Intra-tube forming machine of drainage tube

A drainage tube and molding machine technology, which is applied to tubular articles, other household appliances, household appliances, etc., can solve the problems of low processing efficiency, high labor intensity and high input cost, so as to reduce the failure rate and improve production and processing. Efficiency and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

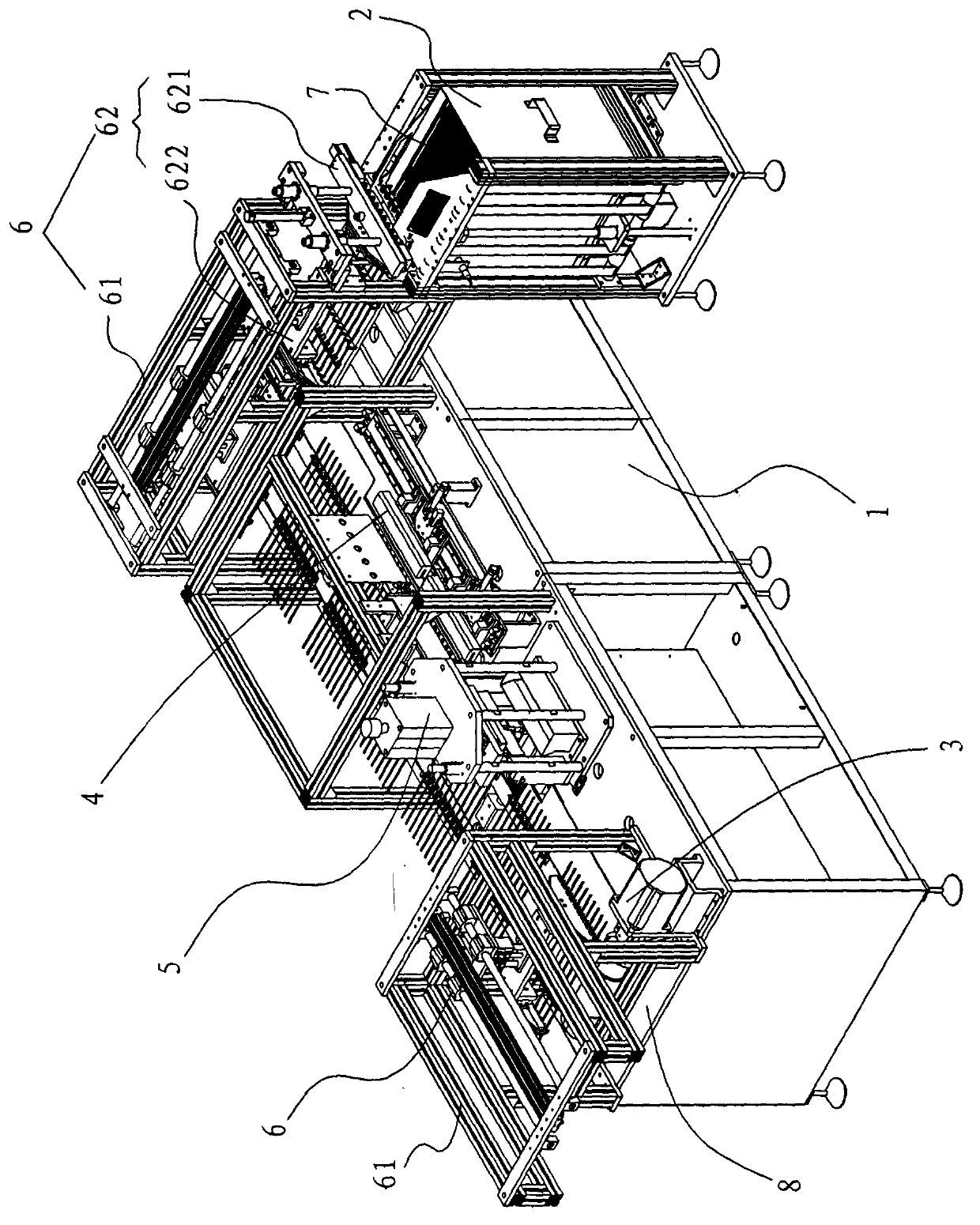

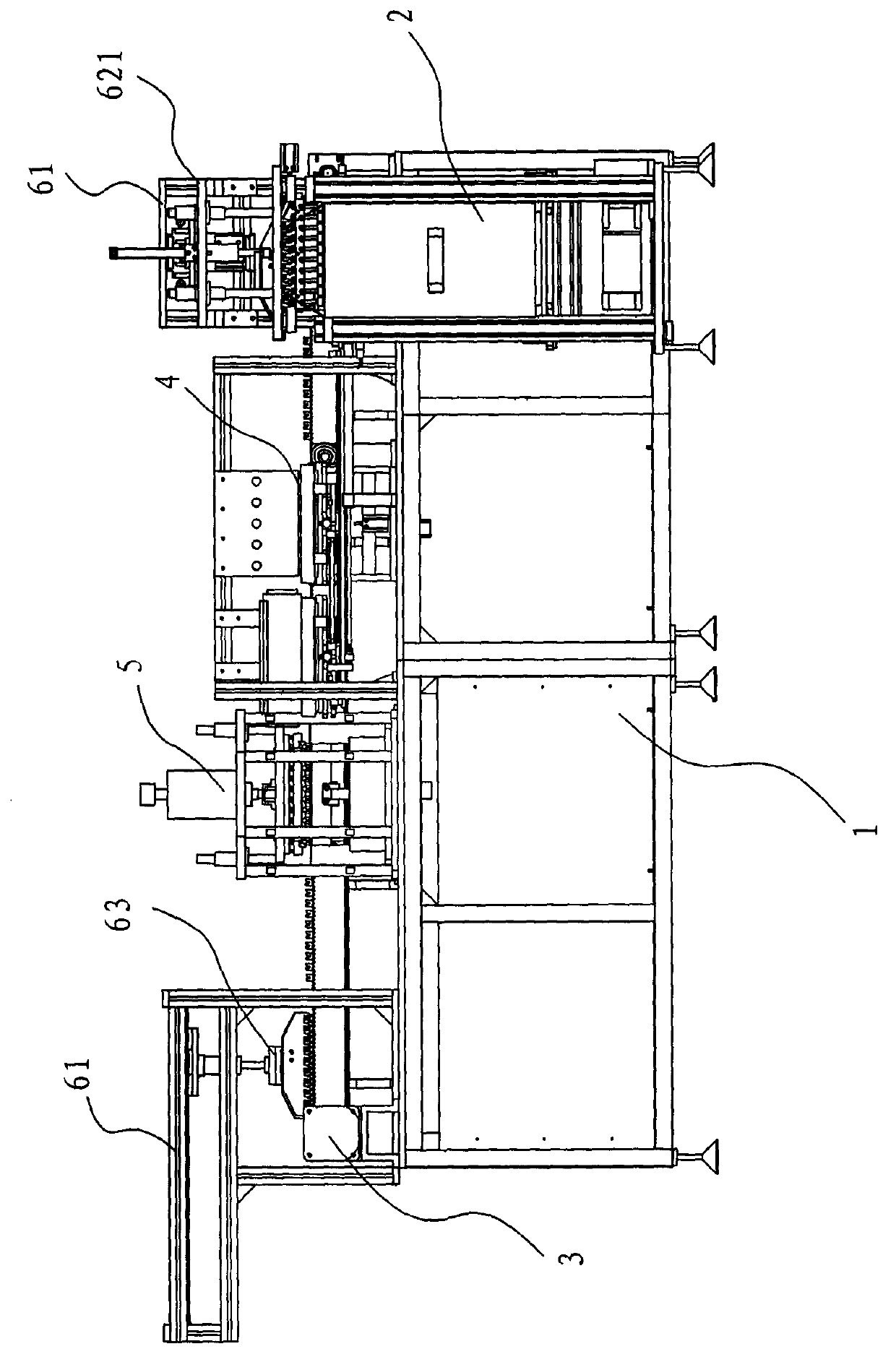

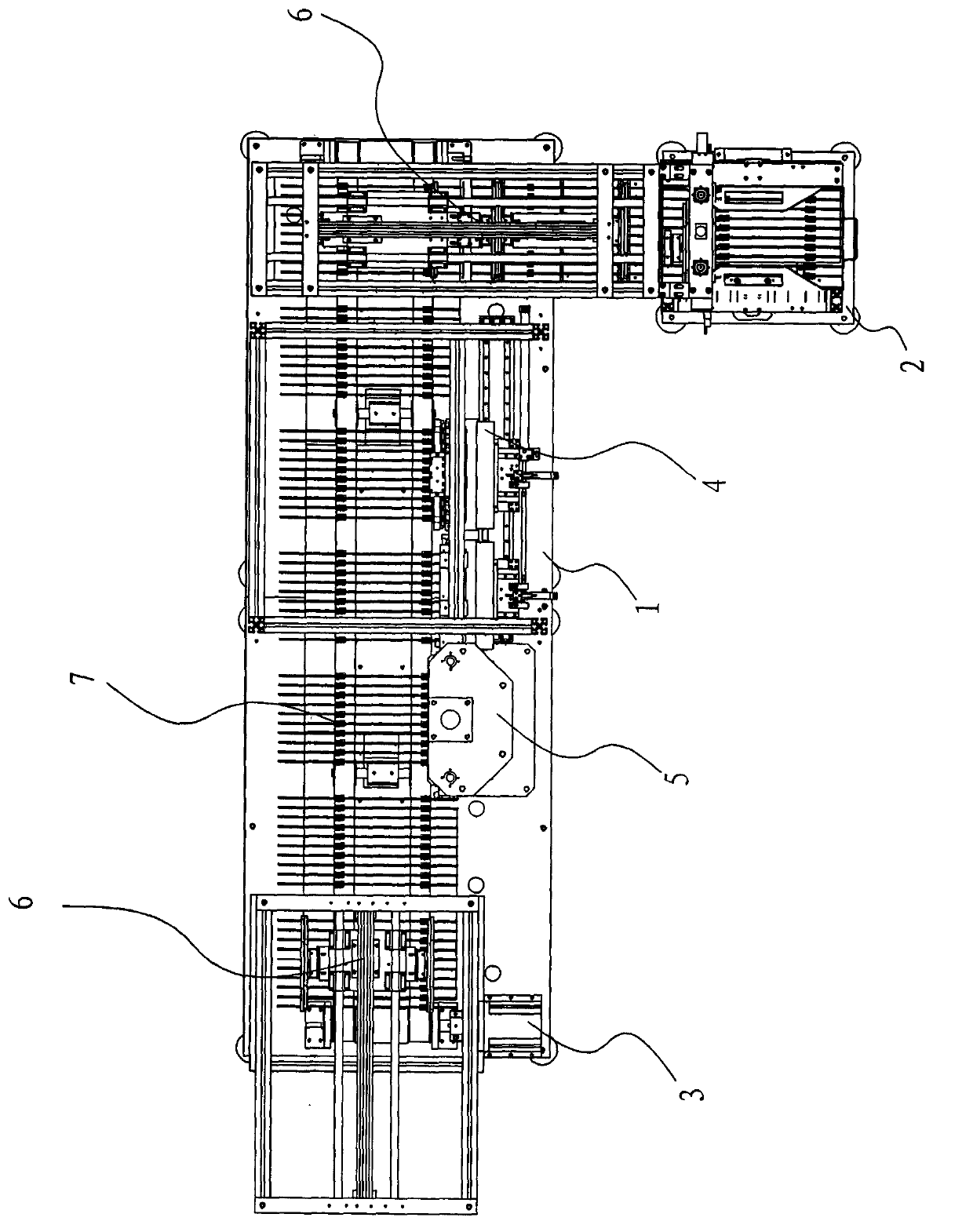

[0034] Example: see Figure 1 to Figure 4 As shown, a drainage tube inner molding machine, the tube inner molding machine includes a frame 1, a material loading box 2, a grabbing material handling assembly 3, a heating shrinkage assembly 4, an incision assembly 5 and a transmission assembly 6, and a plurality of drainage pipes 71 are composed of The clamp 72 clamps and forms the drainage tube assembly 7 .

[0035] see figure 1 and Figure 5 As shown, the feeding box 2 is located on one side of the frame 1, and it has a lifting mechanism 21 of a material chamber and a drainage tube assembly. A material box 22 is arranged in the material chamber, and the lifting mechanism 21 is a screw lifting mechanism; The upper end surface of the material loading box 2 is an opening surface 23, and the material holding chamber communicates with the opening surface 23 to form a feeding channel for the drainage tube assembly.

[0036] see figure 1 and Figure 6 As shown, the transmission a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com