Whole pollution-free manufacturing method for electrode containing electrolyte salt

An electrode manufacturing and electrolyte technology, applied in the field of electrode manufacturing containing electrolyte salt, to avoid pollution, improve power density, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

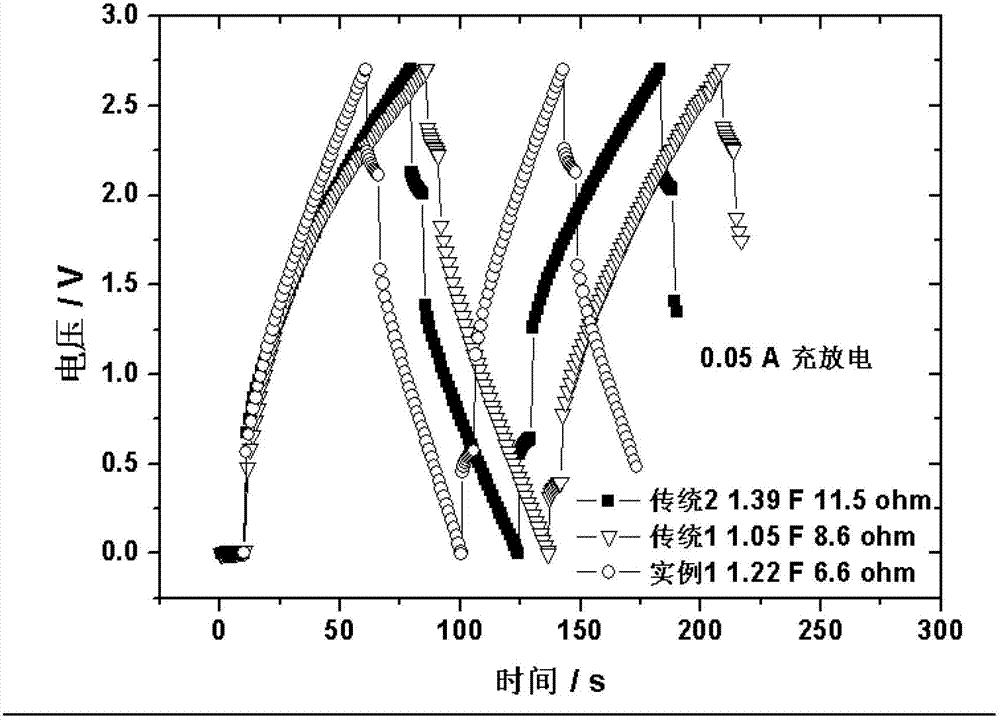

[0034] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiment (Example 1) and the accompanying drawings. This embodiment is only used to explain the present invention and does not constitute a limitation to the protection scope of the present invention.

[0035] Such as figure 1 As shown, a whole pollution-free supercapacitor electrode manufacturing method includes the following steps:

[0036] (1) Select V2 series activated carbon from EnerG2 Company of the United States, Super P Li conductive agent from Temego Company, PTFE binder from DuPont Company, and TEABF from Xinzhoubang Company 4 The electrolyte salt is transported to the three-dimensional mixer by quantitative metering for 20 minutes; the mass ratio of the four powders is 70:5:5:20; the delivery pipeline is a high-wear-resistant polytetrafluoroethylene pipeline; the three-dimensional mixer opening method The inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com