic acid / polyurethane blend and preparation method thereof

A polyester polyurethane and polylactic acid technology, applied in the field of polylactic acid/polyurethane blends and polylactic acid blends, can solve the problems of high brittleness of polylactic acid, and achieve the effect of improving toughness and tensile fracture strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The PLA homopolymer is 2002D (Natureworks company), and the weight-average molecular weight of the PLA homopolymer is 200,000; the polyester polyurethane is provided by Shandong Yantai Wanhua Polyurethane Co., Ltd.

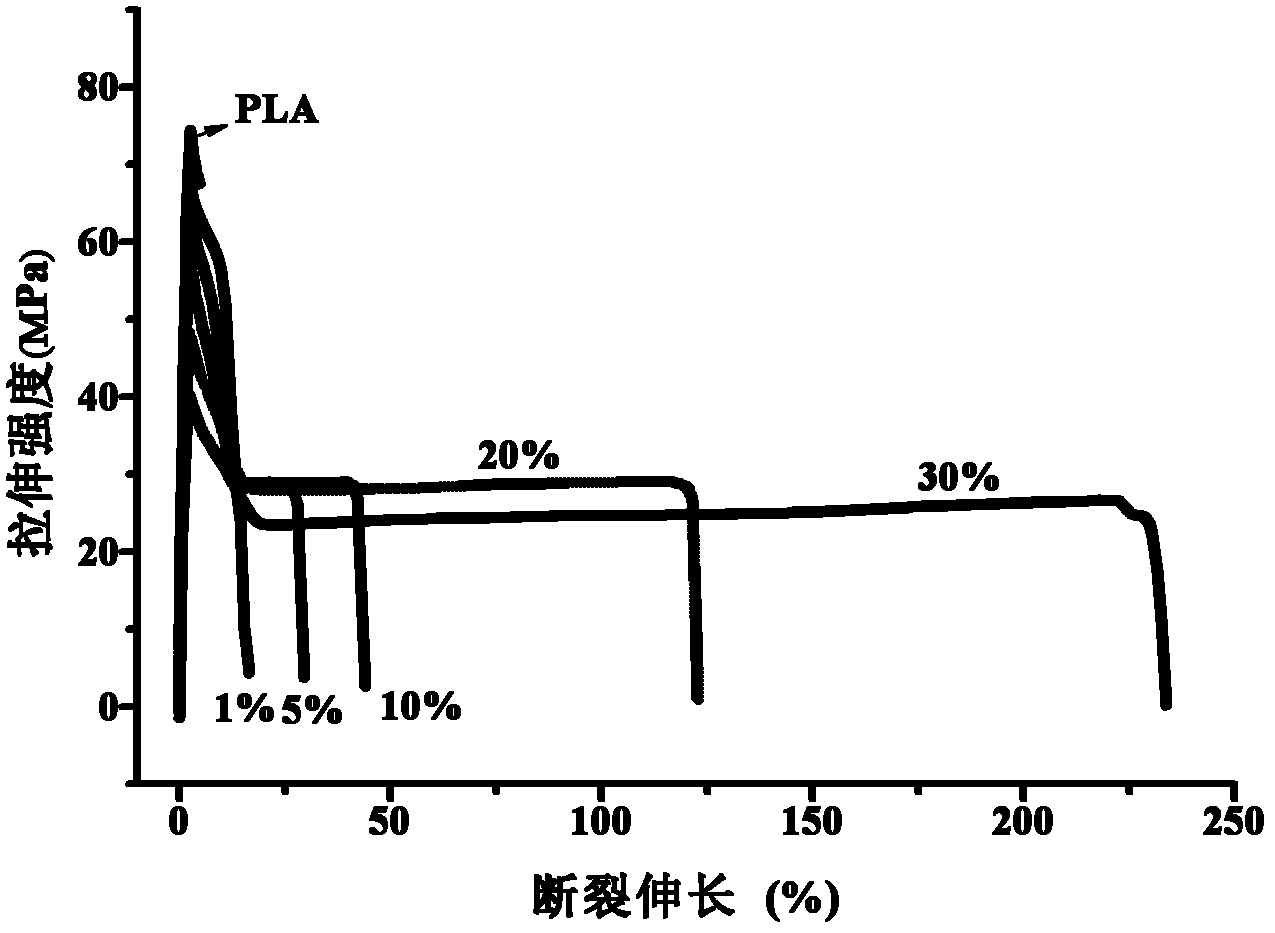

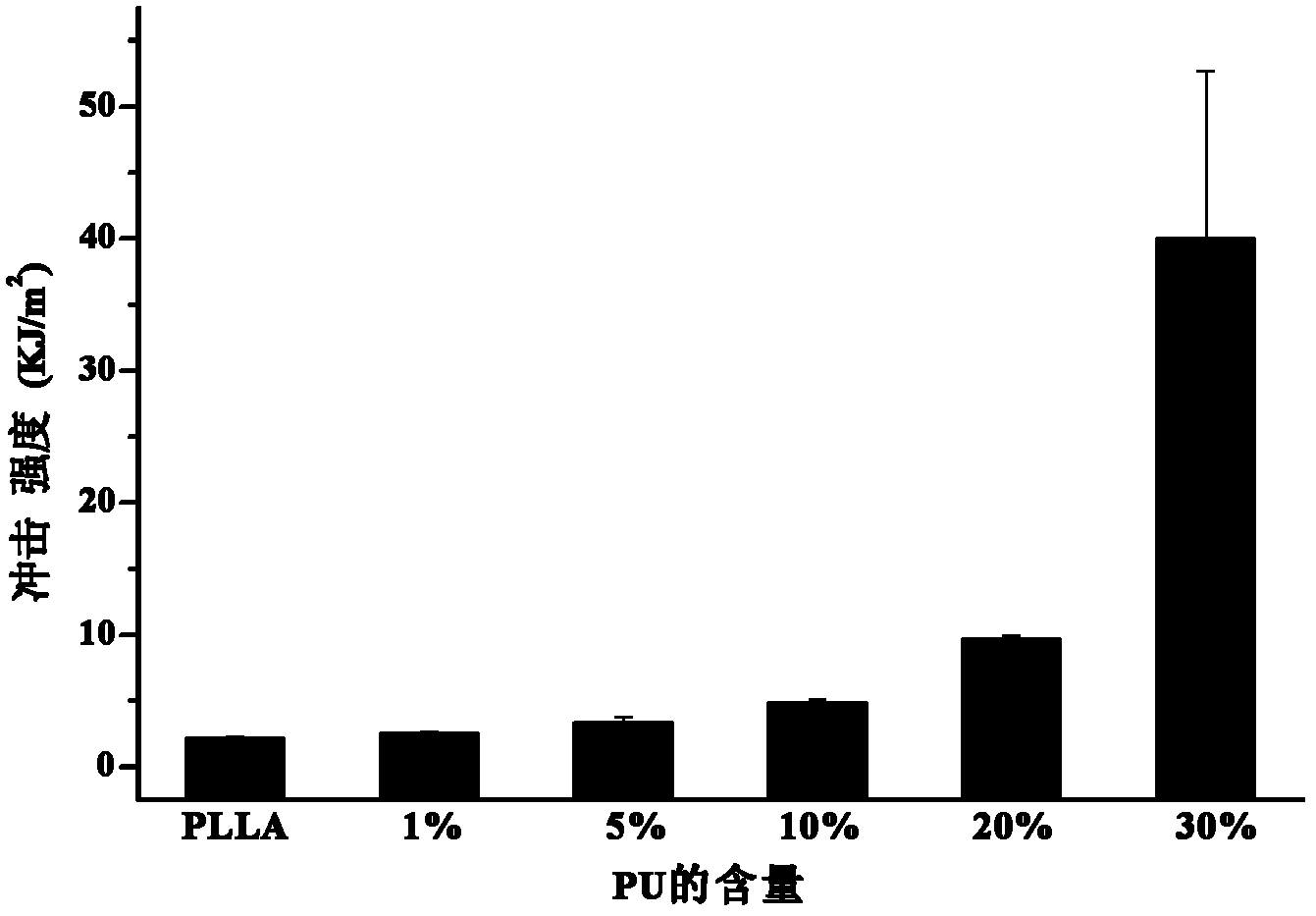

[0023] In terms of weight percentage, 99 parts of PLA homopolymer and 1 part of polyester polyurethane are uniformly mixed to obtain a mixture, and then the mixture is melt-blended with a twin-screw extruder at a temperature of 190-220°C to obtain PLA Blends with PU; the mechanical properties of the resulting PLA / PU blends can be found in figure 1 , 2 shown.

Embodiment 2

[0025] The PLA homopolymer is 2002D (Natureworks company), and the weight-average molecular weight of the PLA homopolymer is 200,000; the polyester polyurethane is provided by Shandong Yantai Wanhua Polyurethane Co., Ltd.

[0026] In terms of weight percentage, 95 parts of PLA homopolymer and 5 parts of polyester polyurethane are uniformly mixed to obtain a mixture, and then the mixture is melt-blended with a twin-screw extruder at a temperature of 190-220°C to obtain PLA Blends with PU; the mechanical properties of the resulting PLA / PU blends can be found in figure 1 , 2 shown.

Embodiment 3

[0028] The PLA homopolymer is 2002D (Natureworks company), and the weight-average molecular weight of the PLA homopolymer is 200,000; the polyester polyurethane is provided by Shandong Yantai Wanhua Polyurethane Co., Ltd.

[0029] In terms of weight percentage, 90 parts of PLA homopolymer and 10 parts of polyester polyurethane are uniformly mixed to obtain a mixture, and then the mixture is melt-blended with a twin-screw extruder at a temperature of 190-220°C to obtain PLA Blends with PU; the mechanical properties of the resulting PLA / PU blends can be found in figure 1 , 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com